ASTM A105 is a standard specification for carbon steel forgings for piping applications. The A105 specification covers a range of carbon steel forgings that are intended for use in pressure systems involving high-temperature and ambient-temperature services. The material specified under A105 is well-suited for various applications, including flanges, fittings, valves, and other components used in piping systems.

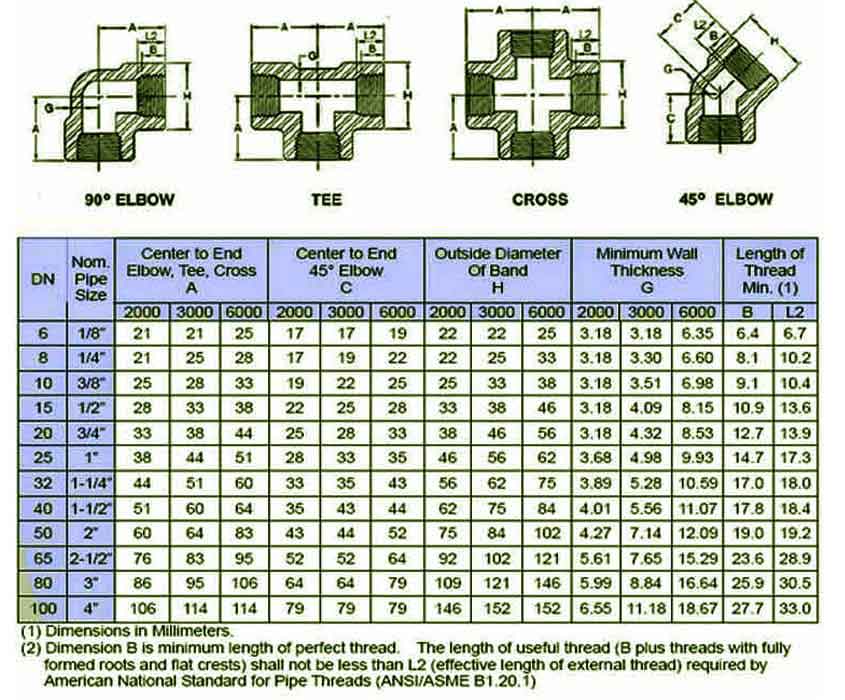

Elbow: Used for changing the direction of a pipeline.

Tee: Used to create branches in a piping system, forming a T-shape.

Cross: Similar to a tee but with an additional outlet to create a cross shape.

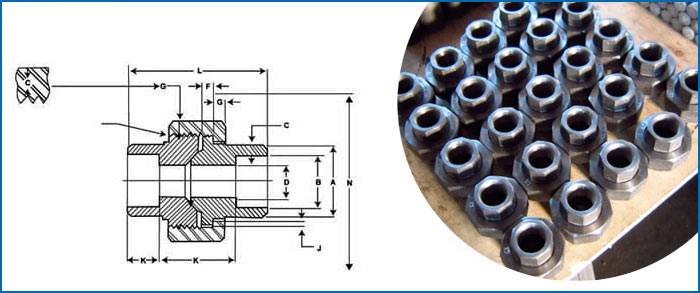

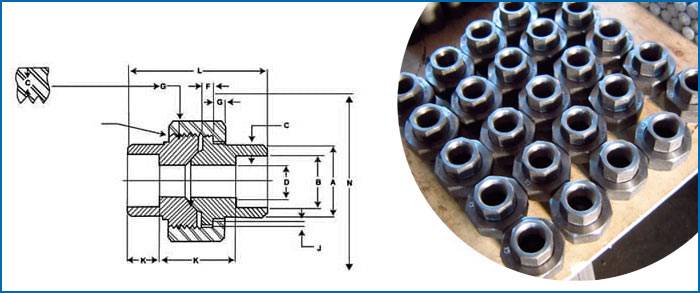

Coupling: Used to connect two pipes of the same diameter.

Union: A threaded coupling with a nut that allows for easy disassembly of pipes.

Bushings: Used to reduce the size of a threaded opening.

Cap: Used to close the end of a pipe.

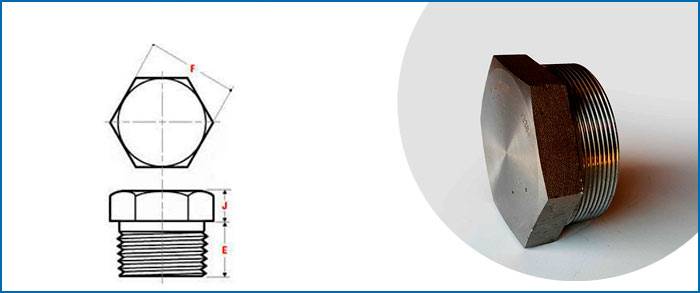

Plug: Similar to a cap but designed for threaded openings.

It's crucial to follow industry standards and specifications, including proper heat treatment procedures, when using ASTM A105 forged fittings. Additionally, installation should adhere to best practices to ensure the integrity and safety of the piping system. Regular inspection and maintenance are also important for the continued performance of the fittings in service.

| Diameter Range : | DN6-DN100 |

|---|---|

| Pressure Rate : | 3000 LB / 6000LB/ 9000LB |

| End Connection : | Threaded / Socket Weld |

| Forging : | 1,700 deg F and 2,200 deg F |

| Tensile : | 70 KSI, min |

| Thread Types : | NPT/ BSPP/ BSPT |

| Hardness : | 187 HBW max |

| Heat Treatment : | 950°C |

| Advantages : | Strong and highly durable Affordability Flexibility Corrosion resistant Environmentally friendly |

| Element | Composition %, Note C |

|---|---|

| Carbon | .35 maximum |

| Sulfur | .040 maximum |

| Silicon | .10-35 |

| Manganese | .60-1.05 |

| Chromium | .30 maximum, note A,B |

| Molybdenum | .12 maximum, note A,B |

| Vanadium | .08 maximum, note A |

| Phosphorus | .035 maximum |

| Copper | .40 maximum, note A |

| Nickel | .40 maximum, note A |

| Tensile | 70 ksi, (minimum) |

| Yield, note A | 36 ksi, (minimum) |

| Hardness | 187 HBW (maximum) |

| Elongation in 2in, Basic min. for wall 5/16″ and over, strip test | 30% |

| Temperature (°C) | Maximum Working Pressure (Bar) |

|---|---|

| Minus 20° to 40° C | 20 |

| 100° | 16.5 |

| 150° | 15 |

| 200° | 14 |

| 220° | 13.5 |

| Description Of ASTM A105 Forged Fittings Size | Class Designation | ||

|---|---|---|---|

| Class 3000 | Class 6000 | Class 9000 | |

| Elbow (45 degree and 90 degree) ASME B16.11 Tee/ ASME B16.11 Cross/ (ASME B16.11 Full Coupling And Half Coupling) ASME B16.11 End Cap |

½ - 4 Inches | ½ - 2 Inches | ½ - 2 Inches |

| ½ - 4 Inches | ½ - 2 Inches | ½ - 2 Inches | |

| ½ - 4 Inches | ½ - 2 Inches | ½ - 2 Inches | |

| Standard | System Name |

|---|---|

| British Standard Pipe | (BSP) |

| British Standard Pipe Parallel Thread | (BSPP) |

| British Standard Pipe Taper Thread | (BSPT) |

| National Pipe Thread | (NPT) |

| National Pipe Thread Fuel | (NPTF) |

| NPS | 90 Deg Elbow | Tee | Half Coupling | Cap | ||||

| Class 3000 | Class 6000 | 3000# | 6000# | Class 3000 | 6000 LBS | 3000# | Class 6000 | |

| 3/8 | 0.09 | 0.14 | 0.12 | 0.20 | 0.05 | 0.08 | 0.05 | 0.08 |

| 1/2 | 0.15 | 0.22 | 0.20 | 0.31 | 0.09 | 0.13 | 0.09 | 0.13 |

| 3/4 | 0.24 | 0.36 | 0.33 | 0.50 | 0.14 | 0.21 | 0.14 | 0.21 |

| 1 | 0.38 | 0.57 | 0.53 | 0.80 | 0.22 | 0.34 | 0.22 | 0.34 |

| 11/4 | 0.60 | 0.91 | 0.84 | 1.27 | 0.36 | 0.54 | 0.36 | 0.54 |

| 11/2 | 0.96 | 1.44 | 1.35 | 2.02 | 0.57 | 0.86 | 0.57 | 0.86 |

| 2 | 1.54 | 2.31 | 2.16 | 3.23 | 0.92 | 1.38 | 0.92 | 1.38 |

| 21/2 | 2.46 | 3.44 | ||||||

| 3 | 3.93 | 5.50 | ||||||

Threaded

| NPS | 90 degree elbow | threaded tee | half coupling | end cap | ||||

| Class 2000 | Class 3000 | Class 6000 | 2000 LBS | 3000 LBS | 3000 LBS | 6000 LBS | 3000# | |

| 3/8 | 0.07 | 0.12 | 0.18 | 0.09 | 0.16 | 0.03 | 0.09 | 0.03 |

| 1/2 | 0.12 | 0.19 | 0.28 | 0.16 | 0.26 | 0.07 | 0.16 | 0.07 |

| 3/4 | 0.19 | 0.30 | 0.45 | 0.26 | 0.42 | 0.10 | 0.22 | 0.10 |

| 1 | 0.31 | 0.48 | 0.72 | 0.43 | 0.67 | 0.21 | 0.44 | 0.21 |

| 11/4 | 0.50 | 0.76 | 1.14 | 0.70 | 1.06 | 0.36 | 0.52 | 0.36 |

| 11/2 | 0.79 | 1.21 | 1.81 | 1.10 | 1.69 | 0.52 | 0.95 | 0.52 |

| 2 | 1.27 | 1.93 | 2.89 | 1.77 | 2.70 | 0.69 | 1.40 | 0.69 |

| 21/2 | 2.03 | 3.08 | 4.62 | 2.84 | 4.31 | 1.15 | 2.00 | 1.15 |

| 3 | 3.24 | 4.92 | 7.38 | 4.53 | 6.88 | 1.60 | 3.00 | 1.60 |

| (NPS) | Bore Of Socket Weld | Depth Of Socket Weld | Diameter Of Bore |

| (B) | (J) | (D) | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

|

NPS

|

Outer Daimeter |

Wall Thickness |

Bore Of Socket Weld |

Water Way Bore |

Socket Weld Depth |

Length Assem Nominal |

|||

|

(D) minimum

|

(C) minimum

|

(D1)

|

(D2)

|

(J) minimum

|

(L)

|

||||

|

(DN)

|

Normal Pipe Size

|

Socket |

Threaded

|

Socket

|

Threaded

|

Socket

|

Socket And Threaded |

Socket

|

Socket And Threaded

|

|

6

|

1/8

|

21.8

|

14.7

|

3.2

|

2.5

|

10.65

|

6.43

|

10

|

41.4

|

|

8

|

1/4

|

21.8

|

19.0

|

3.3

|

3.1

|

14.10

|

9.45

|

10

|

41.4

|

|

10

|

3/8

|

25.9

|

22.9

|

3.5

|

3.2

|

17.55

|

13.51

|

10

|

46.0

|

|

15

|

1/2

|

31.2

|

27.7

|

4.1

|

3.8

|

21.70

|

17.07

|

10

|

49.0

|

|

20

|

3/4

|

37.1

|

33.5

|

4.3

|

4.0

|

27.05

|

21.39

|

13

|

56.9

|

|

25

|

1

|

45.5

|

41.4

|

5.0

|

4.6

|

33.80

|

27.74

|

13

|

62.0

|

|

32

|

11/4

|

54.9

|

50.5

|

5.3

|

4.9

|

42.55

|

35.36

|

13

|

71.1

|

|

40

|

11/2

|

61.5

|

57.2

|

5.6

|

5.1

|

48.65

|

41.20

|

13 |

76.5

|

|

50

|

2

|

75.2

|

70.1

|

6.1

|

5.6

|

61.10

|

52.12

|

16

|

86.1

|

|

65

|

21/2

|

91.7

|

85.3

|

7.7

|

7.1

|

73.80

|

64.31

|

16

|

102.4

|

|

80

|

3

|

109.2

|

102.4

|

8.4

|

7.7

|

89.80

|

77.27

|

16

|

109.0

|

| NPS (inch) |

TPI | Length of Threaded (inch) | Tap Drill In (inch) |

|||

|---|---|---|---|---|---|---|

| 1/16" | 27 | 0.313 | ||||

| 1/8" | 27 | 3/8 | 10 | 1/4 | 0.405 | R |

| 1/4" | 18 | 5/8 | 11 | 3/8 | 0.540 | 7/16 |

| 3/8" | 18 | 5/8 | 11 | 3/8 | 0.675 | 37/64 |

| 1/2" | 14 | 3/4 | 10 | 7/16 | 0.840 | 23/32 |

| 3/4" | 14 | 3/4 | 10 | 1/2 | 1.050 | 59/64 |

| 1" | 11-1/2 | 7/8 | 10 | 9/16 | 1.315 | 1-5/32 |

| 1-1/4" | 11-1/2 | 1 | 11 | 9/16 | 1.660 | 1-1/2 |

| 1-1/2" | 11-1/2 | 1 | 11 | 9/16 | 1.900 | 1-47/64 |

| 2" | 11-1/2 | 1 | 11 | 5/8 | 2.375 | 2-7/32 |

| 2-1/2" | 8 | 1 1/2 | 12 | 7/8 | 2.875 | 2-5/8 |

| 3" | 8 | 1 1/2 | 12 | 1 | 3.500 | 3-1/4 |

| 3-1/2" | 8 | 1 5/8 | 13 | 1 1/16 | 4.000 | 3-3/4 |

| 4" | 8 | 1 5/8 | 13 | 1 1/16 | 4.500 | 4-1/4 |

| 4 1/2" | 8 | 5.000 | 4-3/4 | |||

| 5" | 8 | 1 3/4 | 14 | 1 3/16 | 5.563 | 5-9/32 |

| 6" | 8 | 1 3/4 | 14 | 1 3/16 | 6.625 | 6-11/32 |

| 8" | 8 | 1 7/8 | 15 | 1 5/16 | 8.625 | |

| 10" | 8 | 2 | 16 | 1 1/2 | 10.750 | |

| 12" | 8 | 2 1/8 | 17 | 1 5/8 | 12.750 | |

| 14" | 8 | 14.000 | ||||

| 16" | 8 | 16.000 | ||||

| (NPS) | End to End | Outer Diameter | Thread Length (Min.) | |

| (A) | (D) | (B) | (J) | |

| 1/2 | 48 | 28 | 10.9 | 13.6 |

| 3/4 | 51 | 35 | 12.7 | 13.9 |

| 1 | 60 | 44 | 14.7 | 17.3 |

| 1.1/4 | 67 | 57 | 17 | 18 |

| 1.1/2 | 79 | 64 | 17.8 | 18.4 |

| 2 | 86 | 76 | 19 | 19.2 |

| 2.1/2 | 92 | 92 | 23.6 | 28.9 |

| 3 | 108 | 108 | 25.9 | 30.5 |

| 4 | 121 | 140 | 27.7 | 33 |

| Class | Connection | Pipe Equivalent | |

|---|---|---|---|

| SCH Number | Wall Designation | ||

| Class 2000 | NPT (Threaded ) | SCH 80 | XS |

| Class 3000 | NPT (Threaded ) | SCH 160 | – |

| Class 6000 | NPT (Threaded ) | – | XXS |

| 3000 LB | SW (Socket Weld) | SCH 80 | XS |

| 6000 LB | SW (Socket Weld ) | SCH 160 | – |

| 9000 LB | SW (Socket Weld) | – | XXS |