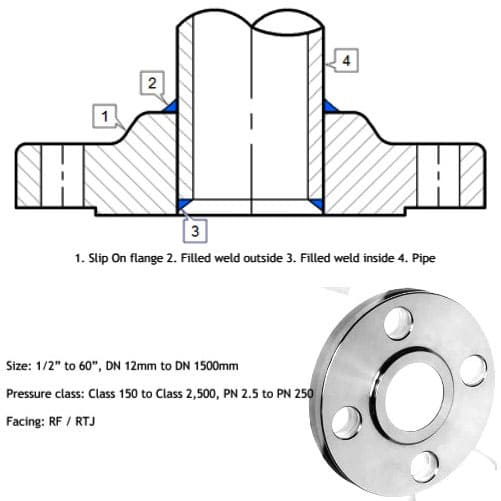

Stainless Steel Slip On Flange A stainless steel slip-on flange is a type of flange that is slipped over the end of a pipe and then welded in place. It has a circular bore and is designed to slide over the pipe, facilitating easy installation. The inner diameter of the flange matches the outer diameter of the pipe to which it is being connected. Slip-on flanges are commonly used in low-pressure and non-critical applications. What is a stainless steel flange used for? The Benefits and Uses of Stainless Steel Flanges | Texas Flange Stainless steel flanges are essential in industries like beverage, food, water, gas, and transport. It also provides several benefits, a few of these including: Corrosion and stain resistance: Stainless steel flanges are excellent in a wide range of atmospheric environments and many corrosive media.

| Specification | Stainless Steel Slip On Flange |

|---|---|

| Face Type | Slip On Raised Face Flanges Slip Blind Flanges Reducing Slip On Flanges Slip On Flat Face Flanges Slip Joint Flanges Slip On Plate Flanges |

| Making Methods | Casting And Forging Rolling And Cutting |

| Size | 1/2”, 2”, 3”, 4”, 6”, 8”, 10”, 12” to 24”. |

| Customized Diameter | Up to 40 Inches |

| Slip On Flange Use | Stainless Steel Slip On Flange are used in applications where the two pipes have to be held together with nuts and bolts. |

| Schedule | SCH 5S, SCH 10, SCH 40, SCH 80, SCH 120, SCH 160, SCH 180 To XXS |

| Manufacturer Length | NPS 1⁄₂" To NPS 48” |

| EN Standard | 6Bar/ 10Bar/ 16Bar/ 25Bar/ 40Bar |

| DIN Standard | PN6/ PN10/ PN16/ PN25/ PN40/ PN64 |

| JIS Standard | 5K/ 10K/ 16K 20K/ 30K/ 40K/ 63K |

| Other Standard | B16.47 Series A & B/ B16.48, BS4504/ GOST |

| UNI Standard | 6 Bar/ 10 Bar/ 16 Bar/ 25 Bar/ 40 Bar |

| Supporting Material | Gasket/ Ring Joint/ Flanges Bolts |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged/ Heat treated and machined |

| Manufacturer of | Forged/ Threaded/ Screwed / Plate |

| Manufacturer Pressure Class | Class 150 (lb) up to 24" Class 300 (lb) up to 20" Class 600 (lb) up to 20" Class 900 (lb) up to 16" Class 1500 (lb) up to 10" Class 2500 (lb) up to 8" |

| Flanges Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Flanges Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

| Coating | Anti-rust Paint/ Zinc Plated/ Oil Black Paint/ Yellow Transparent/ Cold and Hot Dip Galvanized |

| Application | Bitumen upgraders Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

|

Normal Sizes Of Steel Pipe In Inch

|

Class 150 RF Flanges

|

||||

|---|---|---|---|---|---|

|

Dia. Of

RF Flanges In (Inches) |

No. Of Raised Face

Bolts |

Dia. Of

Raised Face Bolts In (Inches) |

Dia. Of

Bolts Hole In (Inches) |

RF Bolts Circle

In (Inches) |

|

|

1/4

|

3-3/8

|

4

|

1/2

|

0.62

|

2-1/4

|

|

1/2

|

3-1/2

|

4

|

1/2

|

0.62

|

2-3/8

|

|

3/4

|

3-7/8

|

4

|

1/2

|

0.62

|

2-3/4

|

|

1

|

4-1/4

|

4

|

1/2

|

0.62

|

3-1/8

|

|

1-1/4

|

4-5/8

|

4

|

1/2

|

0.62

|

3-1/2

|

|

1-1/2

|

5

|

4

|

1/2

|

0.62

|

3-7/8

|

|

2

|

6

|

4

|

5/8

|

0.75

|

4-3/4

|

|

2-1/2

|

7

|

4

|

5/8

|

0.75

|

5-1/2

|

|

3

|

7-1/2

|

4

|

5/8

|

0.75

|

6

|

|

3-1/2

|

8-1/2

|

8

|

5/8

|

0.75

|

7

|

|

4

|

9

|

8

|

5/8

|

0.75

|

7-1/2

|

|

5

|

10

|

8

|

3/4

|

0.88

|

8-1/2

|

|

6

|

11

|

8

|

3/4

|

0.88

|

9-1/2

|

|

8

|

13-1/2

|

8

|

3/4

|

0.88

|

11-3/4

|

|

10

|

16

|

12

|

7/8

|

1

|

14-1/4

|

|

12

|

19

|

12

|

7/8

|

1

|

17

|

|

14

|

21

|

12

|

1

|

1.12

|

18-3/4

|

|

16

|

23-1/2

|

16

|

1

|

1.12

|

21-1/4

|

|

18

|

25

|

16

|

1-1/8

|

1.25

|

22-3/4

|

|

20

|

27-1/2

|

20

|

1-1/8

|

1.25

|

25

|

|

24

|

32

|

20

|

1-1/4

|

1.38

|

29-1/2

|

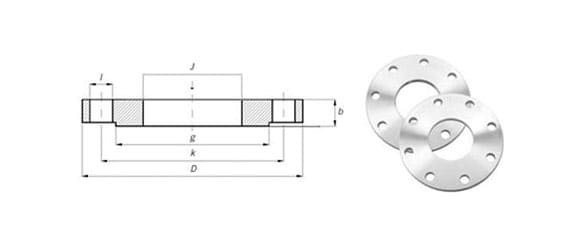

| Normal Size Of Steel Pipe | FF Dia. | Inner Daimeter | Flat Face Holes Number | Flat Face Flanges Daimeter | Wall Thickness (WT) | Daimeter of (B.C.) | Bolt Hole Daimeter | Weight in Kilogram (Kg) | |

