| Normal Pipe Size | (O.D.) For Outer Dia. |

Min. (WT) (T) |

Diameter Of (RF) (R) |

Bolt Hole No. | Holes Dia. | B.C. |

(SORF) Bore (I.D.) (SO.B) |

(WNRF) Bore (I.D.) (WN.B) |

Dia. Of Hub Base (H.B.) |

Dia. of Hub Top (H.T.) |

Slip On Length (S.L.) |

Weld Neck Length (W.L.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

| Stainless steels | |

|---|---|

| X2CrNi18-9 | W.Nr. 1.4307 |

| X2CrNiMo17-12-2 | W.Nr. 1.4406 |

| X2CrNiMo17-13-2 | W.Nr. 1.4404 |

| X2CrNiMoN22-5-3 | W.Nr. 1.4462 |

| X2CrNiMo17-13-3 | W.Nr. 1.4429 |

| X2CrNiMo25-7-4 | W.Nr. 1.4410 |

| X3CrNiMo13-4 | W.Nr. 1.4313 |

| X3CrNiMoN17-13-3 | W.Nr. 1.4436 |

| X6CrNiMoTi17-12-2 | W.Nr. 1.4571 |

| X6CrNiNb18-10 | W.Nr. 1.4550 |

| X5CrNi18-10 | W.Nr. 1.4301 |

| X5CrNiMo17-12-2 | W.Nr. 1.4401 |

| X6CrNi18-11 | W.Nr. 1.4948 |

| Nickel steels | |

|---|---|

| 12Ni14 | EN 10222-3 |

| W.Nr. 1.5680 | |

| Carbon steel forging | |

|---|---|

| C22 | EN 10250-2 |

| 20Mn5 | - |

| 20Mn5N | - |

| 20Mn5V | - |

| S235JRG2 | W.Nr. 1.0038 |

| S235J2G3 | W.Nr. 1.0116 |

| Alloy special steel | |

|---|---|

| 20MnMoNi4-5 | EN 10250-3 |

| Carbon steel for piping components | ||

|---|---|---|

| A105 And A105M | ASTM A105 | |

| Alloy steel forgings for pressure/ high temperature |

|---|

| A336 F1 |

| A336 F5 |

| A336 F5A |

| A336 F11 |

| A336 F22 |

| A336 F22V |

| A336 F9 |

| A336 F91 |

| A336 F92 |

| C22.8 | P250GH | A105 | SA105 | - | - |

| 15Mo3 | 16Mo3 | - | - | - | - |

| 13CrMo44 | 13CrMo4-5 | A182F12 | SA182F12 | - | - |

| 10CrMo910 | 11CrMo9-10 | A182F22 | SA182F22 | - | - |

| 1.4901 | - | A182F92 | SA182F92 | - | X10CrWMoVNb9-2 |

| 1.4903 | - | A182F91 | SA182F91 | - | X10CrMoVNb9-1 |

| 1.4905 | E911 | - | - | - | X11CrMoVWNb9-11 |

| 1.4910 | - | - | - | - | X6CrNiMoN17-12-2 |

| 1.4922 | - | - | - | - | X20CrMoV11-1 |

| 1.4923 | - | - | - | - | X22CrMoV12-1 |

| 1.4948 | - | - | - | - | X6CNi18-10 |

| 1.4981 | - | - | - | - | X8CrNiMoNb16-6 |

| 1.4988 | - | - | - | - | X8CrNiMoVNb16-13 |

| 1.6311 | - | - | - | - | 20MnMoNi45 |

| 1.6368 | - | WB36 | - | - | 15NiCuMoNb5 |

| W/TSTE355 | P355 | A350LF2 | SA350LF2 | - | - |

| W/TSTE420 | P420 | - | - | - | - |

| W/TSTE460 | - | - | - | - | - |

| 12CrMo19.5 (V/G) | - | A182/ F5 | SA182/ F5 | - | - |

| 1.5637 | - | - | - | - | 12Ni14 |

| 1.7715 | - | - | - | - | 14MoV63 |

| ST 52.3 | S355J2 N | - | - | - | - |

| 42CrMo4 | - | - | - | - | - |

| 25CrMo4 | - | - | - | - | - |

| 14MoV63 | - | - | - | - | - |

| 10Ni14 / 12Ni14 | - | - | - | - | - |

| 1.4021 | - | - | - | - | X20Cr13 |

| 1.4057 | - | - | - | - | X17CrNi16 2 |

| 1.4122 | - | - | - | - | X39CrMo17 1 |

| 1.4301 | - | A182/A479 304 | SA182/SA479 304L | - | X5CrNi18 10 |

| 1.4305 | - | - | - | - | X8CrNiS18 9 |

| 1.4306 | - | A182/A479 304 | SA182/SA479 304L | - | X2CrNi19 11 |

| 1.4307 | - | - | - | - | X2CrNi18 9 |

| 1.4313 | - | - | - | - | X3CrNiMo13 4 |

| 1.4401 | - | - | - | - | X5CrNiMo17 12 2 |

| 1.4404 | - | A182/A479 316 | SA182/SA479 316L | - | X2CrNiMo17 12 2 |

| 1.4410 | - | A182/A479 F53 | SA182/SA479 F53 | S 32750 | X2CrNiMoN25 7 4 |

| 1.4435 | - | - | - | S 31603 | X2CrNiMo18 14 3 |

| 1.4439 | - | - | - | S 31726 | X2CrNiMoN17 13 5 |

| 1.4462 | - | A182/A479 F51 | SA182/SA479 F51 | S 31803 | X2CrNiMoN22 5 3 |

| 1.4501 | - | A182/A479 F55 | SA182/SA479 F55 | S 32760 | X2CrNiMoCuWN25 7 4 |

| 1.4529 | - | - | - | - | X1NiCrMoCuN25 20 |

| 1.4539 | - | - | - | - | X1NiCrMoCu25 20 5 |

| 1.4541 | - | A182/A479 321 | SA182/SA479 321 | - | X6CrNiTi18 10 |

| 1.4550 | - | A182/A479 347 | SA182/SA479 347 | - | X6CrNiNb18 10 |

| 1.4571 | - | A182/A479 316Ti | SA182/SA479 316TI | - | X6CrNiMoTi17 12 2 |

| 1.4713 | - | - | - | - | X10CrAlSi7 |

| 1.4742 | - | - | - | - | X10CrAlSi25 |

| 1.4828 | - | - | - | - | X15CrNiSi20 12 |

| 1.4876 H/HT | - | Alloy 800 H/HT | - | - | X10NiCrAlTi32 20 |

| 1.4841 | - | A182/A479 F321H | - | - | X15CrNiSi25 21 |

| 1.4878 | - | - | - | - | X8CrNiTi18 10 |

| 2.4360 | - | Alloy 400 | - | - | NiCu30Fe |

| 2.4605 | - | Alloy 59 | - | - | NiCr23Mo16Al |

| 2.4610 | - | Hastelloy C4 | - | - | NiMo16Cr16Ti |

| 2.4617 | - | Alloy B2 | - | - | NiMo28 |

| 2.4660 | - | Alloy 20 | - | - | NiCr20CuMo |

| 2.4663 | - | Alloy 617 | - | - | NiFe30Cr29Mo |

| 2.4816 | - | Alloy 600 | - | - | NiCr15Fe |

| 2.4819 | - | Hastelloy C276 | - | - | NiMo16Cr15W |

| 2.4856 | - | Alloy 625 | - | - | NiCr22Mo9Nb |

| 3.7035 | - | Titan Grade2 | - | - | Ti2 |

| (Nominal Size Of Steel Pipe) | Outer Diameter (O.D.) | Min. (WT) |

RF Dia. Of (R) | Bolts Holes Number | Flanges Hole Dia. | Bolt Circle As Per ASME B16.5 | Slip On (SO) Bore I.D. | * WN (Weld Neck) Bore I.D. | Hub Base Diameter | Hub Top Diameter | SO (Slip On) Length | WN (Weld Neck) Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 9.50 | 1.50 | 5.00 | 8 | 1.00 | 7.50 | 3.57 | * | 5.00 | 3.50 | 2.12 | 4.00 |

| 4 | 11.50 | 1.75 | 6.19 | 8 | 1.25 | 9.25 | 4.57 | * | 6.25 | 4.50 | 2.75 | 4.50 |

| 5 | 13.75 | 2.00 | 7.31 | 8 | 1.38 | 11.00 | 5.66 | * | 7.50 | 5.56 | 3.12 | 5.00 |

| 6 | 15.00 | 2.19 | 8.50 | 12 | 1.25 | 12.50 | 6.72 | * | 9.25 | 6.63 | 3.38 | 5.50 |

| 8 | 18.50 | 2.50 | 10.63 | 12 | 1.50 | 15.50 | 8.72 | * | 11.75 | 8.63 | 4.00 | 6.38 |

| 10 | 21.50 | 2.75 | 12.75 | 16 | 1.50 | 18.50 | 10.88 | * | 14.50 | 10.75 | 4.25 | 7.25 |

| 12 | 24.00 | 3.12 | 15.00 | 20 | 1.50 | 21.00 | 12.88 | * | 16.50 | 12.75 | 4.63 | 7.88 |

| 14 | 25.25 | 3.38 | 16.25 | 20 | 1.63 | 22.00 | 14.14 | * | 17.75 | 14.00 | 5.12 | 8.38 |

| 16 | 27.75 | 3.50 | 18.50 | 20 | 1.75 | 24.25 | 16.16 | * | 20.00 | 16.00 | 5.25 | 8.50 |

| 18 | 31.00 | 4.00 | 21.00 | 20 | 2.00 | 27.00 | 18.18 | * | 22.25 | 18.00 | 6.00 | 9.00 |

| 20 | 33.75 | 4.25 | 23.00 | 20 | 2.13 | 29.50 | 20.20 | * | 24.50 | 20.00 | 6.25 | 9.75 |

| 24 | 41.00 | 5.50 | 27.25 | 20 | 2.63 | 35.50 | 24.25 | * | 29.50 | 24.00 | 8.00 | 11.50 |

| (Nominal Size Of Steel Pipe) | Outer Diameter (O.D.) | Min. (WT) |

RF Dia. Of (R) | Bolts Holes Number | Flanges Hole Dia. | Bolt Circle As Per ASME B16.5 | So Bore I.D. Of (SB) |

Hub Base Diameter | Hub Top Diameter | SO (Slip On) Length | WN (Weld Neck) Length | * WN Bore Inside Daimeter (WB) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1⁄2 | 4.75 | 0.88 | 1.38 | 4 | 0.88 | 3.25 | 0.88 | 1.50 | 0.84 | 1.25 | 2.38 | * |

| 3⁄4 | 5.12 | 1.00 | 1.69 | 4 | 0.88 | 3.50 | 1.09 | 1.75 | 1.05 | 1.38 | 2.75 | * |

| 1 | 5.88 | 1.12 | 2.00 | 4 | 1.00 | 4.00 | 1.36 | 2.06 | 1.32 | 1.62 | 2.88 | * |

| 11⁄4 | 6.25 | 1.12 | 2.50 | 4 | 1.00 | 4.38 | 1.70 | 2.50 | 1.66 | 1.62 | 2.88 | * |

| 11⁄2 | 7.00 | 1.25 | 2.88 | 4 | 1.12 | 4.88 | 1.95 | 2.75 | 1.90 | 1.75 | 3.25 | * |

| 2 | 8.50 | 1.50 | 3.63 | 8 | 1.00 | 6.50 | 2.44 | 4.12 | 2.38 | 2.25 | 4.00 | * |

| 21⁄2 | 9.62 | 1.62 | 4.13 | 8 | 1.12 | 7.50 | 2.94 | 4.88 | 2.88 | 2.50 | 4.12 | * |

| 3 | 10.50 | 1.88 | 5.00 | 8 | 1.25 | 8.00 | - | 5.25 | 3.50 | - | 4.62 | * |

| 4 | 12.25 | 2.12 | 6.19 | 8 | 1.38 | 9.50 | - | 6.38 | 4.50 | - | 4.88 | * |

| 5 | 14.75 | 2.88 | 7.31 | 8 | 1.63 | 11.50 | - | 7.75 | 5.56 | - | 6.12 | * |

| 6 | 15.50 | 3.25 | 8.50 | 12 | 1.50 | 12.50 | - | 9.00 | 6.63 | - | 6.75 | * |

| 8 | 19.00 | 3.62 | 10.63 | 12 | 1.75 | 15.50 | - | 11.50 | 8.63 | - | 8.38 | * |

| 10 | 23.00 | 4.25 | 12.75 | 12 | 2.00 | 19.00 | - | 14.50 | 10.75 | - | 10.00 | * |

| 12 | 26.50 | 4.88 | 15.00 | 16 | 2.12 | 22.50 | - | 17.75 | 12.75 | - | 11.12 | * |

| 14 | 29.50 | 5.25 | 16.25 | 16 | 2.38 | 25.00 | - | 19.50 | 14.00 | - | 11.75 | * |

| 16 | 32.50 | 5.75 | 18.50 | 16 | 2.63 | 27.75 | - | 21.75 | 16.00 | - | 12.25 | * |

| 18 | 36.00 | 6.38 | 21.00 | 16 | 2.88 | 30.50 | - | 23.50 | 18.00 | - | 12.88 | * |

| 20 | 38.75 | 7.00 | 23.00 | 16 | 3.12 | 32.75 | - | 25.25 | 20.00 | - | 14.00 | * |

| 24 | 46.00 | 8.00 | 27.25 | 16 | 3.63 | 39.00 | - | 30.00 | 24.00 | - | 16.00 | * |

| (Nominal Size Of Steel Pipe) | Outer Diameter (O.D.) | Min. (WT) |

RF Dia. Of (R) | Bolts Holes Number | Flanges Hole Dia. | Bolt Circle As Per ASME B16.5 | Hub Base Diameter | Hub Top Diameter | SO (Slip On) Length | WN (Weld Neck) Length | * WN (Weld Neck) Bore I.D. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1⁄2 | 5.25 | 1.19 | 1.38 | 4 | 0.88 | 3.50 | 1.69 | 0.84 | 1.56 | 2.88 | * |

| 3⁄4 | 5.50 | 1.25 | 1.69 | 4 | 0.88 | 3.75 | 2.00 | 1.05 | 1.69 | 3.12 | * |

| 1 | 6.25 | 1.38 | 2.00 | 4 | 1.00 | 4.25 | 2.25 | 1.32 | 1.88 | 3.50 | * |

| 11⁄4 | 7.25 | 1.50 | 2.50 | 4 | 1.12 | 5.13 | 2.88 | 1.66 | 2.06 | 3.75 | * |

| 11⁄2 | 8.00 | 1.75 | 2.88 | 4 | 1.25 | 5.75 | 3.12 | 1.90 | 2.38 | 4.38 | * |

| 2 | 9.25 | 2.00 | 3.63 | 8 | 1.12 | 6.75 | 3.75 | 2.38 | 2.75 | 5.00 | * |

| 21⁄2 | 10.50 | 2.25 | 4.13 | 8 | 1.25 | 7.75 | 4.50 | 2.88 | 3.12 | 5.62 | * |

| 3 | 12.00 | 2.62 | 5.00 | 8 | 1.38 | 9.00 | 5.25 | 3.50 | – | 6.62 | * |

| 4 | 14.00 | 3.00 | 6.19 | 8 | 1.63 | 10.75 | 6.50 | 4.50 | – | 7.50 | * |

| 5 | 16.50 | 3.62 | 7.31 | 8 | 1.88 | 12.75 | 8.00 | 5.56 | – | 9.00 | * |

| 6 | 19.00 | 4.25 | 8.50 | 8 | 2.12 | 14.50 | 9.25 | 6.63 | – | 10.75 | * |

| 8 | 21.75 | 5.00 | 10.63 | 12 | 2.12 | 17.25 | 12.00 | 8.63 | – | 12.50 | * |

| 10 | 26.50 | 6.50 | 12.75 | 12 | 2.63 | 21.25 | 14.75 | 10.75 | – | 16.50 | * |

| 12 | 30.00 | 7.25 | 15.00 | 12 | 2.88 | 24.38 | 17.38 | 12.75 | – | 18.25 | * |

| Temperature (in F°) | ASME/ ANSI B16.5 Class 300 Flanges |

| 100 | 740 |

| 200 | 680 |

| 300 | 655 |

| 400 | 635 |

| 500 | 605 |

| 600 | 570 |

| 650 | 550 |

| 700 | 530 |

| 750 | 505 |

| 800 | 410 |

| 850 | 320 |

| 900 | 230 |

| 950 | 135 |

| 1000 | 85 |

|

Normal Pipe Size |

DN |

|---|---|

|

1/2 |

15 |

|

3/4 |

20 |

|

1 |

25 |

|

1 1/4 |

32 |

|

1 1/2 |

40 |

|

2 |

50 |

|

2 1/2 |

65 |

|

3 |

80 |

|

4 |

100 |

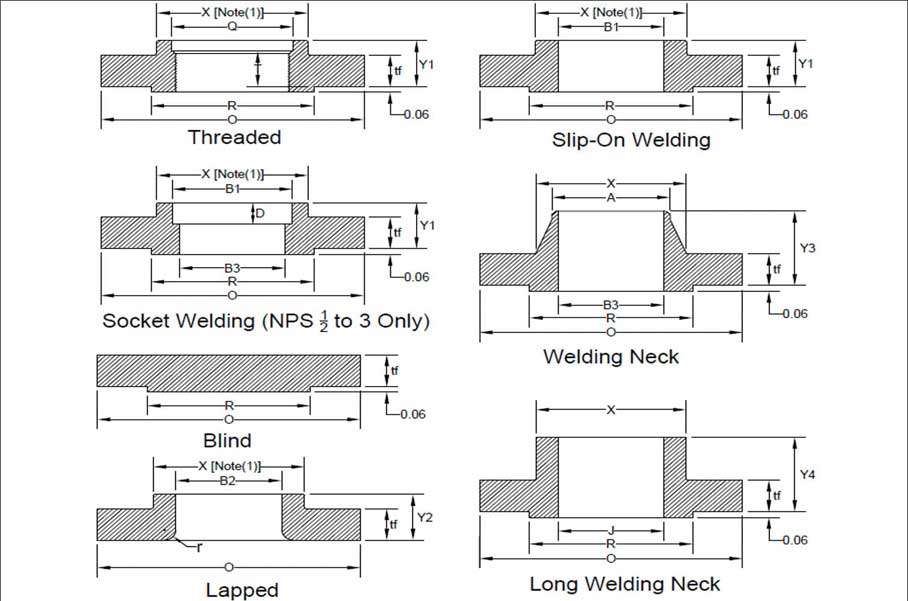

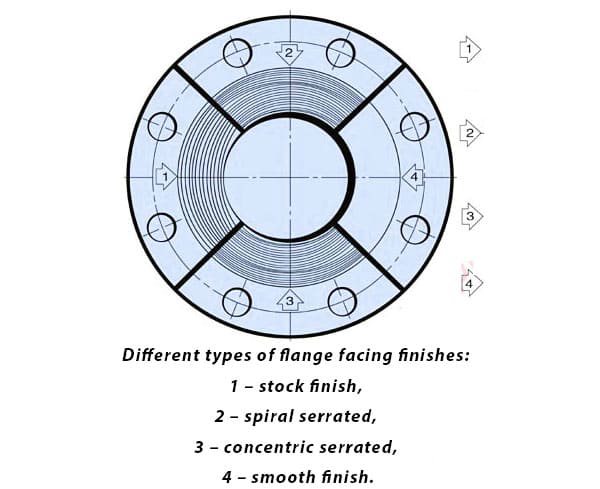

| Type Of ASME/ ANSI B16.5 Pipe Flange | Diameter | Tolerance Chart |

|---|---|---|

| (A) | (Outer Diameter) |

|

| (D) | (Inner Diameter) |

|

| (B) | Contact Face |

|

| (J) | Hub At Base Dai. |

|

| (H) | Diameter of hub at point of welding |

|

| (P) | Drilling |

|

| Eccentricity of (bc) with respect to facing |

|

|

| (C) | (W.T.) |

|

| (K) | hub Length |

|

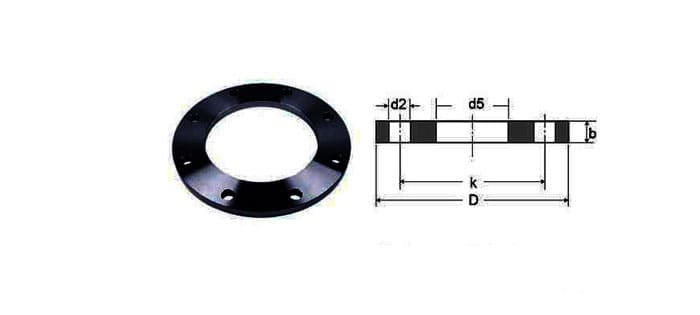

| Normal Size Of Pipe | Pipes Diameter | Inner Diameter | flanges holes Number | Diameter Of Flange | Wall Flange Thickness | B.C. Diameter | B. H. Diameter | Weight In Kilogram | |

| (DN) | (ISO) | (DIN) | (D5) | (BN) | (D) | (b) | (K) | (d2) | (Kilogram) |

| 10 | – | 14 | 14.5 | 4 | 90 | 16 | 60 | 14 | 0.7 |

| 17.2 | – | 17.7 | 4 | 90 | 16 | 60 | 14 | 0.69 | |

| 15 | – | 20 | 21 | 4 | 95 | 16 | 65 | 14 | 0.77 |

| 21.3 | – | 22 | 4 | 95 | 16 | 65 | 14 | 0.77 | |

| 20 | – | 25 | 26 | 4 | 105 | 18 | 75 | 14 | 1.06 |

| 26.9 | – | 27.6 | 4 | 105 | 18 | 75 | 14 | 1.05 | |

| 25 | – | 30 | 31 | 4 | 115 | 18 | 85 | 14 | 1.27 |

| 33.7 | – | 34.4 | 4 | 115 | 18 | 85 | 14 | 1.25 | |

| 32 | – | 38 | 39 | 4 | 140 | 18 | 100 | 18 | 1.86 |

| 42.4 | – | 43.1 | 4 | 140 | 18 | 100 | 18 | 1.83 | |

| 40 | – | 44.5 | 45.5 | 4 | 150 | 18 | 110 | 18 | 2.12 |

| 48.3 | – | 49 | 4 | 150 | 18 | 110 | 18 | 2.09 | |

| 50 | – | 57 | 58.1 | 4 | 165 | 20 | 125 | 18 | 2.78 |

| 60.3 | – | 61.1 | 4 | 165 | 20 | 125 | 18 | 2.74 | |

| 65 | 76.1 | – | 77.1 | 8 | 185 | 22 | 145 | 18 | 3.48 |

| 80 | 88.9 | – | 90.3 | 8 | 200 | 24 | 160 | 18 | 4.33 |

| 100 | – | 108 | 109.6 | 8 | 235 | 24 | 190 | 22 | 5.82 |

| 114.3 | – | 115.9 | 8 | 235 | 24 | 190 | 22 | 5.61 | |

| 125 | – | 133 | 134.8 | 8 | 270 | 26 | 220 | 26 | 7.91 |

| 139.7 | – | 141.6 | 8 | 270 | 26 | 220 | 26 | 7.6 | |

| 150 | – | 159 | 161.1 | 8 | 300 | 28 | 250 | 26 | 10.12 |

| 168.3 | – | 170.5 | 8 | 300 | 28 | 250 | 26 | 9.58 | |

| 175 | 193.7 | – | 196.1 | 12 | 350 | 32 | 295 | 30 | 14.45 |

| 200 | 219.1 | – | 221.8 | 12 | 375 | 34 | 320 | 30 | 16.9 |

| 250 | – | 267 | 270.2 | 12 | 450 | 38 | 385 | 33 | 27.28 |

| 273 | – | 276.2 | 12 | 450 | 38 | 385 | 33 | 26.51 | |

| 300 | 323.9 | – | 327.6 | 16 | 515 | 42 | 450 | 33 | 36.38 |

| 350 | 355.6 | – | 359.7 | 16 | 580 | 46 | 510 | 36 | 52.83 |

| – | 368 | 372.2 | 16 | 580 | 46 | 510 | 36 | 50.24 | |

| 400 | 406.4 | – | 411 | 16 | 660 | 50 | 585 | 39 | 74.71 |

| – | 419 | 423.7 | 16 | 660 | 50 | 585 | 39 | 71.44 | |

| 500 | 508 | – | 513.6 | 20 | 755 | 52 | 670 | 42 | 86.87 |

| Normal Pipe Size | (A) | (B) |

|---|---|---|

| 1/2 | 3.0 | 1.5 |

| 3/4 | 3.0 | 1.5 |

| 1 | 3.0 | 1.5 |

| 1-1/4 | 3.0 | 1.5 |

| 1-1/2 | 3.0 | 1.5 |

| 2 | 3.0 | 1.5 |

| 2-1/2 | 3.0 | 1.5 |

| 3 | 4.5 | 1.5 |

| 3-1/2 | 6.0 | 3.0 |

| 4 | 6.0 | 3.0 |

| 5 | 6.0 | 3.0 |

| 6 | 6.0 | 3.0 |

| 8 | 8.0 | 4.5 |

| 10 | 8.0 | 4.5 |

| 12 | 8.0 | 4.5 |

| 14 | 8.0 | 4.5 |

| 16 | 10.0 | 4.5 |

| 18 | 12.0 | 6.0 |

| 20 | 12.0 | 6.0 |

| 22 | 12.0 | 6.0 |

| 24 | 12.0 | 6.0 |

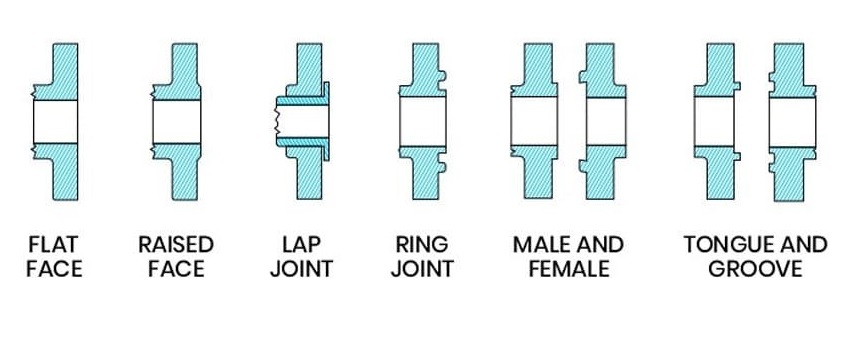

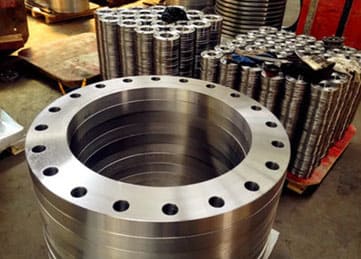

| Specification | ASME B16.5 Flange |

|---|---|

| Schedule | SCH 5S, SCH 10, SCH 40, SCH 80, SCH 120, SCH 160, SCH 180 To XXS |

| Dimensions And Standard | EN 1092-1/ EN 1092-2/ API |

| Manufacturer Length | NPS 1⁄₂" To NPS 48” |

| Face Type | RTJ/ FF/ RF/ lap joint/ Male & Female / Tongue & Groove. |

| Manufacturer Types | Reducing Flange Stainless Steel Weld Neck Flange Spades Ring Spacers Flanges Stainless Steel Blind Flange ASME B16.5 Square Flanges Orifice Flange Spectacle Blind Flanges Stainless Steel Slip On Flange Stainless Steel Plate Flange Nipo Flange Stainless Steel Lap Joint Flanges RTJ Flange |

| Forging Methods | Casting/ Forging/ Rolling/ Cutting |

| EN Standard | 6Bar/ 10Bar/ 16Bar/ 25Bar/ 40Bar |

| DIN Standard | PN6/ PN10/ PN16/ PN25/ PN40/ PN64 |

| JIS Standard | 5K/ 10K/ 16K 20K/ 30K/ 40K/ 63K |

| Other Standard | B16.47 Series A & B/ B16.48, BS4504/ GOST |

| UNI Standard | 6 Bar/ 10 Bar/ 16 Bar/ 25 Bar/ 40 Bar |

| Supporting Material | Gasket/ Ring Joint/ Flange Bolts |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged/ Heat treated and machined |

| Manufacturer of | Forged/ Threaded/ Screwed / Plate |

| Manufacturer Pressure Class | Class 150 (lb) up to 24" Class 300 (lb) up to 20" Class 600 (lb) up to 20" Class 900 (lb) up to 16" Class 1500 (lb) up to 10" Class 2500 (lb) up to 8" |

| Flange Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Flange Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

| Coating | Anti-rust Paint/ Zinc Plated/ Oil Black Paint/ Yellow Transparent/ Cold and Hot Dip Galvanized |

| Application | Bitumen upgraders Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

| Normal Size Of Steel Pipe | Dimensions In Millimeter | ASME B16.5 Flanges Weight In Kilogram | ||||

|---|---|---|---|---|---|---|

| Normal Size Of Steel Pipe In Inches | Size In Millimeter | ASME B16.5 Flanges Outer Daimeter (O.D.) In (MM) |

ANSI B16.5 Flanges Wall Thickness Of (D) (In M) |

(ANSI B16.5 Slip On Flanges) (ANSI B16.5 Socket Weld Flanges) |

(ANSI B16.5 Weld Neck Flanges) | (ANSI B16.5 Blind Flanges) |

| 1/2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| (Normal Size Of Steel Pipes) In Inch | (I.D.) Inner Daimeter Gasket |

(O.D.) Outer Daimeter Gasket | ||||

|---|---|---|---|---|---|---|

| Class 150#/ LB | Class 300#/ LB | Class 400#/ LB | Class 600#/ LB | Class 900#/ LB | ||

| 1/2 | 0.84 | 1.875 | 2.125 | 2.125 | 2.125 | 2.50 |

| 3/4 | 1.06 | 2.25 | 2.625 | 2.625 | 2.625 | 2.75 |

| 1 | 1.31 | 2.625 | 2.875 | 2.875 | 2.875 | 3.125 |

| 1 1/4 | 1.66 | 3 | 3.25 | 3.25 | 3.25 | 3.50 |

| 1 1/2 | 1.91 | 3.375 | 3.75 | 3.75 | 3.75 | 3.875 |

| 2 | 2.38 | 4.125 | 4.375 | 4.375 | 4.375 | 5.625 |

| 2 1/2 | 2.88 | 4.875 | 5.125 | 5.125 | 5.125 | 6.50 |

| 3 | 3.50 | 5.375 | 5.875 | 5.875 | 5.875 | 6.625 |

| 4 | 4.50 | 6.875 | 7.125 | 7.00 | 7.625 | 8.125 |

| 5 | 5.56 | 7.75 | 8.50 | 8.375 | 9.50 | 9.75 |

| 6 | 6.62 | 8.75 | 9.875 | 9.75 | 10.50 | 11.375 |

| 8 | 8.62 | 11 | 12.125 | 12.00 | 12.625 | 14.125 |

| 10 | 10.75 | 13.375 | 14.25 | 14.125 | 15.75 | 17.125 |

| 12 | 12.75 | 16.125 | 16.625 | 16.50 | 18.00 | 19.625 |

| Pipe Flange Size Inch | Pipe Flange Size MM | (Maximum) Radial Projection | |

|---|---|---|---|

| No Deeper Than the Bottom In Millimeter | Deeper Than the Bottom In Millimeter | ||

| 1/2 | 15 | 3.0 | 1.5 |

| 3/4 | 20 | 3.0 | 1.5 |

| 1 | 25 | 3.0 | 1.5 |

| 1 1/4 | 32 | 3.0 | 1.5 |

| 1 1/2 | 40 | 3.0 | 1.5 |

| 2 | 50 | 3.0 | 1.5 |

| 2 1/2 | 65 | 3.0 | 1.5 |

| 3 | 80 | 4.5 | 1.5 |

| 3 1/2 | 90 | 6.0 | 3.0 |

| 4 | 100 | 6.0 | 3.0 |

| 5 | 125 | 6.0 | 3.0 |

| 6 | 150 | 6.0 | 3.0 |

| 8 | 200 | 8.0 | 4.5 |

| 10 | 250 | 8.0 | 4.5 |

| 12 | 300 | 8.0 | 4.5 |

| 14 | 350 | 8.0 | 4.5 |

| 16 | 400 | 10.0 | 4.5 |

| 18 | 450 | 12.0 | 6.0 |

| Normal Size Of Steel Pipe | Outer Diameter (O.D.) | 10 Schedule | 20 Schedule | 30 Schedule | STD Wall | 40 Schedule | 60 Schedule | EXT Hvy | 80 Schedule | 100 Schedule | 120 Schedule | 140 Schedule | 160 Schedule | XX Hvy |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 0.84 | 0.083 | ... | ... | 0.109 | 0.109 | ... | 0.147 | 0.147 | ... | ... | ... | 0.188 | 0.294 |

| ¾ | 1.05 | 0.083 | ... | ... | 0.113 | 0.113 | ... | 0.154 | 0.154 | ... | ... | ... | 0.219 | 0.308 |

| 1 | 1.315 | 0.109 | ... | ... | 0.133 | 0.133 | ... | 0.179 | 0.179 | ... | ... | ... | 0.25 | 0.358 |

| 1 ¼ | 1.66 | 0.109 | ... | ... | 0.14 | 0.14 | ... | 0.191 | 0.191 | ... | ... | ... | 0.25 | 0.382 |

| 1 ½ | 1.9 | 0.109 | ... | ... | 0.145 | 0.145 | ... | 0.2 | 0.2 | ... | ... | ... | 0.281 | 0.4 |

| 2 | 2.375 | 0.109 | ... | ... | 0.154 | 0.154 | ... | 0.218 | 0.218 | ... | ... | ... | 0.344 | 0.436 |

| 2 ½ | 2.875 | 0.12 | ... | ... | 0.203 | 0.203 | ... | 0.276 | 0.276 | ... | ... | ... | 0.375 | 0.552 |

| 3 | 3.5 | 0.12 | - | - | 0.216 | 0.216 | - | 0.3 | 0.3 | - | - | - | 0.438 | 0.6 |

| 3 ½ | 4 | 0.12 | - | - | 0.226 | 0.226 | - | 0.318 | 0.318 | - | - | - | - | 0.636 |

| 4 | 4.5 | 0.12 | - | - | 0.237 | 0.237 | - | 0.337 | 0.337 | - | 0.438 | - | 0.531 | 0.674 |

| 5 | 5.563 | 0.134 | - | - | 0.258 | 0.258 | - | 0.375 | 0.375 | - | 0.5 | - | 0.625 | 0.75 |

| 6 | 6.625 | 0.134 | - | - | 0.28 | 0.28 | - | 0.432 | 0.432 | - | 0.562 | - | 0.719 | 0.864 |

| 8 | 8.625 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 |

| 10 | 10.75 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | 1 |

| 12 | 12.75 | 0.18 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | 1 |

| 14 | 14 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | - |

| 16 | 16 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | - |

| 18 | 18 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | - |

| 20 | 20 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | - |

| 22 | 22 | 0.25 | - | - | 0.375 | - | - | 0.5 | - | - | - | - | - | - |

| 24 | 24 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | - |

| 26 | 26 | - | - | - | 0.375 | - | - | 0.5 | - | - | - | - | - | - |

| 30 | 30 | 0.312 | 0.5 | 0.625 | 0.375 | - | - | 0.5 | - | - | - | - | - | - |