Pipe Fittings Alloy AS 180° Elbow The 180 Deg Elbow Dimensions produced at our factory can be made according to the following Standards - ANSI, B16.9, ASME, DIN2650, 2615, 2616, 2617 JIS B2311, 2312, 2313, EN 10253-11, EN10253-2 . The types of Elbow 180 Degree include Seamless, Welded as well as Fabricated ones.

An AS (Alloy Steel) 180° elbow is a type of pipe fitting used to change the direction of the pipeline by a complete 180-degree bend. This fitting allows the pipeline to reverse its direction entirely. It is designed to connect two pipes of the same nominal diameter but in completely opposite directions.

A 180 Degree Elbow, is also referred to as a 180 bend or 180 ell. The DIN 2605 180 Deg Elbow Type 3 is commonly used in diverse sectors such as Oil and Gas Industry , Nuclear Industry, Pulp &Paper Industry, Petro-Chemical Industry, Research & Development , Mega Projects as well as the Defense & Development Industries. In fact owing to the special grade of steel 180 Degree Mitered Elbow could be used for all critical applications

| Specifications | ASME B16.9 180 Deg Elbow |

|---|---|

| ASME B16.9 elbow 180 degree size | Seamless Butt Weld Fittings: 1/2″ – 10″ Welded Butt Weld Fittings: 1/2″ – 48″ |

| 180 Deg Elbow Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Elbow 180 Sch 40 Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| 180 Deg Elbow Short Radius Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| 180 Deg Elbow LrType | DN15-DN1200 |

| Connection For Stainless Steel 180 Deg Elbow Long Radius | Welding |

| 180 Degree Elbow Fitting Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| 180 Degree Pipe Elbow Size Range | ½” NB to 24″ NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Carbon Steel SCH 80 180 Degree Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D,

5D,

6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process For 180 Deg Street Elbow | Push, Press, forge, Cast, etc. |

| 180 Deg Short Radius Elbow Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills For 180 Degree Compression Elbow | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for ASME B16.9 Elbow 180 Deg |

|

| Application For Elbow 180 Sch 10 |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

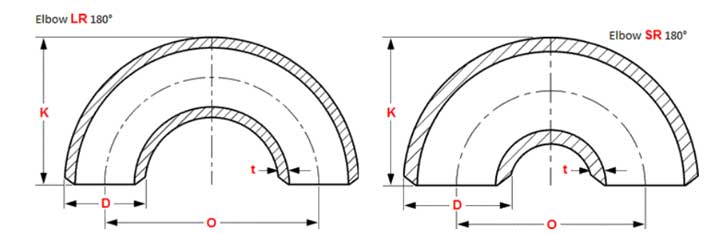

| NPS | O.D. D |

180deg Long Rad | 180deg Short Rad | ||

| Center to Center O |

Back to Face K |

Center to Center O |

Back to Face K |

||

| 1/2 | 21.3 | 76 | 48 | … | … |

| 3/4 | 26.7 | 76 | 51 | … | … |

| 1 | 33.4 | 76 | 56 | 51 | 41 |

| 1.1/4 | 42.2 | 95 | 70 | 64 | 52 |

| 1.1/2 | 48.3 | 114 | 83 | 76 | 62 |

| 2 | 60.3 | 152 | 106 | 102 | 81 |

| 2.1/2 | 73 | 190 | 132 | 127 | 100 |

| 3 | 88.9 | 229 | 159 | 152 | 121 |

| 3.1/2 | 101.6 | 267 | 184 | 178 | 140 |

| 4 | 114.3 | 305 | 210 | 203 | 159 |

| 5 | 141.3 | 381 | 262 | 254 | 197 |

| 6 | 168.3 | 457 | 313 | 305 | 237 |

| 8 | 219.1 | 610 | 414 | 406 | 313 |

| 10 | 273 | 762 | 518 | 508 | 391 |

| 12 | 323.8 | 914 | 619 | 610 | 467 |

| 14 | 355.6 | 1067 | 711 | 711 | 533 |

| 16 | 406.4 | 1219 | 813 | 813 | 610 |

| 18 | 457 | 1372 | 914 | 914 | 686 |

| 20 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 559 | 1676 | 1118 | 1118 | 838 |

| 24 | 610 | 1829 | 1219 | 1219 | 914 |

| NPS | O.D. D |

180deg Long Rad | 180deg Short Rad | ||

| Center to Center O |

Back to Face K |

Center to Center O |

Back to Face K |

||

| WEIGHTS OF FITTINGS | ||||||||

| NPSinches | ELBOWSLR 180° | ELBOWSSR 180° | ||||||

| Sch.5S | Sch.10S | Sch.40S | Sch.80S | Sch.5S | Sch.10S | Sch.40S | Sch.80S | |

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.180 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.180 | 1.20 |

| 3 | 0.180 | 1.30 | 2.00 | 2.180 | 0.60 | 0.180 | 1.35 | 1.180 |

| 4 | 1.40 | 2.00 | 4.00 | 5.180 | 0.180 | 1.35 | 2.65 | 3.180 |

| 5 | 2.180 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.180 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 180/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Øat Bevel | Inside Øat End | Wall Thicknesst / t1 | Center to End Dim. A-B-C-M | Center to Center Dim.O | Back to Face Dim.K | Align- ment of EndsU |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |