Pipe Fittings Alloy Steel Reducing Tee A Reducing Tee Pipe Fitting is also referred to as a 3 way pipe fittings. Since the fittings resemble alphabet ‘T’, these fittings are known as tee fittings. A Reducing Tee Standard is a type of fitting where in two horizontal pipes can be attached with one vertical pipe. A Reducing Tee Carbon Steel is used to both manage the direction as well as the mixture of fluids. Pipe Reducing Tee A234 are widely used in piping systems. The primary function of these Reducing Tee Ductile Iron fittings is to transport two phase fluid mixtures. Tee fittings can be categorised into two main types of fittings ie - Equal Tee and Unequal Tee, otherwise known as a Reducing Tee.

Stainless Steel Reducing Tee Pipe Fitting can be achieved by either physical or mechanical surface treatment. For instance, chemically treating the surface of the Buttweld Unequal Tee includes coating the surface with chemicals via processes such as Hot Dipped Galvanizing, Epoxy & FBE Coating as well as Electro Polish. On the other hand, the chemical processes used for surface treatment of the Asme B16.9 Unequal Tee include methods such as - Sand Blasting, Threading, Soldering. Generally value added services impart the Grooved Reducing Tee & ASME B16.9 Lateral Tee with enhanced qualities. For e.g. - Galvanised Reducing Tee has a thick coat of zinc on its surface while Reducing Tee Joint can be coated with either black paint or anti rust oil to improve corrosion resistance in the fittings.

Outside Diameter of ASME B16.9 Reducing Tee Seamless Pipe fittings are available from the size range between ½ inch to about 24 inches. Different types of Reducing Tee Flanged fittings available in our stock include - ERW, Welded as well as Fabricated Pipe Tee. Wall Thickness of the Reducing Tee Bsp can be achieved in the following sizes 3mm – 40mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160 as well as XXS .

| Specifications | ASME B16.9 Reducing Tee |

|---|---|

| Ansi B16.9 Pipe Reducing Tee Fittings size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| Grooved Reducing Tee Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Pipe Reducing Tee Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Extruded Reducing Tee Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Reducing Tee Pipe Fitting Type | DN15-DN1200 |

| Connection for Asme B16.9 Unequal Tee | Welding |

| Ansi B16.9 Pipe Reducing Tee Fittings Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Buttweld Unequal Tee Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Grooved Reducing Tee Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D,

6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process for Reducing Tee Joint | Push, Press, Forge, Cast, etc. |

| Extruded Reducing Tee Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills For Galvanised Reducing Tee | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for ASME B16.9 Reducing Tee |

|

| Grooved Reducing Tee Application |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| Nominal Pipe Size | Outside diameter at bevel |

Center-to-End | |||

|---|---|---|---|---|---|

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

| 1/2" | 1/4" 3/8" |

21.3 | 13.7 17.3 |

25 | 25 |

| 3/4" | 3/8" 1/2" |

26.7 | 17.3 21.3 |

29 | 29 |

| 1" | 1/2" 3/4" |

33.4 | 21.3 26.7 |

38 | 38 |

| 1 1/4" | 1/2" 3/4" 1" |

42.2 | 21.3 26.7 33.4 |

48 | 48 |

| 1 1/2" | 1/2" 3/4" 1" 1 1/4" |

48.3 | 21.3 26.7 33.4 42.2 |

57 | 57 |

| 2" | 3/4" 1" 1 1/4" 1 1/2" |

60.3 | 26.7 33.4 42.2 48.3 |

64 | 44 51 57 60 |

| 2 1/2" | 1" 1 1/4" 1 1/2" 2" |

73.0 | 33.4 42.2 48.3 60.3 |

76 | 57 64 67 70 |

| 3" | 1 1/4" 1 1/2" 2" 2 1/2" |

88.9 | 42.2 48.3 60.3 73.0 |

86 | 70 73 76 83 |

| 3 1/2" | 1 1/2" 2" 2 1/2" 3" |

101.6 | 48.3 60.3 73.0 88.9 |

95 | 79 83 89 92 |

| 4" | 1 1/2" 2" 2 1/2" 3" 3 1/2" |

114.3 | 48.3 60.3 73.0 88.9 101.6 |

105 | 86 89 95 98 102 |

| 5" | 2" 2 1/2" 3" 3 1/2" 4" |

141.3 | 60.3 73.0 88.9 101.6 114.3 |

124 | 105 108 111 114 117 |

| 6" | 2 1/2" 3" 3 1/2" 4" 5 |

168.3 | 73.0 88.9 101.6 114.3 141.3 |

143 | 121 124 127 130 137 |

| 8" | 3 1/2" 4" 5" 6" |

219.1 | 101.6 114.3 141.3 168.3 |

178 | 152 156 162 168 |

| 10" | 4" 5" 6" 8" |

273.0 | 114.3 141.3 168.3 219.1 |

216 | 184 191 194 203 |

| 12" | 5" 6" 8" 10" |

323.8 | 141.3 168.3 219.1 273.0 |

254 | 216 219 229 241 |

| 14" | 6" 8" 10" 12" |

355.6 | 168.3 219.1 273.0 323.8 |

279 | 238 248 257 270 |

| 16" | 6" 8" 10" 12" 14" |

406.4 | 168.3 219.1 273.0 323.8 355.6 |

305 | 264 273 283 295 305 |

| 18" | 8" 10" 12" 14" 16" |

457.0 | 219.1 273.0 323.8 355.6 406.4 |

343 | 298 308 321 330 330 |

| 20" | 8" 10" 12" 14" 16" 18" |

508.0 | 219.1 273.0 323.8 355.6 406.4 457.0 |

381 | 324 333 346 356 356 368 |

| 22" | 10" 12" 14" 16" 18" 20" |

559.0 | 273.0 323.8 355.6 406.4 457.0 508.0 |

419 | 359 371 381 381 394 406 |

| 24" | 10" 12" 14" 16" 18" 20" 22" |

610.0 | 273.0 323.8 355.6 406.4 457.0 508.0 559.0 |

432 | 384 397 406 406 419 432 432 |

| NPS | LBS | KG |

| 1/2 | 0.35 | 0.16 |

| 3/4 | 0.45 | 0.2 |

| 1 | 0.75 | 0.34 |

| 1.1/4 | 1.3 | 0.59 |

| 1.1/2 | 2 | 0.91 |

| 2 | 3.5 | 1.59 |

| 2.1/2 | 6 | 2.72 |

| 3 | 7 | 3.18 |

| 3.1/2 | 9 | 4.08 |

| 4 | 12 | 5.44 |

| 5 | 21 | 9.53 |

| 6 | 34 | 15.42 |

| 8 | 55 | 24.95 |

| 10 | 85 | 38.56 |

| 12 | 120 | 54.43 |

| 14 | 165 | 74.84 |

| 16 | 195 | 88.45 |

| 18 | 249 | 112.94 |

| 20 | 342 | 155.13 |

| 22 | 414 | 187.79 |

| 24 | 528 | 239.5 |

| 26 | 770 | 349.27 |

| 30 | 1060 | 480.81 |

| 36 | 1490 | 675.85 |

| NPS | LBS | KG |

|

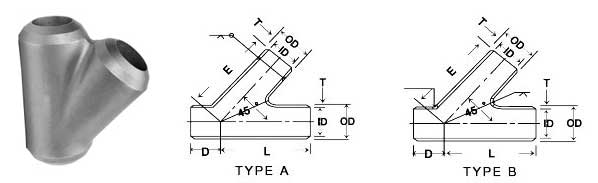

Nominal

Pipe Size |

TYPE

|

Outside

Diameter OD |

STD

|

X – S

|

NPS

|

||||||

|

E & L

|

D

|

T

|

ID

|

E & L

|

D

|

T

|

ID

|

||||

|

1

1¼ 1½ |

B

B B |

1.315

1.660 1.900 |

5.75

6.25 7.00 |

1.75

1.75 2.00 |

0.133

0.140 0.145 |

1.049

1.380 1.610 |

6.50

7.25 8.50 |

2.00

2.25 2.50 |

0.179

0.191 0.200 |

0.957

1.278 1.500 |

1

1¼ 1½ |

|

2

2½ 3 |

A/B

B B |

2.375

2.875 3.500 |

8.00

9.50 10.00 |

2.50

2.50 3.00 |

0.154

0.203 0.216 |

2.067

2.469 3.068 |

*8.00

**9.00 10.50 11.00 |

2.50

2.50 3.00 |

0.128

0.276 0.300 |

1.939

2.323 2.900 |

2

2½ 3 |

|

3½

4 5 |

B

A/B B |

4.000

4.500 5.562 |

11.50

12.00 13.50 |

3.00

3.00 3.50 |

0.226

0.237 0.258 |

3.548

4.026 5.047 |

12.50

*12.00 **13.50 15.00 |

3.00

3.00 3.50 |

0.318

0.337 0.375 |

3.364

3.826 4.813 |

3½

4 5 |

|

6

8 10 |

A/B

B B |

6.625

8.625 10.750 |

14.50

17.50 20.50 |

3.50

4.50 5.00 |

0.280

0.322 0.365 |

6.065

7.981 10.020 |

*14.50

**17.50 20.50 24.00 |

*3.50

**4.00 5.00 5.50 |

0.432

0.500 0.500 |

5.761

7.625 9.750 |

6

8 10 |

|

12

14 16 |

B

B B |

12.750

14.000 16.000 |

24.50

27.00 30.00 |

5.50

6.00 6.50 |

0.375

0.375 0.375 |

12.000

13.250 15.250 |

27.50

31.00 34.50 |

6.00

6.50 7.50 |

0.500

0.500 0.500 |

11.750

13.000 15.000 |

12

14 16 |

|

18

20 24 |

B

B B |

18.000

20.000 24.000 |

32.00

35.00 40.50 |

7.00

8.00 9.00 |

0.375

0.375 0.375 |

17.250

19.250 23.250 |

37.50

40.50 47.50 |

8.00

8.50 10.00 |

0.500

0.500 0.500 |

17.000

19.000 23.000 |

18

20 24 |

| NPS | LBS | KG |

| 1/2 | 0.36 | 0.16 |

| 3/4 | 0.58 | 0.26 |

| 1 | 1 | 0.45 |

| 1.1/4 | 2 | 0.91 |

| 1.1/2 | 3 | 1.36 |

| 2 | 5 | 2.27 |

| 2.1/2 | 8 | 3.63 |

| 3 | 10 | 4.54 |

| 3.1/2 | – | – |

| 4 | 25 | 11.34 |

| 5 | 55 | 24.95 |

| 6 | 62 | 28.12 |

| 8 | 110 | 49.9 |

| 10 | 260 | 117.93 |

| 12 | 480 | 217.72 |

| NPS | LBS | KG |