Pipe Fitings Alloy Steel 45° Elbow Therefore the 45 Degree Mitered Elbow produced by us have good mechanical as well as physical properties. For instance, ASME B16.9 45 Deg Elbow manufactured at our plant from any grade of stainless steel will have good corrosion resistance, a sturdy construction and will be durable. Besides Buttweld Elbow 45 Degree, we also 45 degree elbow manufacturers and other pipe fittings and Flanges

Due to frequent and rigorous quality check at all stages of production, the DIN 2605 45 Deg Elbow Type 3 produced at our factory is of the highest quality. The Stainless Steel 45 Degree Elbow has been designed in compliance with international quality standards

LR or the 45 Deg Elbow Long Radius have a Centre to Face dimension. This dimension of the 45 Deg Elbow is 1.5 X diameter and are considered to be the more common type. Hence, the 45 Deg Street Elbow can be used when space is available and when the flow is more critical.

| Specifications | ASME B16.9 45 Deg Elbow |

|---|---|

| ASME B16.9 elbow 45 degree size | Seamless Butt Weld Fittings: 1/2″ – 10″

Welded Butt Weld Fittings: 1/2″ – 48″ |

| 45 Deg Elbow Short RadiusType | DN15-DN1200 |

| 45 Deg Elbow Lr Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| 45 Deg Elbow Long Radius Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Carbon Steel 45 Degree Elbow Fitting Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| 45 Degree Pipe Elbow Size Range | ½” NB to 24″ NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| ASME B16.9 45 Deg Elbow Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for 45 Deg Street Elbow |

|

| 45 Deg Short Radius Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D,

4D,

5D, 6D, 7D-40D.

Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| 45 degree elbow manufacturers process for | Push, Press, forge, Cast, etc. |

| ASME B16.9 45 Deg Elbow Test Certificates | EN 10204/3.1B

Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Application for ASME B16.9 Elbow 45 Deg |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

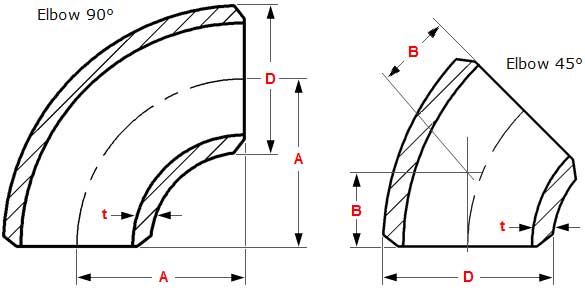

ASME B16.9 Elbow Radius & 45 Degree Elbow Dimensions

| NPS | O.D. D |

90 degrees Long Radius Center-to-End A |

45 degrees Long Radius Center-to-End B |

90 degrees 3D Center-to-End A |

45 degrees 3D Center-to-End B |

| 1/2 | 21.3 | 38 | 16 | – | – |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 964 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

| NPS | O.D. D |

Buttweld 90 degrees Long Radius Center-to-End A |

Buttweld 45 degrees Long Radius Center-to-End B |

Buttweld 90 degrees 3D Center-to-End A |

Buttweld 45 degrees 3D Center-to-End B |

| NPS | LBS | KG |

| 1/2 | 0.09 | 0.04 |

| 3/4 | 0.09 | 0.04 |

| 1 | 0.25 | 0.11 |

| 1.1/4 | 0.38 | 0.17 |

| 1.1/2 | 0.4 | 0.18 |

| 2 | 0.81 | 0.37 |

| 2.1/2 | 1.75 | 0.79 |

| 3 | 2.63 | 1.19 |

| 3.1/2 | 3.5 | 1.59 |

| 4 | 4.5 | 2.04 |

| 5 | 7.5 | 3.4 |

| 6 | 12 | 5.44 |

| 8 | 23 | 10.43 |

| 10 | 43 | 19.5 |

| 12 | 62 | 28.12 |

| 14 | 80 | 36.29 |

| 16 | 100 | 45.36 |

| 18 | 126 | 57.15 |

| 20 | 160 | 72.57 |

| 22 | 197 | 89.36 |

| 24 | 238 | 107.95 |

| 26 | 275 | 124.74 |

| 30 | 367 | 166.47 |

| 36 | 531 | 240.86 |

| NPS | LBS | KG |

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel |

Inside Ø at End |

Wall Thickness t / t1 |

Center to End Dim. A-B-C-M | Center to Center Dim. O |

Back to Face Dim. K |

Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |