Pipe Fittings High Alloy Steel Equal Tee A high alloy steel equal tee is a type of pipe fitting that plays a crucial role in connecting three pipes of the same diameter to create a T-shaped junction. The term "high alloy steel" refers to a type of steel alloy that contains a higher percentage of alloying elements compared to standard carbon steel. These alloying elements can include chromium, nickel, molybdenum, and others, which enhance the mechanical properties and corrosion resistance of the steel.

It's important to note that the specific details of a high alloy steel equal tee can vary based on the manufacturer, the intended application, and the industry standards to which it adheres. Users should always refer to the product specifications provided by the manufacturer for accurate and detailed information.

The Bw Equal Tee manufactured in our factor is from superior grade raw materials. We specialize in the manufacture of Reducing Tee Dimensions Asme B16 9 which are used to create multiple connections of pipes.

The Equal Tee Asme B16.9 offered by us are widely used in wide array of industries such as shipbuilding, power generation, oil & gas, pulp and paper mills, petrochemical wastewater treatment plants, and pharmaceutical plants. These seamless & welded Barred Equal Tee typically conform to dimensional standard ANSI B 16.9. This specification of Asme B16 9 Tees is available in classes between 2000 to 9000. The thickness of the Unequal Tee is available from Schedules from 10 to 160 as well .

| Specifications | ASME B16.9 Equal Tee Fitting |

|---|---|

| Asme B16 9 Tee size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| ASME B16.9 Equal Tee Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Tee Dimensions Asme B16 9 Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Unequal Tee Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Equal Tee And Reducing Tee Type | DN15-DN1200 |

| Connection For Equal And Unequal Tee | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Equal Tee Asme B16.9 Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Barred Equal Tee Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D,

5D,

6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process for Bw Equal Tee | Push, Press, Forge, Cast, etc. |

| Cast Iron Equal Tee Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills for Carbon Steel Equal Tee | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Copper Equal Tee |

|

| Equal Flow Tee Application |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

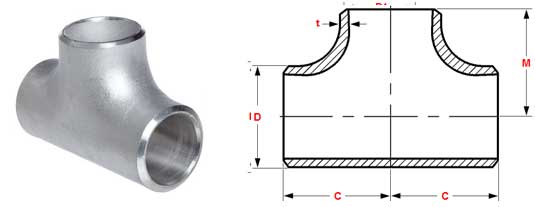

| ominal Pipe Size | Outside diameter at bevel |

Center-to-End | |

|---|---|---|---|

| Run (C) | Outlet(M) | ||

| 1/2" | 21.3 | 25 | 25 |

| 3/4" | 26.7 | 29 | 29 |

| 1" | 33.4 | 38 | 38 |

| 1 1/4" | 42.2 | 48 | 48 |

| 1 1/2" | 48.3 | 57 | 57 |

| 2" | 60.3 | 64 | 64 |

| 2 1/2" | 73.0 | 76 | 76 |

| 3" | 88.9 | 86 | 86 |

| 3 1/2" | 101.6 | 95 | 95 |

| 4" | 114.3 | 105 | 105 |

| 5" | 141.3 | 124 | 124 |

| 6" | 168.3 | 143 | 143 |

| 8" | 219.1 | 178 | 178 |

| 10" | 273.0 | 216 | 216 |

| 12" | 323.8 | 254 | 254 |

| 14" | 355.6 | 279 | 279 |

| 16" | 406.4 | 305 | 305 |

| 18" | 457.0 | 343 | 343 |

| 20" | 508.0 | 381 | 381 |

| 22" | 559.0 | 419 | 419 |

| 24" | 610.0 | 432 | 432 |

| NPS | LBS | KG |

|---|---|---|

| 1/2 | 0.35 | 0.16 |

| 3/4 | 0.45 | 0.2 |

| 1 | 0.75 | 0.34 |

| 1.1/4 | 1.3 | 0.59 |

| 1.1/2 | 2 | 0.91 |

| 2 | 3.5 | 1.59 |

| 2.1/2 | 6 | 2.72 |

| 3 | 7 | 3.18 |

| 3.1/2 | 9 | 4.08 |

| 4 | 12 | 5.44 |

| 5 | 21 | 9.53 |

| 6 | 34 | 15.42 |

| 8 | 55 | 24.95 |

| 10 | 85 | 38.56 |

| 12 | 120 | 54.43 |

| 14 | 165 | 74.84 |

| 16 | 195 | 88.45 |

| 18 | 249 | 112.94 |

| 20 | 342 | 155.13 |

| 22 | 414 | 187.79 |

| 24 | 528 | 239.5 |

| 26 | 770 | 349.27 |

| 30 | 1060 | 480.81 |

| 36 | 1490 | 675.85 |

| NPS | LBS | KG |