Pipe Fitings Titanium Butt weld Stub End A Titanium butt weld stub end is a type of pipe fitting used in piping systems for applications where a disassemblable joint is required. Butt weld stub ends are often used in conjunction with lap joint flanges to create a connection that can be easily taken apart. Here are some key features and details about Titanium butt weld stub ends

When using Titanium butt weld stub ends, it's essential to follow proper installation procedures, consider the specific requirements of the application, and adhere to industry standards. Professional consultation and adherence to relevant guidelines can provide specific details on the selection, installation, and maintenance of Titanium butt weld stub ends in a given system.

The stub end is made of titanium, a metal known for its corrosion resistance, high strength-to-weight ratio, and suitability for use in challenging environments.Short Pattern: These stub ends have a shorter length and are typically used in low-pressure applications.

| Type Butt weld (BW) Standard | Butt weld (BW) | |

| ASME / ANSI – B 16.9 | ||

| ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 | ||

| ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings’ | ||

| ASME B16.25 – ‘Buttwelding Ends’ | ||

| ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ | ||

| MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ | ||

| Butt Weld Stub End Dimension | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 | |

| Butt Weld Stub End Size | 1/2” TO 36”, (Seamless Butt weld up to 24”), (Welded Butt weld 8” TO 36”) | |

| Butt Weld Stub End Thickness | SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS, Custom Thickness. | |

| Butt weld fittings Range | Elbow, Tee, Reducer, Stubend, Cross, Pipe Cap, Pipe Bend | |

| Stainless Steel Butt Weld Stub End | ASTM A403 WP316/316L ASTM A403 WP304/304L ASTM A182 F316L, 304L DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 | |

| Low Temperature Butt Weld Stub End | ASTM A420 WPL3, A420 WPL6 | |

| Alloy Steel Butt Weld Stub End | ASTM A 234 WP – P5, P9, P11, P12, P21, P22 & P91 ASTM A234 wp1 / wp5 / wp9 / wp11 / wp22 / wp91 | |

| Copper Alloys Butt Weld Stub End | ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500 ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10) , C 71500 (CU -NI- 70/30) | |

| Nickel Alloy Butt Weld Stub End | ASTM / ASME SB 366, ASTM / ASME SB 564, Inconel 600 – UNS N06600, Inconel 601 – UNS N06601, Inconel 625 – UNS N06625, Incoloy 800 – UNS N08800, Incoloy 800H / HT – UNS N08810, Incoloy 825 – UNS N08825 |

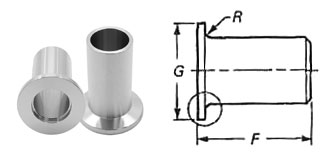

| Nominal Pipe Size

(NPS) |

Outside Diameter at Bevel | Long Pattern | Short Pattern | Radius of Fillet | Diameter of Lap | |

|---|---|---|---|---|---|---|

| Max | Min | F | F | R | G | |

| 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 35 |

| 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 43 |

| 1 | 35.0 | 32.6 | 102 | 51 | 3 | 51 |

| 1-1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 64 |

| 1-1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 73 |

| 2 | 62.4 | 59.5 | 152 | 64 | 8 | 92 |

| 2-1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 105 |

| 3 | 91.3 | 88.1 | 152 | 64 | 10 | 127 |

| 3-1/2 | 104.0 | 100.8 | 152 | 76 | 10 | 140 |

| 4 | 116.7 | 113.5 | 152 | 76 | 11 | 157 |

| 5 | 144.3 | 140.5 | 203 | 76 | 11 | 186 |

| 6 | 171.3 | 167.5 | 203 | 89 | 13 | 216 |

| 8 | 222.1 | 218.3 | 203 | 102 | 13 | 270 |

| 10 | 277.2 | 272.3 | 254 | 127 | 13 | 324 |

| 12 | 328.0 | 323.1 | 254 | 152 | 13 | 381 |

| 14 | 359.5 | 354.8 | 305 | 152 | 13 | 413 |

| 16 | 411.0 | 405.6 | 305 | 152 | 13 | 470 |

| 18 | 462 | 456 | 305 | 152 | 13 | 533 |

| 20 | 514 | 507 | 305 | 152 | 13 | 584 |

| 22 | 565 | 558 | 305 | 152 | 13 | 641 |

| 24 | 616 | 609 | 305 | 152 | 13 | 692 |

All dimensions are in millimeters.

|

DIMENSIONAL TOLERANCES – STUB ENDS |

||||||

|---|---|---|---|---|---|---|

| For all fittings | Stub Ends | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Indide Ø at End | Wall Thickness t / t1 |

O.D. of Lap G | Fillet Radius of Lap – R | Overall Length. – F |

|

1/2 a 2 1/2

|

1

|

0,8

|

Not

|

+0 -1

|

+0-1

|

2

|

|

3 a 3 1/2

|

1

|

1,6

|

less

|

+0 -1

|

+0-1

|

2

|

|

4

|

+2 -1

|

1,6

|

than

|

+0 -1

|

+0 -2

|

2

|

|

5 a 6

|

+3 -1

|

1,6

|

87,50%

|

+0-1

|

+0 -2

|

2

|

|

8

|

2

|

1,6

|

of nominal

|

+0 -1

|

+0 -2

|

2

|

|

10

|

+4 -3

|

3,2

|

tickness

|

+0 -2

|

+0 -2

|

2

|

|

12 to 18

|

+4-3

|

3,2

|

+0 -2

|

+0-2

|

3

|

|

|

20 a 24

|

+6-5

|

4,8

|

+0 -2

|

+0 -2

|

3

|

|

|

26 a 30

|

+7 -5

|

4,8

|

||||

|

32 a 48

|

+7 -5

|

4,8

|

||||

|

NPS

inches |

STUB ENDS

|

|||

|---|---|---|---|---|

|

Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

|

|

1/2

|

0.06

|

0.08

|

0.12

|

0.13

|

|

3/4

|

0.07

|

0.09

|

0.15

|

0.17

|

|

1

|

0.09

|

0.15

|

0.20

|

0.25

|

|

1 1/4

|

0.13

|

0.20

|

0.30

|

0.35

|

|

1 1/2

|

0.16

|

0.25

|

0.38

|

0.46

|

|

2

|

0.25

|

0.40

|

0.55

|

0.75

|

|

2 1/2

|

0.35

|

0.50

|

0.80

|

1.00

|

|

3

|

0.50

|

0.60

|

1.10

|

1.50

|

|

4

|

0.70

|

1.00

|

1.80

|

2.50

|

|

5

|

1.00

|

1.25

|

2.50

|

3.50

|

|

6

|

1.60

|

1.95

|

3.70

|

5.50

|

|

8

|

2.50

|

3.10

|

5.90

|

10.0

|

|

10

|

4.00

|

4.90

|

10.5

|

14.0

|

|

12

|

6.60

|

7.10

|

15.0

|

20.0

|

|

14

|

6.40

|

7.80

|

15.5

|

20.5

|

|

16

|

7.90

|

9.00

|

18.0

|

24.0

|

|

18

|

9.30

|

10.5

|

21.0

|

28.0

|

|

20

|

12.0

|

13.5

|

23.5

|

31.0

|

|

24

|

16.5

|

19.0

|

28.5

|

38.0

|

|

Approximate weights in kg, density 8

kg/dm3

|

||||

| NOMINAL PIPE SIZE (Inches) | NB | OD | THICKNESS | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 80 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 15NB | 21.30 | 1.65 | 2.11 | __ | 2.41 | 2.77 | 3.73 |

| 3/4 | 20NB | 26.70 | 1.65 | 2.11 | __ | 2.41 | 2.87 | 3.91 |

| 1 | 25NB | 33.40 | 1.65 | 2.77 | __ | 2.90 | 3.38 | 4.55 |

| 1 1/4 | 32NB | 42.20 | 1.65 | 2.77 | __ | 2.97 | 3.56 | 4.85 |

| 1 1/2 | 40NB | 48.30 | 1.65 | 2.77 | __ | 3.18 | 3.68 | 5.08 |

| 2 | 50NB | 60.30 | 1.65 | 2.77 | __ | 3.18 | 3.91 | 5.54 |

| 2 1/2 | 65NB | 73.00 | 2.11 | 3.05 | __ | 4.78 | 5.16 | 7.01 |

| 3 | 80NB | 88.90 | 2.11 | 3.05 | __ | 4.78 | 5.49 | 7.62 |

| 3 1/2 | 90NB | 101.60 | 2.11 | 3.05 | __ | 4.78 | 5.74 | 8.08 |

| 4 | 100NB | 114.30 | 2.11 | 3.05 | __ | 4.78 | 6.02 | 8.56 |

| 5 | 125NB | 141.30 | 2.77 | 3.40 | __ | __ | 6.55 | 9.53 |

| 6 | 150NB | 168.30 | 2.77 | 3.40 | __ | __ | 7.11 | 10.97 |

| 8 | 200NB | 219.10 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 12.70 |

| 10 | 250NB | 273.00 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 15.09 |

| 12 | 300NB | 323.80 | 3.96 | 4.57 | 6.35 | 8.38 | 10.31 | 17.48 |

| 14 | 350NB | 355.60 | 3.96 | 6.35 | 7.92 | 9.53 | 11.13 | 19.05 |

| 16 | 400NB | 406.40 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 | 21.44 |

| 18 | 450NB | 457.00 | 4.19 | 6.35 | 7.92 | 11.13 | 14.27 | 23.83 |

| 20 | 500NB | 508.00 | 4.78 | 6.35 | 9.53 | 12.70 | 15.09 | 26.19 |

| 22 | 550NB | 559.00 | 4.78 | 6.35 | 9.53 | 12.70 | __ | 28.58 |

| 24 | 600NB | 610.00 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 30.96 |

Facing: 125-250 RMS (smooth finish)

w = welded version

s = seamless execution

| Nominal | Schedule | D | t | G | F | R. Max. | kg / St. | |

|---|---|---|---|---|---|---|---|---|

| 1/2 " | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 " | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 " | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 " | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 " | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 " | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 " | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 " | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 " | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 " | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 " | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 " | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 " | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 " | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 " | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 " | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 " | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 " | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 " | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |