| Specifications Chart | ASME B16.9 Fittings |

|---|---|

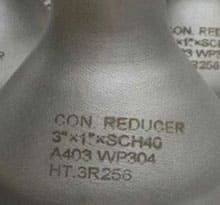

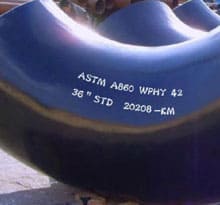

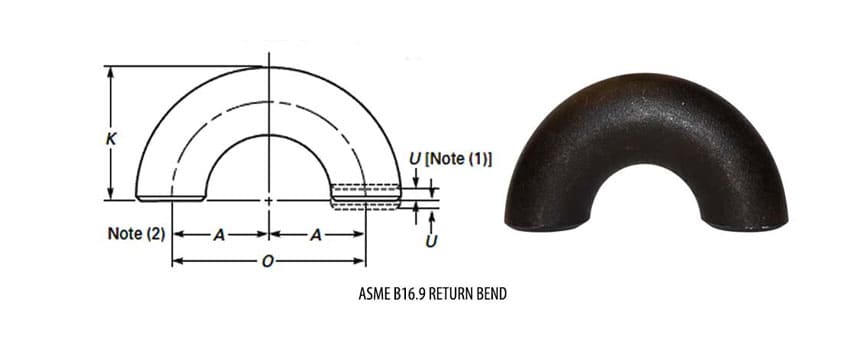

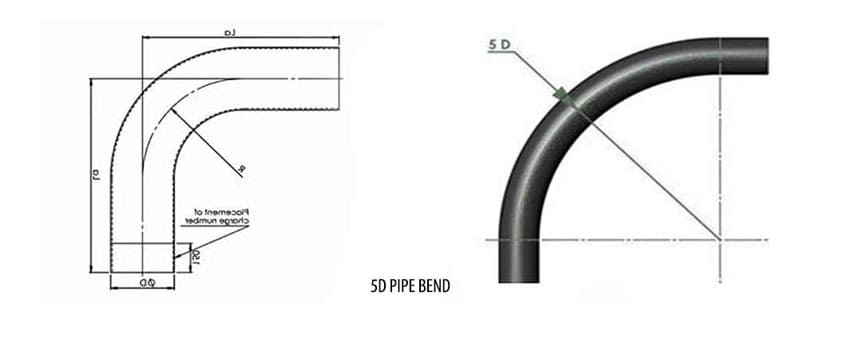

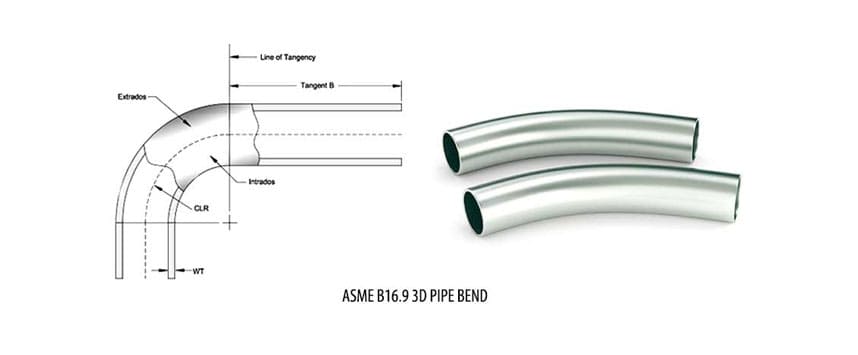

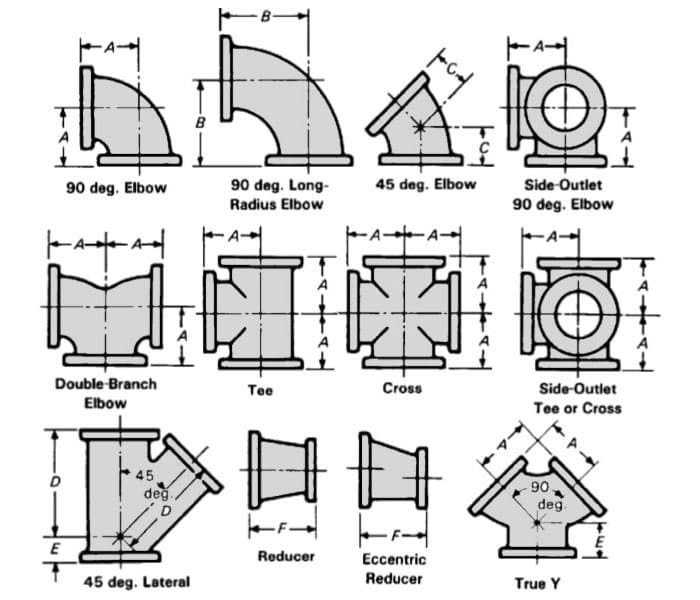

| Manufacturer Types Of ASME B16.9 | Elbow (45/ 90/ 180 Degree/ Long Radius And Short Radius) Tee (Reducing, Equal, Unequal, Lateral, Straight, Barred, Split Tee) Reducer (Concentric And Eccentric) End Cap (Square, Round, Rectangular) Stub End (Long And Short) Pipe Bend ( 45 Degree And 90 Degree) . |

| Methods | ButtWeld Welded Seamless |

| Royal Steel Manufacturer Of This Pressure Class | Class 150 And Class 300 |

| Standard | ASME/ANSI B16.9, MSS-SP-43, EN 10253, DIN 2605-1, DIN 2617, EN 1092-1. |

| Available Thickness | SCH 5S To SCH XXS |

| Bending Radius | R=1D/ 2D/ 3D/ 5D/ 6D/ 8D/ 10D or Custom |

| Surface Treatment | Sand blasting/ Sand Rolling/ Sand Blasting |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Manufacturer Size | Buttweld ½" NB to 120" NB Seamless ½” to 24” Welded ½” to 120” Two Joint / Two Halve Fittings 6” to 48” |

| Our service | Nace Mr 01 75 Sour Service Impact Test As Per Ug 84 Macro Structure Analysis Hydrogen Induce Cracking Test (Hic) Sulphide Stress Cracking Test (Sscc) Cryogenic Services (Cryo),hydrogen Services (H2) Helieum Leak Test Dye Peniterant Test (Dp) Magnetic Partius Test (Mp) Post Weld Heat Treatment (Pwht) Ultrasonic Test (Ut) Hydro Test, Etc. |

| Coating | Anti-rust Paint/ Zinc Plated/ Oil Black Paint/ Yellow Transparent/ Cold and Hot Dip Galvanized |

| Supporting Material | Gasket/ Ring Joint/ Flange Bolts |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged/ Heat treated and machined |

| Normal Pipe Size | Daimeter Nominal | Outer Daimeter at Bevel | Center-Center (O) | Back-Face (K) | ||

|---|---|---|---|---|---|---|

| Long Radius | Short Radius | Long Radius | Short Radius | |||

| 1/2 | 15 | 21.3 | 76 | 48 | ||

| 1 | 25 | 33.4 | 76 | 51 | 56 | 41 |

| 1-1/4 | 32 | 42.2 | 95 | 64 | 70 | 52 |

| 1-1/2 | 40 | 48.3 | 114 | 76 | 83 | 62 |

| 2 | 50 | 60.3 | 152 | 102 | 106 | 81 |

| 2-1/2 | 65 | 73.0 | 190 | 127 | 132 | 100 |

| 3 | 80 | 88.9 | 229 | 152 | 159 | 121 |

| 3-1/2 | 90 | 101.6 | 267 | 178 | 184 | 140 |

| 4 | 100 | 114.3 | 305 | 203 | 210 | 159 |

| 5 | 125 | 141.3 | 381 | 254 | 262 | 197 |

| 6 | 150 | 168.3 | 457 | 305 | 313 | 237 |

| 8 | 200 | 219.1 | 610 | 406 | 414 | 313 |

| 10 | 250 | 273.0 | 762 | 508 | 518 | 391 |

| 12 | 300 | 323.8 | 914 | 610 | 619 | 467 |

| 14 | 350 | 355.6 | 1067 | 711 | 711 | 533 |

| 16 | 400 | 406.4 | 1219 | 813 | 813 | 610 |

| 18 | 450 | 457 | 1372 | 914 | 914 | 686 |

| 20 | 500 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 550 | 559 | 1676 | 1118 | 1118 | 838 |

| 24 | 600 | 610 | 1829 | 1219 | 1219 | 914 |

| Normal Pipe Size | Bevel Outer Daimeter | Center-End | |||

| (D) | (C) | (M) | |||

| Nominal Diameter | Inch | Ser. (B) | Ser. (A) | ||

| 20 | 3/4 | 25 | 26.9 | 29 | |

| 200 | 8 | 219 | 219.1 | 178 | |

| 25 | 1 | 32 | 33.7 | 38 | |

| 32 | 11/4 | 38 | 42.4 | 48 | |

| 150 | 6 | 159 | 168.3 | 143 | |

| 50 | 2 | 57 | 60.3 | 64 | |

| 65 | 21/2 | 76 | 76.1(73) | 76 | |

| 80 | 3 | 89 | 88.9 | 86 | |

| 450 | 18 | 478 | 457.2 | 343 | |

| 90 | 31/2 | ― | 101.6 | 95 | |

| 100 | 4 | 108 | 114.3 | 105 | |

| 500 | 20 | 529 | 508.0 | 381 | |

| 300 | 12 | 325 | 323.9 | 254 | |

| 400 | 16 | 426 | 406.4 | 305 | |

| 600 | 24 | 630 | 610 | 432 | |

| 700 | 28 | 720 | 711 | 521 | |

| 950 | 38 | ― | 965 | 711 | |

| 800 | 32 | 820 | 813 | 597 | |

| 850 | 34 | ― | 864 | 635 | |

| 1050 | 42 | ― | 1067 | 762 | 711 |

| 1200 | 48 | 1220 | 1220 | 889 | 838 |

| 1100 | 44 | 1120 | 1118 | 813 | 762 |

| Standard Of Pipes | Specification | . Bauart 5 | 2D/ 5D | |

|---|---|---|---|---|

| Size (DN) | Diameter | CLR | CLR | CLR |

| 20 | 26,9 | 110 | 67 | |

| 25 | 33,7 | 110 | 84 | |

| 32 | 42,4 | 110 | 106 | |

| 40 | 48,3 | 110 | 212 | |

| 50 | 60,3 | 125 | 151 | |

| 65 | 76,1 | 175 | 190 | |

| 80 | 88,9 | 205 | 222 | |

| 100 | 114,3 | 270 | 286 | |

| 125 | 139,7 | 330 | 350 | |

| 150 | 168,3 | 390 | 421 | |

| 200 | 219,1 | 510 | ||

| 250 | 273 | 650 | ||

| 300 | 323,9 | 775 | ||

| 350 | 355,6 | 850 | ||

| 400 | 406,4 | 970 | ||

| 500 | 508 | 1245 | ||

| NPS For (Normal Size Of Pipe) | O.D. For (Outside Dai.) | BW 90 Deg Elbow | BW 45 Deg Elbow | BW Return 180 Deg Elbow | ||||

|---|---|---|---|---|---|---|---|---|

| (In Inch) | BW (Long Radius) Elbow | BW (Short Radius) Elbow | BW (Long Radius) Elbow | BW (Short Radius) Elbow | ||||

| (MM) | (inch) | Center-Face (Inches) |

Center-Face (Inches) |

Center-Face (In Inches) |

Radius (In Inches) |

Center-Center (In Inches) |

Back-face (In Inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| NPS For (Normal Size Of Pipe) | O.D. For (Outside Dai.) | BW Pipe End Cap | BW Pipe Straight Tee | BW Pipe Straight Cross | Buttweld Stub Ends | |||

|---|---|---|---|---|---|---|---|---|

| (Inches) | (Millimeter) | (In Inches) | Length (In Inches) |

Center-End (In Inches) |

Center-End (In Inches) |

Lap Dia. (In Inches) |

Length (Long) (In Inches) |

Length (Short) (In Inches) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

|

NPS (Normal Size Of Steel Pipe) |

10S Sche |

40S Sche |

80S Sche |

||||||

|

ASME B16.9 Butt weld 90 Deg Elbow |

ASME B16.9 Butt weld 45 Deg Elbow | ASME B16.9 Butt weld Equal Tee |

ASME B16.9 Butt weld 90 Deg Elbows |

ASME B16.9 Butt weld 45 Deg Elbows |

ASME B16.9 Butt weld Equal Tee |

ASME B16.9 Butt weld 90 Deg Elbow | ASME B16.9 Butt weld 45 Deg Elbow |

ASME B16.9 Butt weld Equal Tee |

|

|

8 |

0.02 |

0.01 |

0.03 |

0.03 |

0.02 |

0.06 |

0.04 |

0.03 |

0.07 |

|

10 |

0.03 |

0.02 |

0.05 |

0.03 |

0.02 |

0.03 |

0.06 |

0.04 |

0.09 |

|

15 |

0.06 |

0.03 |

0.09 |

0.08 |

0.04 |

0.10 |

0.10 |

0.05 |

0.14 |

|

20 |

0.07 |

0.03 |

0.13 |

0.08 |

0.04 |

0.17 |

0.11 |

0.05 |

0.20 |

|

25 |

0.14 |

0.08 |

0.28 |

0.15 |

0.11 |

0.29 |

0.22 |

0.14 |

0.38 |

|

32 |

0.23 |

0.11 |

0.49 |

0.26 |

0.17 |

0.59 |

0.40 |

0.23 |

0.68 |

|

40 |

0.30 |

0.17 |

0.68 |

0.40 |

0.23 |

0.86 |

0.51 |

0.29 |

1.02 |

|

50 |

0.50 |

0.25 |

0.85 |

0.70 |

0.4 |

1.28 |

0.91 |

0.59 |

1.59 |

|

65 |

0.85 |

0.48 |

1.41 |

1.40 |

0.77 |

2.19 |

1.81 |

0.99 |

3.13 |

|

80 |

1.25 |

0.63 |

1.77 |

2.20 |

1.08 |

3.31 |

2.97 |

1.50 |

4.45 |

|

90 |

1.70 |

0.75 |

2.67 |

2.83 |

1.42 |

4.08 |

4.00 |

2.00 |

5.44 |

|

100 |

2.10 |

1.08 |

3.46 |

4.47 |

2.09 |

5.27 |

6.18 |

2.81 |

7.71 |

|

150 |

5.45 |

2.72 |

8.07 |

10.89 |

5.44 |

10.99 |

16.32 |

8.16 |

13.61 |

|

200 |

10.20 |

5.33 |

15.65 |

21.54 |

10.77 |

20.91 |

33.11 |

16.56 |

28.12 |

|

250 |

18.15 |

9.75 |

26.46 |

38.56 |

19.27 |

35.38 |

51.71 |

25.86 |

49.90 |

|

300 |

25.80 |

13.62 |

39.46 |

59.42 |

29.71 |

62.14 |

79.38 |

39.69 |

83.91 |

|

NPS For (Normal Size Of Steel Pipe) |

10S Sch |

40S Sch |

80S Sch |

||||||

| ANSI B16.9 Butt weld Con Reducer | ANSI B16.9 Butt weld Ecc Reducer | ANSI B16.9 Butt weld Reducing Or Unequal Tee | ANSI B16.9 Butt weld Con Reducer | ANSI B16.9 Butt weld Ecc Reducer | ANSI B16.9 Butt weld Reducing Or Unequal Tee | ANSI B16.9 Butt weld Con Reducer | ANSI B16.9 Butt weld Ecc Reducer | ANSI B16.9 Butt weld Reducing Or Unequal Tee | |

|

40x.25 |

0.19 |

0.19 |

0.60 |

0.26 |

0.26 |

0.76 |

0.34 |

0.34 |

0.90 |

|

50x25 |

0.28 |

0.28 |

0.73 |

0.40 |

0.40 |

1.10 |

0.54 |

0.54 |

1.37 |

|

50x40 |

0.31 |

0.31 |

0.76 |

0.45 |

0.45 |

1.15 |

0.59 |

0.59 |

1.43 |

|

80x.50 |

0.55 |

0.55 |

1.56 |

1.00 |

1.00 |

2.91 |

1.79 |

1.79 |

3.91 |

|

100x50 |

0.78 |

0.78 |

2.94 |

1.50 |

1.50 |

4.48 |

1.95 |

1.95 |

6.55 |

|

100x80 |

0.87 |

0.87 |

3.04 |

1.74 |

1.74 |

4.64 |

2.33 |

2.33 |

6.79 |

|

150x80 |

1.82 |

1.82 |

6.86 |

3.95 |

3.95 |

9.68 |

5.51 |

5.51 |

11.57 |

|

150x100 |

1.96 |

1.96 |

7.10 |

4.07 |

4.07 |

11.94 |

5.96 |

5.96 |

11.97 |

|

200x100 |

3.01 |

3.01 |

13.46 |

6.55 |

6.55 |

17.98 |

9.23 |

9.23 |

24.18 |

|

200x150 |

3.19 |

3.19 |

14.08 |

6.74 |

6.74 |

18.82 |

10.12 |

10.12 |

25.31 |

| Outside Daimeter (O.D.) & Inside Daimeter (I.D.) | List Of Equivalent | (NPS) | Size Of Threads In Inch |

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 |

0.540 |

1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

| 1-21/32 | 1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

| ASME B16.9 Pipe Fittings Tolerance | |||||||

| Common Type Of ASME B16.9 Fittings | 45 degree elbows And 90 deg elbows | 180 Deg Returns | |||||

| Normal Size Of Steel Pipe | O.D. at Bevel |

I.D. at End |

WT For (Wall Thickness) t / t1 |

Center-End Dai. A-B-C-M | Center-Center Dai. (O) |

Back-Face Dai. (K) |

Align-ment of Ends (U) |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | - | - | - | - |

| 32 a 48 | +7 -5 | 4,8 | 5 | - | - | - | - |

| Normal Size Of Pipe (DN) |

Schedule Number |

Outer Daimeter In inch millmeter |

Wall Thickness inch millmeter |

Mass lb/ft kg/m |

|---|---|---|---|---|

| 1/8 6 |

5S | 0.405 10.3 |

... | ... |

| 1/8 6 |

10S | 0.405 10.3 |

0.049 1.24 |

0.19 0.28 |

| 1/8 6 |

40S | 0.405 10.3 |

0.068 1.73 |

0.24 0.37 |

| 1/8 6 |

80S | 0.405 10.3 |

0.095 2.41 |

0.31 0.47 |

| 1/4 8 |

5S | 0.540 13.7 |

... | ... |

| 1/4 8 |

10S | 0.540 13.7 |

0.065 1.65 |

0.33 0.49 |

| 1/4 8 |

40S | 0.540 13.7 |

0.088 2.24 |

0.43 0.63 |

| 1/4 8 |

80S | 0.540 13.7 |

0.119 3.02 |

0.54 0.80 |

| 3/8 10 |

5S | 0.675 17.1 |

... | ... |

| 3/8 10 |

10S | 0.675 17.1 |

0.065 1.65 |

0.42 0.63 |

| 3/8 10 |

40S | 0.675 17.1 |

0.091 2.31 |

0.57 0.84 |

| 3/8 10 |

80S | 0.675 17.1 |

0.126 3.20 |

0.74 1.10 |

| 1/2 15 |

5S | 0.840 21.3 |

0.065 1.65 |

0.54 0.80 |

| 1/2 15 |

10S | 0.840 21.3 |

0.083 2.11 |

0.67 1.00 |

| 1/2 15 |

40S | 0.840 21.3 |

0.109 2.77 |

0.85 1.27 |

| 1/2 15 |

80S | 0.840 21.3 |

0.147 3.73 |

1.09 1.62 |

| 3/4 20 |

5S | 1.050 26.7 |

0.065 1.65 |

0.68 1.02 |

| 3/4 20 |

10S | 1.050 26.7 |

0.083 2.11 |

0.86 1.28 |

| 3/4 20 |

40S | 1.050 26.7 |

0.113 2.87 |

1.13 1.69 |

| 3/4 20 |

80S | 1.050 26.7 |

0.154 3.91 |

1.48 2.20 |

| 1 25 |

5S | 1.315 33.4 |

0.065 1.65 |

0.68 1.02 |

| 1 25 |

10S | 1.315 33.4 |

0.083 2.11 |

0.86 1.28 |

| 1 25 |

40S | 1.315 33.4 |

0.133 3.38 |

1.68 2.50 |

| 1 25 |

80S | 1.315 33.4 |

0.179 4.55 |

2.17 3.24 |

| 1-1/4 32 |

5S | 1.660 42.2 |

0.065 1.65 |

1.11 1.65 |

| 1-1/4 32 |

10S | 1.660 42.2 |

0.109 2.77 |

1.81 2.69 |

| 1-1/4 32 |

40S | 1.660 42.2 |

0.140 3.56 |

2.27 3.39 |

| 1-1/4 32 |

80S | 1.660 42.2 |

0.191 4.85 |

3.00 4.47 |

| 1-1/2 40 |

5S | 1.900 48.3 |

0.065 1.65 |

1.28 1.90 |

| 1-1/2 40 |

10S | 1.900 48.3 |

0.109 2.77 |

2.09 3.11 |

| 1-1/2 40 |

40S | 1.900 48.3 |

0.145 3.68 |

2.72 4.05 |

| 1-1/2 40 |

80S | 1.900 48.3 |

0.200 5.08 |

3.63 5.41 |

| 2 50 |

5S | 2.375 60.3 |

0.065 1.65 |

1.61 2.39 |

| 2 50 |

10S | 2.375 60.3 |

0.109 2.77 |

2.64 3.93 |

| 2 50 |

40S | 2.375 60.3 |

0.154 3.91 |

3.66 5.44 |

| 2 50 |

80S | 2.375 60.3 |

0.218 5.54 |

5.03 7.48 |

| 2-1/2 65 |

5S | 2.875 73 |

0.083 2.11 |

2.48 3.69 |

| 2-1/2 65 |

10S | 2.875 73 |

0.120 3.05 |

3.53 5.26 |

| 2-1/2 65 |

40S | 2.875 73 |

0.203 5.16 |

5.80 8.63 |

| 2-1/2 65 |

80S | 2.875 73 |

0.276 7.01 |

7.67 11.41 |

| 3 80 |

5S | 3.500 88.9 |

0.083 2.11 |

3.03 4.52 |

| 3 80 |

10S | 3.500 88.9 |

0.120 3.05 |

4.34 6.46 |

| 3 80 |

40S | 3.500 88.9 |

0.216 5.49 |

7.58 11.29 |

| 3 80 |

80S | 3.500 88.9 |

0.300 7.62 |

10.26 15.27 |

| 3-1/2 90 |

5S | 4.000 101.6 |

0.083 2.11 |

3.48 5.18 |

| 3-1/2 90 |

10S | 4.000 101.6 |

0.120 3.05 |

4.98 7.41 |

| 3-1/2 90 |

40S | 4.000 101.6 |

0.226 5.74 |

9.12 13.57 |

| 3-1/2 90 |

80S | 4.000 101.6 |

0.318 8.08 |

12.52 18.64 |

| 4 100 |

5S | 4.500 114.3 |

0.083 2.11 |

3.92 5.84 |

| 4 100 |

10S | 4.500 114.3 |

0.120 3.05 |

5.62 8.37 |

| 4 100 |

40S | 4.500 114.3 |

0.237 6.02 |

10.80 16.08 |

| 4 100 |

80S | 4.500 114.3 |

0.337 8.56 |

15.00 22.32 |

| 5 125 |

5S | 5.563 141.3 |

0.109 2.77 |

6.36 9.46 |

| 5 125 |

10S | 5.563 141.3 |

0.134 3.40 |

7.78 11.56 |

| 5 125 |

40S | 5.563 141.3 |

0.258 6.55 |

14.63 21.77 |

| 5 125 |

80S | 5.563 141.3 |

0.375 9.53 |

20.80 30.97 |

| 6 150 |

5S | 6.625 168.3 |

0.109 2.77 |

7.59 11.31 |

| 6 150 |

10S | 6.625 168.3 |

0.134 3.40 |

9.30 13.83 |

| 6 150 |

40S | 6.625 168.3 |

0.280 7.11 |

18.99 28.26 |

| 6 150 |

80S | 6.625 168.3 |

0.432 10.97 |

28.60 42.56 |

| Normal Size Of Steel Pipe | Outer Daimeter | Ave. Inner Daimeter |

(Min.) Wall Thickness |

Fittings Weight In KG | (Max.) Working Pressure |

|---|---|---|---|---|---|

| 1/4" | .540 | .344 | .088 | .086 | 780 |

| 3/8" | .675 | .473 | .091 | .115 | 620 |

| 1/2" | .840 | .602 | .109 | .170 | 590 |

| 3/4" | 1.050 | .804 | .113 | .226 | 480 |

| 1" | 1.315 | 1.029 | .133 | .333 | 450 |

| *1-1/4" | 1.660 | 1.360 | .140 | .450 | 370 |

| *1-1/2" | 1.900 | 1.590 | .145 | .537 | 330 |

| *2" | 2.375 | 2.047 | .154 | .720 | 280 |

| 2-1/2" | 2.875 | 2.445 | .203 | 1.136 | 300 |

| *3" | 3.500 | 3.042 | .216 | 1.488 | 260 |

| 3-1/2" | 4.000 | 3.521 | .226 | 1.789 | 240 |

| *4" | 4.500 | 3.998 | .237 | 2.118 | 220 |

| 5" | 5.563 | 5.016 | .258 | 2.874 | 190 |

| *6" | 6.625 | 6.031 | .280 | 3.733 | 180 |

| *8" | 8.625 | 7.942 | .322 | 5.619 | 160 |

| *10" | 10.750 | 9.976 | .365 | 7.966 | 140 |

| *12" | 12.750 | 11.889 | .406 | 10.534 | 130 |

| *14" | 14.000 | 13.073 | .437 | 12.462 | 130 |

| *16" | 16.000 | 14.940 | .500 | 16.286 | 130 |

| Normal Size Of Steel Pipe | (Outer Diameter) | Available (Inner Diameter) |

(Man.) Wall Thickness |

Fittings Weight In Kg | (Max.) Working Pressure |

|---|---|---|---|---|---|

| 1/4" | .540 | .282 | .119 | .105 | 1130 |

| 3/8" | .675 | .403 | .126 | .146 | 920 |

| 1/2" | .840 | .526 | .147 | .213 | 850 |

| 3/4" | 1.050 | .722 | .154 | .289 | 690 |

| 1" | 1.315 | .936 | .179 | .424 | 630 |

| 1-1/4" | 1.660 | 1.255 | .191 | .586 | 520 |

| 1-1/2" | 1.900 | 1.476 | .200 | .711 | 470 |

| 2" | 2.375 | 1.913 | .218 | .984 | 400 |

| 2-1/2" | 2.875 | 2.290 | .276 | 1.500 | 420 |

| 3" | 3.500 | 2.864 | .300 | 2.010 | 370 |

| 3-1/2" | 4.000 | 3.326 | .318 | 2.452 | 350 |

| 4" | 4.500 | 3.786 | .337 | 2.938 | 320 |

| 5" | 5.563 | 4.768 | .375 | 4.078 | 290 |

| 6" | 6.625 | 5.709 | .432 | 5.610 | 280 |

| 8" | 8.625 | 7.565 | .500 | 8.522 | 250 |

| 10" | 10.750 | 9.493 | .593 | 12.635 | 230 |

| 12" | 12.750 | 11.294 | .687 | 17.384 | 230 |

| 14" | 14.000 | 12.410 | .750 | 20.852 | 220 |

| 16" | 16.000 | 14.213 | .843 | 26.810 | 220 |

| ASME B16.9 Pressure Ratings | |||||

|---|---|---|---|---|---|

| ASME B16.9 Fittings Temperature Ratings | Types Of Pressure Ratings Class | ||||

| Class 150# | Class 300# | ||||

| 1/4 - 1 (Inch) | 1 1/4 - 2 (Inch) | 2 1/2 - 3 (Inch) | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |