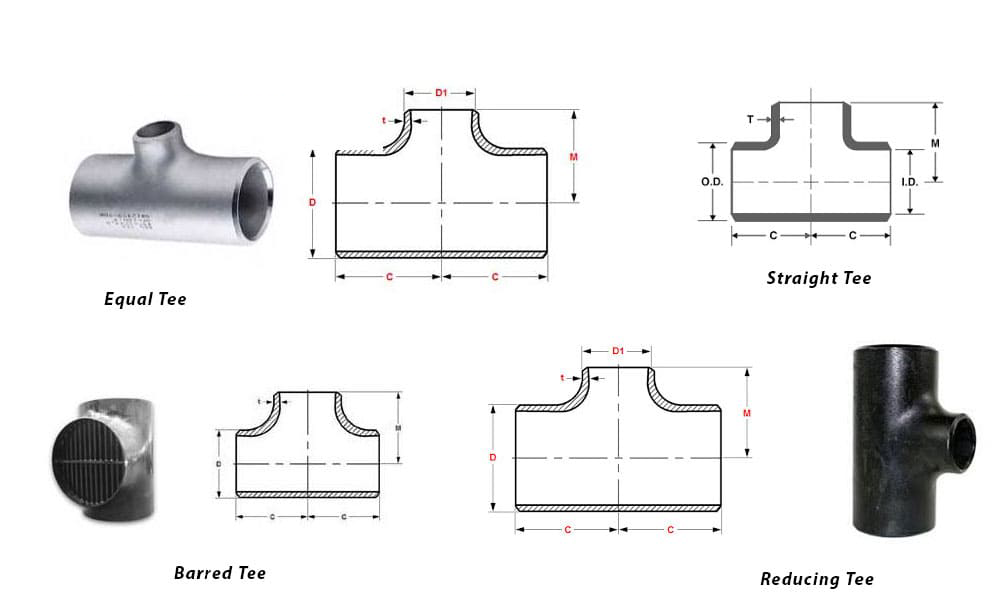

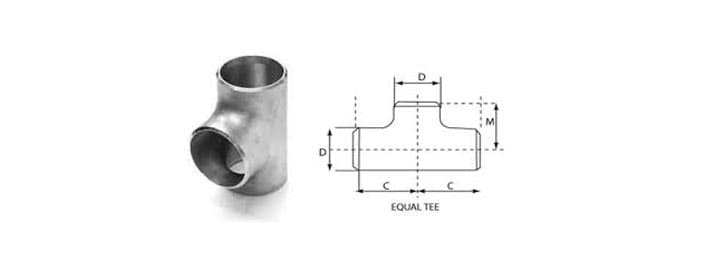

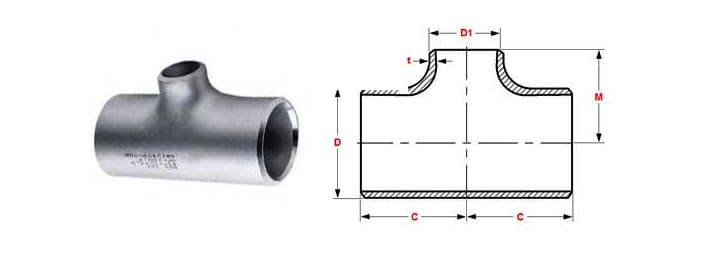

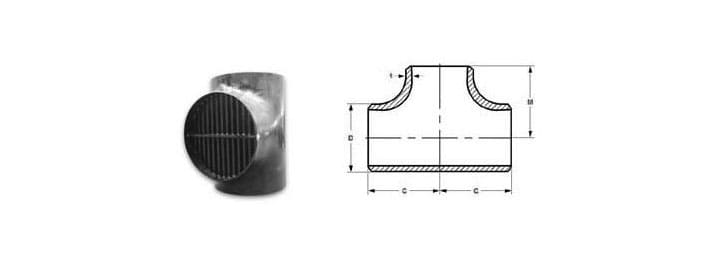

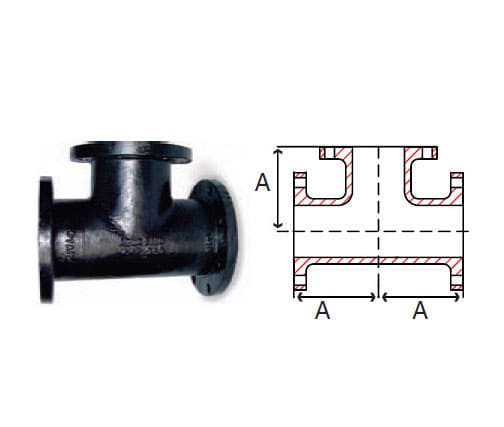

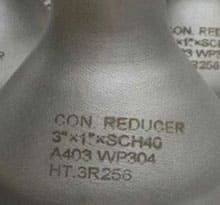

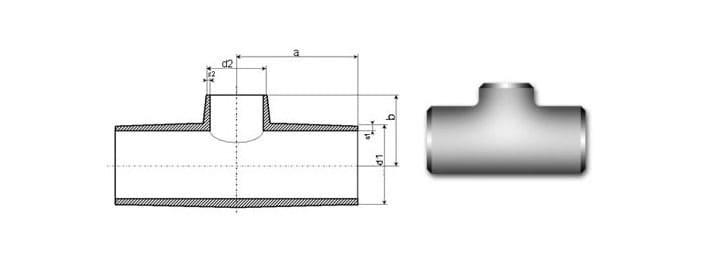

ASME B16.9 Tee The ASME B16. 9 Carbon Steel Equal Tee is made up of carbon steel materials. There are ferritic and austenitic types of stainless steels that are used for the production of the Stainless Steel Equal Tee Fitting as well. Reducing Tee Carbon Steel, this Fittings like all pipe tees, is within the form of 'T' with 2 ends of equal size and therefore the third one slightly smaller. Reducing Tee Ductile Iron Fittings provides a high integrity mechanical connections in various pumping applications. The other Applications for the Carbon Steel Reducing Tee A234 which is distributed and Supplied by us are Food and Beverage, Shipbuilding, Water Treatment, Chemical Processing, Cooling and Refrigeration, etc. The ASME B16.9 Reducing Tee is usually described as NPS diameters in 4" x 4" x 3", where 4" is the main line pipe diameter, and 3" is the reducing branch.

| NPS Of ASME B16.9 Equal Tees | O.D. (Outer Daimeter) at bevel |

Center-End | |

|---|---|---|---|

| Run (C) | Outlet (M) | ||

| 1/2" | 21.3 | 25 | 25 |

| 3/4" | 26.7 | 29 | 29 |

| 1" | 33.4 | 38 | 38 |

| 1 1/4" | 42.2 | 48 | 48 |

| 1 1/2" | 48.3 | 57 | 57 |

| 2" | 60.3 | 64 | 64 |

| 2 1/2" | 73.0 | 76 | 76 |

| 3" | 88.9 | 86 | 86 |

| 3 1/2" | 101.6 | 95 | 95 |

| 4" | 114.3 | 105 | 105 |

| 5" | 141.3 | 124 | 124 |

| 6" | 168.3 | 143 | 143 |

| 8" | 219.1 | 178 | 178 |

| 10" | 273.0 | 216 | 216 |

| 12" | 323.8 | 254 | 254 |

| 14" | 355.6 | 279 | 279 |

| 16" | 406.4 | 305 | 305 |

| 18" | 457.0 | 343 | 343 |

| 20" | 508.0 | 381 | 381 |

| 22" | 559.0 | 419 | 419 |

| 24" | 610.0 | 432 | 432 |

| NPS Of ASME B16.9 Reducing Tees | O.D. (Outer Daimeter) at bevel |

Center-End | |||

|---|---|---|---|---|---|

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

| 1/2" | 1/4" 3/8" |

21.3 | 13.7 17.3 |

25 | 25 |

| 3/4" | 3/8" 1/2" |

26.7 | 17.3 21.3 |

29 | 29 |

| 1" | 1/2" 3/4" |

33.4 | 21.3 26.7 |

38 | 38 |

| 1 1/4" | 1/2" 3/4" 1" |

42.2 | 21.3 26.7 33.4 |

48 | 48 |

| 1 1/2" | 1/2" 3/4" 1" 1 1/4" |

48.3 | 21.3 26.7 33.4 42.2 |

57 | 57 |

| 2" | 3/4" 1" 1 1/4" 1 1/2" |

60.3 | 26.7 33.4 42.2 48.3 |

64 | 44 51 57 60 |

| 2 1/2" | 1" 1 1/4" 1 1/2" 2" |

73.0 | 33.4 42.2 48.3 60.3 |

76 | 57 64 67 70 |

| 3" | 1 1/4" 1 1/2" 2" 2 1/2" |

88.9 | 42.2 48.3 60.3 73.0 |

86 | 70 73 76 83 |

| 3 1/2" | 1 1/2" 2" 2 1/2" 3" |

101.6 | 48.3 60.3 73.0 88.9 |

95 | 79 83 89 92 |

| 4" | 1 1/2" 2" 2 1/2" 3" 3 1/2" |

114.3 | 48.3 60.3 73.0 88.9 101.6 |

105 | 86 89 95 98 102 |

| 5" | 2" 2 1/2" 3" 3 1/2" 4" |

141.3 | 60.3 73.0 88.9 101.6 114.3 |

124 | 105 108 111 114 117 |

| 6" | 2 1/2" 3" 3 1/2" 4" 5 |

168.3 | 73.0 88.9 101.6 114.3 141.3 |

143 | 121 124 127 130 137 |

| 8" | 3 1/2" 4" 5" 6" |

219.1 | 101.6 114.3 141.3 168.3 |

178 | 152 156 162 168 |

| 10" | 4" 5" 6" 8" |

273.0 | 114.3 141.3 168.3 219.1 |

216 | 184 191 194 203 |

| 12" | 5" 6" 8" 10" |

323.8 | 141.3 168.3 219.1 273.0 |

254 | 216 219 229 241 |

| 14" | 6" 8" 10" 12" |

355.6 | 168.3 219.1 273.0 323.8 |

279 | 238 248 257 270 |

| 16" | 6" 8" 10" 12" 14" |

406.4 | 168.3 219.1 273.0 323.8 355.6 |

305 | 264 273 283 295 305 |

| 18" | 8" 10" 12" 14" 16" |

457.0 | 219.1 273.0 323.8 355.6 406.4 |

343 | 298 308 321 330 330 |

| 20" | 8" 10" 12" 14" 16" 18" |

508.0 | 219.1 273.0 323.8 355.6 406.4 457.0 |

381 | 324 333 346 356 356 368 |

| 22" | 10" 12" 14" 16" 18" 20" |

559.0 | 273.0 323.8 355.6 406.4 457.0 508.0 |

419 | 359 371 381 381 394 406 |

| 24" | 10" 12" 14" 16" 18" 20" 22" |

610.0 | 273.0 323.8 355.6 406.4 457.0 508.0 559.0 |

432 | 384 397 406 406 419 432 432 |

| NPS Of ASME B16.9 Straight Tees | Outer Daimeter D |

Center-End C |

Center-End M |

| 1/2 | 21.3 | 25 | 25 |

| 3/4 | 26.7 | 29 | 29 |

| 1 | 33.4 | 38 | 38 |

| 1 1/2 | 42.2 | 48 | 48 |

| 1½ | 48.3 | 57 | 57 |

| 2 | 60.3 | 64 | 64 |

| 2½ | 73 | 76 | 76 |

| 3 | 88.9 | 86 | 86 |

| 3½ | 101.6 | 95 | 95 |

| NPS Of ASME B16.9 Barred Tees | Outer Daimeter at bevel |

Center-End | |||

|---|---|---|---|---|---|

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

| 1/2" | 1/4" 3/8" |

21.3 | 13.7 17.3 |

25 | 25 |

| 3/4" | 3/8" 1/2" |

26.7 | 17.3 21.3 |

29 | 29 |

| 1" | 1/2" 3/4" |

33.4 | 21.3 26.7 |

38 | 38 |

| 1 1/4" | 1/2" 3/4" 1" |

42.2 | 21.3 26.7 33.4 |

48 | 48 |

| 1 1/2" | 1/2" 3/4" 1" 1 1/4" |

48.3 | 21.3 26.7 33.4 42.2 |

57 | 57 |

| 2" | 3/4" 1" 1 1/4" 1 1/2" |

60.3 | 26.7 33.4 42.2 48.3 |

64 | 44 51 57 60 |

| 2 1/2" | 1" 1 1/4" 1 1/2" 2" |

73.0 | 33.4 42.2 48.3 60.3 |

76 | 57 64 67 70 |

| 3" | 1 1/4" 1 1/2" 2" 2 1/2" |

88.9 | 42.2 48.3 60.3 73.0 |

86 | 70 73 76 83 |

| 3 1/2" | 1 1/2" 2" 2 1/2" 3" |

101.6 | 48.3 60.3 73.0 88.9 |

95 | 79 83 89 92 |

| 4" | 1 1/2" 2" 2 1/2" 3" 3 1/2" |

114.3 | 48.3 60.3 73.0 88.9 101.6 |

105 | 86 89 95 98 102 |

| 5" | 2" 2 1/2" 3" 3 1/2" 4" |

141.3 | 60.3 73.0 88.9 101.6 114.3 |

124 | 105 108 111 114 117 |

| 6" | 2 1/2" 3" 3 1/2" 4" 5 |

168.3 | 73.0 88.9 101.6 114.3 141.3 |

143 | 121 124 127 130 137 |

| 8" | 3 1/2" 4" 5" 6" |

219.1 | 101.6 114.3 141.3 168.3 |

178 | 152 156 162 168 |

| 10" | 4" 5" 6" 8" |

273.0 | 114.3 141.3 168.3 219.1 |

216 | 184 191 194 203 |

| 12" | 5" 6" 8" 10" |

323.8 | 141.3 168.3 219.1 273.0 |

254 | 216 219 229 241 |

| 14" | 6" 8" 10" 12" |

355.6 | 168.3 219.1 273.0 323.8 |

279 | 238 248 257 270 |

| 16" | 6" 8" 10" 12" 14" |

406.4 | 168.3 219.1 273.0 323.8 355.6 |

305 | 264 273 283 295 305 |

| 18" | 8" 10" 12" 14" 16" |

457.0 | 219.1 273.0 323.8 355.6 406.4 |

343 | 298 308 321 330 330 |

| 20" | 8" 10" 12" 14" 16" 18" |

508.0 | 219.1 273.0 323.8 355.6 406.4 457.0 |

381 | 324 333 346 356 356 368 |

| 22" | 10" 12" 14" 16" 18" 20" |

559.0 | 273.0 323.8 355.6 406.4 457.0 508.0 |

419 | 359 371 381 381 394 406 |

| 24" | 10" 12" 14" 16" 18" 20" 22" |

610.0 | 273.0 323.8 355.6 406.4 457.0 508.0 559.0 |

432 | 384 397 406 406 419 432 432 |

| NPS | OD For (Outside Diameter) |

TYPE | X – S | STD | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (E And L) | (D) | (T) | (Inner Daimeter) | (E And L) | (D) | (T) | (Inner Daimeter) | |||

| 1 1¼ 1½ |

1.315 1.660 1.900 |

B B B |

6.50 7.25 8.50 |

2.00 2.25 2.50 |

0.179 0.191 0.200 |

0.957 1.278 1.500 |

5.75 6.25 7.00 |

1.75 1.75 2.00 |

0.133 0.140 0.145 |

1.049 1.380 1.610 |

| 2 2½ 3 |

2.375 2.875 3.500 |

A/B B B |

*8.00 **9.00 10.50 11.00 |

2.50 2.50 3.00 |

0.128 0.276 0.300 |

1.939 2.323 2.900 |

8.00 9.50 10.00 |

2.50 2.50 3.00 |

0.154 0.203 0.216 |

2.067 2.469 3.068 |

| 3½ 4 5 |

4.000 4.500 5.562 |

B A/B B |

12.50 *12.00 **13.50 15.00 |

3.00 3.00 3.50 |

0.318 0.337 0.375 |

3.364 3.826 4.813 |

11.50 12.00 13.50 |

3.00 3.00 3.50 |

0.226 0.237 0.258 |

3.548 4.026 5.047 |

| 6 8 10 |

6.625 8.625 10.750 |

A/B B B |

*14.50 **17.50 20.50 24.00 |

*3.50 **4.00 5.00 5.50 |

0.432 0.500 0.500 |

5.761 7.625 9.750 |

14.50 17.50 20.50 |

3.50 4.50 5.00 |

0.280 0.322 0.365 |

6.065 7.981 10.020 |

| 12 14 16 |

12.750 14.000 16.000 |

B B B |

27.50 31.00 34.50 |

6.00 6.50 7.50 |

0.500 0.500 0.500 |

11.750 13.000 15.000 |

24.50 27.00 30.00 |

5.50 6.00 6.50 |

0.375 0.375 0.375 |

12.000 13.250 15.250 |

| 18 20 24 |

18.000 20.000 24.000 |

B B B |

37.50 40.50 47.50 |

8.00 8.50 10.00 |

0.500 0.500 0.500 |

17.000 19.000 23.000 |

32.00 35.00 40.50 |

7.00 8.00 9.00 |

0.375 0.375 0.375 |

17.250 19.250 23.250 |

ASME B16.9 Tee are widely used in various commercial and industrial applications Like:

| Parameter | ASME B16.9 Tee | ASME B16.9 Barred Tee |

| Definition | Standard Pipe Fitting | A special type of piping component |

| Manufacturing | Generally by Extrusion or forging | Mostly Fabricated |

| Use | Used in both piping and pipeline engineering | used in pipeline engineering near the pig launcher/receiver |

| Design Code / Standard | ASME B 16.9/MSS SP 75 | Shell DEP 31.40.10.13-Gen or ISO 15590-2 |

| Production Quantity | Large scale in bulk | Select small quantities (custom made) |

| Cost | Cheaper | Costlier than normal Tee |

| Grade and Marking Symbol | Alloy Steel WP11 CL3 Fittings, WP22 CL3 Fittings, WP2 CL3 Fittings, WP9 CL3 Fittings |

| Tensile strength, range Ksi [MPa] | 75-100 [520-690] |

| Yield strength, minimum, Ksi [MPa] (0.2% offset or 0.5% extension- under-load) | 45 [310] |

| Specification Format | ASME B16.9 Tee |

|---|---|

| Manufacturer Type Of Pipe Tee | Reducing/ Equal/ Unequal/ Lateral/ Straight/ Barred/ Split |

| Equal Tees Use | Stainless Steel Equal Tees used to connect 2 pipes |

| Reducing Tees Use | Stainless Steel helps in reducing the diameter of the pipe that have been connected. |

| Unequal Tees Use | Stainless Steel Unequal Tees are usually made up of copper and is used in aqueous and acidic environment owing to its resistance to corrosion and oxidation |

| Barred Tees Use | Stainless Steel Barred Tees is made up of carbon steel material i.e ferritic, and austenitic type |

| Macking Methods | ButtWeld Welded Seamless |

| Schedule | SCH 5S To SCH 180. |

| Standard And Dimensions | JIS B2313 EN 10253-2 MSS SP-75 BS 4825 EN 10253-4 JIS B2312 |

| Manufacturer Size | NPS 1⁄₂ To NPS 48 |

| NPS Of ASME B16.9 Tee | Steel Pipe Tees Weight In LBS | SS Tees Fitting Weight In (KG) Kilogram |

| 1/2 | 0.35 | 0.16 |

| 3/4 | 0.45 | 0.2 |

| 1 | 0.75 | 0.34 |

| 1.1/4 | 1.3 | 0.59 |

| 1.1/2 | 2 | 0.91 |

| 2 | 3.5 | 1.59 |

| 2.1/2 | 6 | 2.72 |

| 3 | 7 | 3.18 |

| 3.1/2 | 9 | 4.08 |

| 4 | 12 | 5.44 |

| 5 | 21 | 9.53 |

| 6 | 34 | 15.42 |

| 8 | 55 | 24.95 |

| 10 | 85 | 38.56 |

| 12 | 120 | 54.43 |

| 14 | 165 | 74.84 |

| 16 | 195 | 88.45 |

| 18 | 249 | 112.94 |

| 20 | 342 | 155.13 |

| 22 | 414 | 187.79 |

| 24 | 528 | 239.5 |

| 26 | 770 | 349.27 |

| 30 | 1060 | 480.81 |

| 36 | 1490 | 675.85 |

| Normal Size Of Steel Pipe Of ASME B16.9 Equal Tees | (Outer Daimeter) For O.D. | Center-End | Manufacturer Length |

|---|---|---|---|

| Length In Inch | Outer Daimeter (O.D.) | (C) | (M) |

| 1/2 | 21.3 | 25 | 25 |

| 3/4 | 26.7 | 29 | 29 |

| 1 | 33.4 | 38 | 38 |

| 1 1/4 | 42.2 | 48 | 48 |

| 1 1/2 | 48.3 | 57 | 57 |

| 2 | 60.3 | 64 | 64 |

| 2 1/2 | 73 | 76 | 76 |

| 3 | 88.9 | 86 | 86 |

| 3 1/2 | 101.6 | 95 | 95 |

| 4 | 114.3 | 105 | 105 |

| 5 | 141.3 | 124 | 124 |

| 6 | 168.3 | 143 | 143 |

| 8 | 219.1 | 178 | 178 |

| 10 | 273.1 | 216 | 216 |

| 12 | 323.9 | 254 | 254 |

| 14 | 355.6 | 279 | 279 |

| 16 | 406.4 | 305 | 305 |

| 18 | 457.2 | 343 | 343 |

| 20 | 508 | 381 | 381 |

| 22 | 559 | 419 | 419 |

| 24 | 610 | 432 | 432 |

| 26 | 660 | 495 | 495 |

| 28 | 711 | 521 | 521 |

| 30 | 762 | 559 | 559 |

| 32 | 813 | 597 | 597 |

| 34 | 864 | 635 | 635 |

| 36 | 914 | 673 | 673 |

| 38 | 965 | 711 | 711 |

| NPS Of ASME B16.9 Reducing Tees | Stainless Steel Reducing Tees Weight In LBS | Carbon Steel Reducing Tees Weight In KG (Kilogram) |

| 1/2 | 0.35 | 0.16 |

| 3/4 | 0.45 | 0.2 |

| 1 | 0.75 | 0.34 |

| 1.1/4 | 1.3 | 0.59 |

| 1.1/2 | 2 | 0.91 |

| 2 | 3.5 | 1.59 |

| 2.1/2 | 6 | 2.72 |

| 3 | 7 | 3.18 |

| 3.1/2 | 9 | 4.08 |

| 4 | 12 | 5.44 |

| 5 | 21 | 9.53 |

| 6 | 34 | 15.42 |

| 8 | 55 | 24.95 |

| Stainless Steel Tees Pressure Ratings | |||||

|---|---|---|---|---|---|

| ASME B16.9 Tees Temperature Ratings | Types Of Pressure Ratings Class | ||||

| Class 150# | Class 300# | ||||

| 1/4 - 1 (Inch) | 1 1/4 - 2 (Inch) | 2 1/2 - 3 (Inch) | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

| Normal Size Of Pipe (DN) |

Schedule Number |

Outer Daimeter In inch millmeter |

Wall Thickness inch millmeter |

Mass lb/ft kg/m |

|---|---|---|---|---|

| 1/8 6 |

5S | 0.405 10.3 |

... | ... |

| 1/8 6 |

10S | 0.405 10.3 |

0.049 1.24 |

0.19 0.28 |

| 1/8 6 |

40S | 0.405 10.3 |

0.068 1.73 |

0.24 0.37 |

| 1/8 6 |

80S | 0.405 10.3 |

0.095 2.41 |

0.31 0.47 |

| 1/4 8 |

5S | 0.540 13.7 |

... | ... |

| 1/4 8 |

10S | 0.540 13.7 |

0.065 1.65 |

0.33 0.49 |

| 1/4 8 |

40S | 0.540 13.7 |

0.088 2.24 |

0.43 0.63 |

| 1/4 8 |

80S | 0.540 13.7 |

0.119 3.02 |

0.54 0.80 |

| 3/8 10 |

5S | 0.675 17.1 |

... | ... |

| 3/8 10 |

10S | 0.675 17.1 |

0.065 1.65 |

0.42 0.63 |

| 3/8 10 |

40S | 0.675 17.1 |

0.091 2.31 |

0.57 0.84 |

| 3/8 10 |

80S | 0.675 17.1 |

0.126 3.20 |

0.74 1.10 |

| 1/2 15 |

5S | 0.840 21.3 |

0.065 1.65 |

0.54 0.80 |

| 1/2 15 |

10S | 0.840 21.3 |

0.083 2.11 |

0.67 1.00 |

| 1/2 15 |

40S | 0.840 21.3 |

0.109 2.77 |

0.85 1.27 |

| 1/2 15 |

80S | 0.840 21.3 |

0.147 3.73 |

1.09 1.62 |

| 3/4 20 |

5S | 1.050 26.7 |

0.065 1.65 |

0.68 1.02 |

| 3/4 20 |

10S | 1.050 26.7 |

0.083 2.11 |

0.86 1.28 |

| 3/4 20 |

40S | 1.050 26.7 |

0.113 2.87 |

1.13 1.69 |

| 3/4 20 |

80S | 1.050 26.7 |

0.154 3.91 |

1.48 2.20 |

| 1 25 |

5S | 1.315 33.4 |

0.065 1.65 |

0.68 1.02 |

| 1 25 |

10S | 1.315 33.4 |

0.083 2.11 |

0.86 1.28 |

| 1 25 |

40S | 1.315 33.4 |

0.133 3.38 |

1.68 2.50 |

| 1 25 |

80S | 1.315 33.4 |

0.179 4.55 |

2.17 3.24 |

| 1-1/4 32 |

5S | 1.660 42.2 |

0.065 1.65 |

1.11 1.65 |

| 1-1/4 32 |

10S | 1.660 42.2 |

0.109 2.77 |

1.81 2.69 |

| 1-1/4 32 |

40S | 1.660 42.2 |

0.140 3.56 |

2.27 3.39 |

| 1-1/4 32 |

80S | 1.660 42.2 |

0.191 4.85 |

3.00 4.47 |

| 1-1/2 40 |

5S | 1.900 48.3 |

0.065 1.65 |

1.28 1.90 |

| 1-1/2 40 |

10S | 1.900 48.3 |

0.109 2.77 |

2.09 3.11 |

| 1-1/2 40 |

40S | 1.900 48.3 |

0.145 3.68 |

2.72 4.05 |

| 1-1/2 40 |

80S | 1.900 48.3 |

0.200 5.08 |

3.63 5.41 |

| 2 50 |

5S | 2.375 60.3 |

0.065 1.65 |

1.61 2.39 |

| 2 50 |

10S | 2.375 60.3 |

0.109 2.77 |

2.64 3.93 |

| 2 50 |

40S | 2.375 60.3 |

0.154 3.91 |

3.66 5.44 |

| 2 50 |

80S | 2.375 60.3 |

0.218 5.54 |

5.03 7.48 |

| 2-1/2 65 |

5S | 2.875 73 |

0.083 2.11 |

2.48 3.69 |

| 2-1/2 65 |

10S | 2.875 73 |

0.120 3.05 |

3.53 5.26 |

| 2-1/2 65 |

40S | 2.875 73 |

0.203 5.16 |

5.80 8.63 |

| 2-1/2 65 |

80S | 2.875 73 |

0.276 7.01 |

7.67 11.41 |

| 3 80 |

5S | 3.500 88.9 |

0.083 2.11 |

3.03 4.52 |

| 3 80 |

10S | 3.500 88.9 |

0.120 3.05 |

4.34 6.46 |

| 3 80 |

40S | 3.500 88.9 |

0.216 5.49 |

7.58 11.29 |

| 3 80 |

80S | 3.500 88.9 |

0.300 7.62 |

10.26 15.27 |

| 3-1/2 90 |

5S | 4.000 101.6 |

0.083 2.11 |

3.48 5.18 |

| 3-1/2 90 |

10S | 4.000 101.6 |

0.120 3.05 |

4.98 7.41 |

| 3-1/2 90 |

40S | 4.000 101.6 |

0.226 5.74 |

9.12 13.57 |

| 3-1/2 90 |

80S | 4.000 101.6 |

0.318 8.08 |

12.52 18.64 |

| 4 100 |

5S | 4.500 114.3 |

0.083 2.11 |

3.92 5.84 |

| 4 100 |

10S | 4.500 114.3 |

0.120 3.05 |

5.62 8.37 |

| 4 100 |

40S | 4.500 114.3 |

0.237 6.02 |

10.80 16.08 |

| 4 100 |

80S | 4.500 114.3 |

0.337 8.56 |

15.00 22.32 |

| 5 125 |

5S | 5.563 141.3 |

0.109 2.77 |

6.36 9.46 |

| 5 125 |

10S | 5.563 141.3 |

0.134 3.40 |

7.78 11.56 |

| 5 125 |

40S | 5.563 141.3 |

0.258 6.55 |

14.63 21.77 |

| 5 125 |

80S | 5.563 141.3 |

0.375 9.53 |

20.80 30.97 |

| 6 150 |

5S | 6.625 168.3 |

0.109 2.77 |

7.59 11.31 |

| 6 150 |

10S | 6.625 168.3 |

0.134 3.40 |

9.30 13.83 |

| 6 150 |

40S | 6.625 168.3 |

0.280 7.11 |

18.99 28.26 |

| 6 150 |

80S | 6.625 168.3 |

0.432 10.97 |

28.60 42.56 |

| (DN1) | (d1) | (s1) | (s1) | (s1) | (DN2) | (d2) | (s2) | (s2) | (s2) | (a) | (b) |

| 15 | 21.3 | 2.0 | 3.2 | 4.0 | 15 | 21.3 | 2.0 | 3.2 | 4.0 | 25 | 25 |

| 10 | 17.2 | 1.8 | 2.9 | - | 25 | 25 | |||||

| 20 | 26.9 | 2.3 | 3.2 | 4.0 | 20 | 26.9 | 2.3 | 3.2 | 4.0 | 29 | 29 |

| 15 | 21.3 | 2.0 | 3.2 | 4.0 | 29 | 29 | |||||

| 10 | 17.2 | 1.8 | 2.9 | - | 29 | 29 | |||||

| 25 | 33.7 | 2.6 | 3.2 | 4.0 | 25 | 33.7 | 2.6 | 3.2 | 4.0 | 38 | 38 |

| 20 | 26.9 | 2.3 | 3.2 | 4.0 | 38 | 38 | |||||

| 15 | 21.3 | 2.0 | 3.2 | 4.0 | 38 | 38 | |||||

| 32 | 42.4 | 2.6 | 3.6 | 4.0 | 32 | 42.4 | 2.6 | 3.6 | 4.0 | 48 | 48 |

| 25 | 33.7 | 2.6 | 3.2 | 4.0 | 48 | 48 | |||||

| 20 | 26.9 | 2.3 | 3.2 | 4.0 | 48 | 48 | |||||

| 15 | 21.3 | 2.0 | 3.2 | 4.0 | 48 | 48 | |||||

| 40 | 48.3 | 2.6 | 4.0 | 5.0 | 40 | 48.3 | 2.6 | 4.0 | 5.0 | 57 | 57 |

| 32 | 42.4 | 2.6 | 3.6 | 4.0 | 57 | 57 | |||||

| 25 | 33.7 | 2.6 | 3.2 | 4.0 | 57 | 57 | |||||

| 20 | 26.9 | 2.3 | 3.2 | 4.0 | 57 | 57 | |||||

| 50 | 60.3 | 2.9 | 4.5 | 5.6 | 50 | 60.3 | 2.9 | 4.5 | 5.6 | 64 | 64 |

| 40 | 48.3 | 2.6 | 4.0 | 5.0 | 64 | 60 | |||||

| 32 | 42.4 | 2.6 | 3.6 | 4.0 | 64 | 57 | |||||

| 25 | 33.7 | 2.6 | 3.2 | 4.0 | 64 | 51 | |||||

| 20 | 26.9 | 2.3 | 3.2 | 4.0 | 64 | 44 | |||||

| 65 | 76.1 | 2.9 | 5.0 | 7.1 | 65 | 76.1 | 2.9 | 5.0 | 7.1 | 76 | 76 |

| 50 | 60.3 | 2.9 | 4.5 | 5.6 | 76 | 70 | |||||

| 40 | 48.3 | 2.6 | 4.0 | 5.0 | 76 | 67 | |||||

| 32 | 42.4 | 2.6 | 3.6 | 4.0 | 76 | 64 | |||||

| 25 | 33.7 | 2.6 | 3.2 | 4.0 | 76 | 57 | |||||

| 80 | 88.9 | 3.2 | 5.6 | 8.0 | 80 | 88.9 | 3.2 | 5.6 | 8.0 | 86 | 86 |

| 65 | 76.1 | 2.9 | 5.0 | 7.1 | 86 | 83 | |||||

| 50 | 60.3 | 2.9 | 4.5 | 5.6 | 86 | 76 | |||||

| 40 | 48.3 | 2.6 | 4.0 | 5.0 | 86 | 73 | |||||

| 32 | 42.4 | 2.6 | 3.6 | 4.0 | 86 | 70 | |||||

| 100 | 114.3 | 3.6 | 6.3 | 8.8 | 100 | 114.3 | 3.6 | 6.3 | 8.8 | 105 | 105 |

| 80 | 88.9 | 3.2 | 5.6 | 8.0 | 105 | 98 | |||||

| 65 | 76.1 | 2.9 | 5.0 | 7.1 | 105 | 95 | |||||

| 50 | 60.3 | 2.9 | 4.5 | 5.6 | 105 | 89 | |||||

| 40 | 48.3 | 2.6 | 4.0 | 5.0 | 105 | 86 | |||||

| 125 | 139.7 | 4.0 | 6.3 | 10.0 | 125 | 139.7 | 4.0 | 6.3 | 10.0 | 124 | 124 |

| 100 | 114.3 | 3.6 | 6.3 | 8.8 | 124 | 117 | |||||

| 80 | 88.9 | 3.2 | 5.6 | 8.0 | 124 | 111 | |||||

| 65 | 76.1 | 2.9 | 5.0 | 7.1 | 124 | 108 | |||||

| 50 | 60.3 | 2.9 | 4.5 | 5.6 | 124 | 105 | |||||

| 150 | 168.3 | 4.5 | 7.1 | 11.0 | 150 | 168.3 | 4.5 | 7.1 | 11.0 | 143 | 143 |

| 125 | 139.7 | 4.0 | 6.3 | 10.0 | 143 | 137 | |||||

| 100 | 114.3 | 3.6 | 6.3 | 8.8 | 143 | 130 | |||||

| 80 | 88.9 | 3.2 | 5.6 | 8.0 | 143 | 124 | |||||

| 65 | 76.1 | 2.9 | 5.0 | 7.1 | 143 | 121 | |||||

| 200 | 219.1 | 6.3 | 8.0 | 12.5 | 200 | 219.1 | 6.3 | 8.0 | 12.5 | 178 | 178 |

| 150 | 168.3 | 4.5 | 7.1 | 11.0 | 178 | 168 | |||||

| 125 | 139.7 | 4.0 | 6.3 | 10.0 | 178 | 162 | |||||

| 100 | 114.3 | 3.6 | 6.3 | 8.8 | 178 | 156 | |||||

| 80 | 88.9 | 3.2 | 5.6 | 8.0 | 178 | 152 | |||||

| 250 | 273.0 | 6.3 | 8.8 | 14.2 | 250 | 273.0 | 6.3 | 8.8 | 14.2 | 216 | 216 |

| 200 | 219.1 | 6.3 | 8.0 | 12.5 | 216 | 203 | |||||

| 150 | 168.3 | 4.5 | 7.1 | 11.0 | 216 | 194 | |||||

| 125 | 139.7 | 4.0 | 6.3 | 10.0 | 216 | 191 | |||||

| 100 | 114.3 | 3.6 | 6.3 | 8.8 | 216 | 184 | |||||

| 300 | 323.9 | 7.1 | 10.0 | 16.0 | 300 | 323.9 | 7.1 | 10.0 | 16.0 | 254 | 254 |

| 250 | 273.0 | 6.3 | 8.8 | 14.2 | 254 | 241 | |||||

| 200 | 219.1 | 6.3 | 8.0 | 12.5 | 254 | 229 | |||||

| 150 | 168.3 | 4.5 | 7.1 | 11.0 | 254 | 219 | |||||

| 125 | 139.7 | 4.0 | 6.3 | 10.0 | 254 | 216 |