| (DN) | (ISO) | (DIN) | (D5) | (BN) | (D) | (b) | (K) | (d2) | (Kilogram/PCS) |

| 10 | – | 14 | 14.5 | 4 | 90 | 16 | 60 | 14 | 0.7 |

| 17.2 | – | 17.7 | 4 | 90 | 16 | 60 | 14 | 0.69 | |

| 15 | – | 20 | 21 | 4 | 95 | 16 | 65 | 14 | 0.77 |

| 21.3 | – | 22 | 4 | 95 | 16 | 65 | 14 | 0.77 | |

| 20 | – | 25 | 26 | 4 | 105 | 18 | 75 | 14 | 1.06 |

| 26.9 | – | 27.6 | 4 | 105 | 18 | 75 | 14 | 1.05 | |

| 25 | – | 30 | 31 | 4 | 115 | 18 | 85 | 14 | 1.27 |

| 33.7 | – | 34.4 | 4 | 115 | 18 | 85 | 14 | 1.25 | |

| 32 | – | 38 | 39 | 4 | 140 | 18 | 100 | 18 | 1.86 |

| 42.4 | – | 43.1 | 4 | 140 | 18 | 100 | 18 | 1.83 | |

| 40 | – | 44.5 | 45.5 | 4 | 150 | 18 | 110 | 18 | 2.12 |

| 48.3 | – | 49 | 4 | 150 | 18 | 110 | 18 | 2.09 | |

| 50 | – | 57 | 58.1 | 4 | 165 | 20 | 125 | 18 | 2.78 |

| 60.3 | – | 61.1 | 4 | 165 | 20 | 125 | 18 | 2.74 | |

| 65 | 76.1 | – | 77.1 | 8 | 185 | 22 | 145 | 18 | 3.48 |

| 80 | 88.9 | – | 90.3 | 8 | 200 | 24 | 160 | 18 | 4.33 |

| 100 | – | 108 | 109.6 | 8 | 235 | 24 | 190 | 22 | 5.82 |

| 114.3 | – | 115.9 | 8 | 235 | 24 | 190 | 22 | 5.61 | |

| 125 | – | 133 | 134.8 | 8 | 270 | 26 | 220 | 26 | 7.91 |

| 139.7 | – | 141.6 | 8 | 270 | 26 | 220 | 26 | 7.6 | |

| 150 | – | 159 | 161.1 | 8 | 300 | 28 | 250 | 26 | 10.12 |

| 168.3 | – | 170.5 | 8 | 300 | 28 | 250 | 26 | 9.58 | |

| 175 | 193.7 | – | 196.1 | 12 | 350 | 32 | 295 | 30 | 14.45 |

| 200 | 219.1 | – | 221.8 | 12 | 375 | 34 | 320 | 30 | 16.9 |

| 250 | – | 267 | 270.2 | 12 | 450 | 38 | 385 | 33 | 27.28 |

| 273 | – | 276.2 | 12 | 450 | 38 | 385 | 33 | 26.51 | |

| 300 | 323.9 | – | 327.6 | 16 | 515 | 42 | 450 | 33 | 36.38 |

| 350 | 355.6 | – | 359.7 | 16 | 580 | 46 | 510 | 36 | 52.83 |

| – | 368 | 372.2 | 16 | 580 | 46 | 510 | 36 | 50.24 | |

| 400 | 406.4 | – | 411 | 16 | 660 | 50 | 585 | 39 | 74.71 |

| – | 419 | 423.7 | 16 | 660 | 50 | 585 | 39 | 71.44 | |

| 500 | 508 | – | 513.6 | 20 | 755 | 52 | 670 | 42 | 86.87 |

| 600 | 610 | – | 616.5 | 20 | 890 | 54 | 795 | 48 | 121.84 |

| 700 | 711 | – | 716 | 24 | 995 | 58 | 900 | 48 | 150.93 |

| 800 | 813 | – | 818 | 24 | 1140 | 64 | 1030 | 56 | 219.08 |

| 900 | 914 | – | 920 | 28 | 1250 | 70 | 1140 | 56 | 271.16 |

| 1000 | 1016 | – | 1022 | 28 | 1360 | 78 | 1250 | 56 | 344.95 |

| Normal Size Of Steel Pipe | Inner Diameter | Outer Daimeter | SORF Circle Bolt (B.C.) | Raised | Raised Face Of SORF | SORF Hight (H) | Wall Thickness Of (RF) Raised Face | (T1) | Thickness2 (Flat Face) |

SORF Bolts Holes |

Number Of SORF Flanges Bolt Hole |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 3.50 | 2.38 | 1.38 | .063 | 1.19 | .62 | .38 | .56 | .62 | 4 |

| 3/4 | 1.09 | 3.88 | 2.75 | 1.69 | .063 | 1.50 | .62 | .44 | .56 | .62 | 4 |

| 1 | 1.36 | 4.25 | 3.12 | 2.00 | .063 | 1.94 | .69 | .50 | .63 | .62 | 4 |

| 1-1/4 | 1.70 | 4.62 | 3.50 | 2.50 | .063 | 2.31 | .81 | .56 | .75 | .62 | 4 |

| 1-1/2 | 1.97 | 5.00 | 3.88 | 2.88 | .063 | 2.56 | .88 | .62 | .82 | .62 | 4 |

| 2 | 2.44 | 6.00 | 4.75 | 3.62 | .063 | 3.06 | 1.00 | .69 | .94 | .75 | 4 |

| 2-1/2 | 2.94 | 7.00 | 5.50 | 4.12 | .063 | 3.56 | 1.12 | .82 | 1.06 | .75 | 4 |

| 3 | 3.57 | 7.50 | 6.00 | 5.00 | .063 | 4.25 | 1.19 | .88 | 1.13 | .75 | 4 |

| 3-1/2 | 4.07 | 8.50 | 7.00 | 5.50 | .063 | 4.81 | 1.25 | .88 | 1.19 | .75 | 8 |

| 4 | 4.57 | 9.00 | 7.50 | 6.19 | .063 | 5.31 | 1.31 | .88 | 1.25 | .75 | 8 |

| 5 | 5.66 | 10.00 | 8.50 | 7.31 | .063 | 6.44 | 1.44 | .88 | 1.38 | .88 | 8 |

| 6 | 6.72 | 11.00 | 9.50 | 8.50 | .063 | 7.56 | 1.56 | .94 | 1.50 | .88 | 8 |

| 8 | 8.72 | 13.50 | 11.75 | 10.62 | .063 | 9.69 | 1.75 | 1.06 | 1.69 | .88 | 8 |

| 10 | 10.88 | 16.00 | 14.25 | 12.75 | .063 | 12.00 | 1.94 | 1.13 | 1.88 | 1.00 | 12 |

| 12 | 12.88 | 19.00 | 17.00 | 15.00 | .063 | 14.38 | 2.19 | 1.19 | 2.13 | 1.00 | 12 |

| 14 | 14.14 | 21.00 | 18.75 | 16.25 | .063 | 15.75 | 2.25 | 1.32 | 2.19 | 1.12 | 12 |

| 16 | 16.16 | 23.50 | 21.25 | 18.50 | .063 | 18.00 | 2.50 | 1.38 | 2.44 | 1.12 | 16 |

| 18 | 18.18 | 25.00 | 22.75 | 21.00 | .063 | 19.88 | 2.69 | 1.50 | 2.63 | 1.25 | 16 |

| 20 | 20.20 | 27.50 | 25.00 | 23.00 | .063 | 22.00 | 2.88 | 1.63 | 2.83 | 1.25 | 20 |

| 22 | 22.22 | 29.50 | 27.25 | 25.25 | .063 | 24.25 | 3.13 | 1.75 | 3.07 | 1.38 | 20 |

| 24 | 24.25 | 32.00 | 29.50 | 27.25 | .063 | 26.12 | 3.25 | 1.82 | 3.19 | 1.38 | 20 |

| Normal Size Of Steel Pipe | Inner Diameter | Outer Daimeter | SORF Circle Bolt (B.C.) | Raised | Raised Face Of SORF | SORF Hight (H) | Wall Thickness Of (RF) Raised Face | (T1) | Thickness2 (Flat Face) |

SORF Bolts Holes |

Number Of SORF Flanges Bolt Hole |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 3.75 | 2.62 | 1.38 | .063 | 1.50 | 0.88 | 0.50 | 0.82 | 0.62 | 4 |

| 3/4 | 1.09 | 4.62 | 3.25 | 1.69 | .063 | 1.88 | 1.00 | .056 | 0.94 | 0.75 | 4 |

| 1 | 1.36 | 4.88 | 3.50 | 2.00 | .063 | 2.12 | 1.06 | 0.63 | 1.00 | 0.75 | 4 |

| 1-1/4 | 1.70 | 5.25 | 3.88 | 2.50 | .063 | 2.50 | 1.06 | 0.69 | 1.00 | 0.75 | 4 |

| 1-1/2 | 1.95 | 6.12 | 4.50 | 2.88 | .063 | 2.75 | 1.19 | 0.75 | 1.13 | 0.88 | 4 |

| 2 | 2.44 | 6.50 | 5.00 | 3.62 | .063 | 3.31 | 1.31 | 0.82 | 1.25 | 0.75 | 8 |

| 2-1/2 | 2.94 | 7.50 | 5.88 | 4.12 | .063 | 3.94 | 1.50 | 0.94 | 1.44 | 0.88 | 8 |

| 3 | 3.57 | 8.25 | 6.62 | 5.00 | .063 | 4.62 | 1.69 | 1.06 | 1.63 | 0.88 | 8 |

| 3-1/2 | 4.07 | 9.00 | 7.25 | 5.50 | .063 | 5.25 | 1.75 | 1.13 | 1.69 | 0.88 | 8 |

| 4 | 4.57 | 10.00 | 7.88 | 6.19 | .063 | 5.75 | 1.88 | 1.19 | 1.82 | 0.88 | 8 |

| 5 | 5.66 | 11.00 | 9.25 | 7.31 | .063 | 7.00 | 2.00 | 1.32 | 1.94 | 0.88 | 8 |

| 6 | 6.72 | 12.50 | 10.62 | 8.50 | .063 | 8.12 | 2.06 | 1.38 | 2.00 | 0.88 | 12 |

| 8 | 8.72 | 15.00 | 13.00 | 10.62 | .063 | 10.25 | 2.44 | 1.56 | 2.38 | 1.00 | 12 |

| 10 | 10.88 | 17.50 | 15.25 | 12.75 | .063 | 12.62 | 2.62 | 1.82 | 2.56 | 1.12 | 16 |

| 12 | 12.88 | 20.50 | 17.75 | 15.00 | .063 | 14.75 | 2.88 | 1.94 | 2.82 | 1.25 | 16 |

| 14 | 14.14 | 23.00 | 20.25 | 16.25 | .063 | 16.75 | 3.00 | 2.06 | 2.94 | 1.25 | 20 |

| 16 | 16.16 | 25.50 | 22.50 | 18.50 | .063 | 19.00 | 3.25 | 2.19 | 3.19 | 1.38 | 20 |

| 18 | 18.18 | 28.00 | 24.75 | 21.00 | .063 | 21.00 | 3.50 | 2.32 | 3.44 | 1.38 | 24 |

| 20 | 20.20 | 30.50 | 27.00 | 23.00 | .063 | 23.12 | 3.75 | 2.44 | 3.69 | 1.38 | 24 |

| 22 | 22.22 | 33.00 | 29.25 | 25.25 | .063 | 25.25 | 4.00 | 2.57 | 3.94 | 1.63 | 24 |

| 24 | 24.25 | 36.00 | 32.00 | 27.25 | .063 | 27.62 | 4.19 | 2.69 | 4.13 | 1.62 | 24 |

| Normal Size Of Pipe | Inner Daimeter | Outer Daimeter | (SO) Circle Bolts | Raised (R) | Raised Face Of SO Flange | Hight (H) | Wall Thickness Of (Raised Face) |

(T1) | Flat Face (FF) (T2) |

SORF Bolts Holes | SO Flange Bolt Hole Number |

| 1/2 | 0.88 | 3.75 | 2.62 | 1.38 | .250 | 1.50 | 1.13 | 0.56 | 0.88 | 0.62 | 4 |

| 3/4 | 1.09 | 4.62 | 3.25 | 1.69 | .250 | 1.88 | 1.25 | 0.62 | 1.00 | 0.75 | 4 |

| 1 | 1.36 | 4.88 | 3.50 | 2.00 | .250 | 2.12 | 1.31 | 0.69 | 1.06 | 0.75 | 4 |

| 1-1/4 | 1.7 | 5.25 | 3.88 | 2.50 | .250 | 2.50 | 1.37 | 0.81 | 1.12 | 0.75 | 4 |

| 1-1/2 | 1.95 | 6.12 | 4.50 | 2.88 | .250 | 2.75 | 1.50 | 0.88 | 1.25 | 0.88 | 4 |

| 2 | 2.44 | 6.50 | 5.00 | 3.62 | .250 | 3.31 | 1.69 | 1.00 | 1.44 | 0.75 | 8 |

| 2-1/2 | 2.94 | 7.50 | 5.88 | 4.12 | .250 | 3.94 | 1.87 | 1.12 | 1.62 | 0.88 | 8 |

| 3 | 3.57 | 8.25 | 6.62 | 5.00 | .250 | 4.62 | 2.06 | 1.25 | 1.81 | 0.88 | 8 |

| 3-1/2 | 4.07 | 9.00 | 7.25 | 5.50 | .250 | 5.25 | 2.19 | 1.38 | 1.94 | 1.00 | 8 |

| 4 | 4.57 | 10.75 | 8.50 | 6.19 | .250 | 6.00 | 2.37 | 1.5 | 2.12 | 1.00 | 8 |

| 5 | 5.66 | 13.00 | 10.50 | 7.31 | .250 | 7.44 | 2.63 | 1.75 | 2.38 | 1.12 | 8 |

| 6 | 6.72 | 14.00 | 11.50 | 8.50 | .250 | 8.75 | 2.87 | 1.88 | 2.62 | 1.12 | 12 |

| 8 | 8.72 | 16.50 | 13.75 | 10.62 | .250 | 10.75 | 3.25 | 2.19 | 3.00 | 1.25 | 12 |

| 10 | 10.88 | 20.00 | 17.00 | 12.75 | .250 | 13.5 | 3.63 | 2.50 | 3.38 | 1.38 | 16 |

| 12 | 12.88 | 22.00 | 19.25 | 15.00 | .250 | 15.75 | 3.87 | 2.62 | 3.62 | 1.38 | 20 |

| 14 | 14.14 | 23.75 | 20.75 | 16.25 | .250 | 17.00 | 3.94 | 2.75 | 3.69 | 1.50 | 20 |

| 16 | 16.16 | 27.00 | 23.75 | 18.50 | .250 | 19.50 | 4.44 | 3.00 | 4.19 | 1.62 | 20 |

| 18 | 18.18 | 29.25 | 25.75 | 21.00 | .250 | 21.50 | 4.87 | 3.25 | 4.62 | 1.75 | 20 |

| 20 | 20.20 | 32.00 | 28.50 | 23.00 | .250 | 24.00 | 5.25 | 3.50 | 5.00 | 1.75 | 24 |

| 22 | 22.22 | 34.25 | 30.63 | 25.25 | .250 | 26.25 | 5.50 | 3.75 | 5.25 | 1.75 | 24 |

| 24 | 24.25 | 37.00 | 33.00 | 27.25 | .250 | 28.25 | 5.75 | 4.00 | 5.50 | 2.00 | 24 |

| Normal Size Of Pipe | Inner Daimeter | Outer Daimeter | (SO) Circle Bolts | Raised (R) | Raised Face Of SO Flanges | Hight (H) | Wall Thickness Of (Raised Face) |

(T1) | Flat Face (FF) (T2) |

SORF Bolts Holes | SO Flange Bolt Hole Number |

| 3 | 3.57 | 9.50 | 7.50 | 5.00 | .250 | 5.00 | 2.38 | 1.50 | 2.13 | 1.00 | 8 |

| 4 | 4.57 | 11.50 | 9.25 | 6.19 | .250 | 6.25 | 3.00 | 1.75 | 2.75 | 1.25 | 8 |

| 5 | 5.66 | 13.75 | 11.00 | 7.31 | .250 | 7.50 | 3.38 | 3.00 | 3.13 | 1.38 | 8 |

| 6 | 6.72 | 15.00 | 12.50 | 8.50 | .250 | 9.25 | 3.63 | 2.19 | 3.38 | 1.25 | 12 |

| 8 | 8.72 | 18.50 | 15.50 | 10.63 | .250 | 11.75 | 4.25 | 2.50 | 4.00 | 1.50 | 12 |

| 10 | 10.88 | 21.50 | 18.50 | 12.75 | .250 | 14.50 | 4.50 | 2.75 | 4.25 | 1.50 | 16 |

| 12 | 12.88 | 24.00 | 21.00 | 15.00 | .250 | 16.50 | 4.88 | 3.13 | 4.63 | 1.50 | 20 |

| 14 | 14.14 | 25.25 | 22.00 | 16.25 | .250 | 17.75 | 5.38 | 3.38 | 5.13 | 1.63 | 20 |

| 16 | 16.16 | 27.75 | 24.25 | 18.50 | .250 | 20.00 | 5.50 | 3.50 | 5.25 | 1.75 | 20 |

| 18 | 18.18 | 31.00 | 27.00 | 21.00 | .250 | 22.25 | 6.25 | 4.00 | 6.00 | 2.00 | 20 |

| 20 | 20.20 | 33.75 | 29.50 | 23.00 | .250 | 24.50 | 6.50 | 4.25 | 6.25 | 2.13 | 20 |

| 24 | 24.25 | 41.00 | 35.50 | 27.25 | .250 | 29.50 | 8.25 | 5.50 | 8.00 | 2.63 | 20 |

| Normal Size Of Steel Pipe | Inner Daimeter | (Outside Daimeter) For O.D. | Bolt Circle For (BC) | R For (Raised) | Raised Face (RF) | SORF Hight (H) | (RF) Wall Thickness | (T1) | Flat Face (T2) | SORF Flanges Bolt Hole | SORF Bolts Holes Number |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 4.75 | 3.25 | 1.38 | .250 | 1.50 | 1.50 | 0.88 | 1.25 | 0.88 | 4 |

| 3/4 | 1.09 | 5.13 | 3.50 | 1.69 | .250 | 1.75 | 1.63 | 1.00 | 1.38 | 0.88 | 4 |

| 1 | 1.36 | 5.88 | 4.00 | 2.00 | .250 | 2.06 | 1.88 | 1.13 | 1.63 | 1.00 | 4 |

| 1-1/4 | 1.70 | 6.25 | 4.38 | 2.50 | .250 | 2.50 | 1.88 | 1.13 | 1.63 | 1.00 | 4 |

| 1-1/2 | 1.95 | 7.00 | 4.88 | 2.88 | .250 | 2.75 | 2.00 | 1.25 | 1.75 | 1.13 | 4 |

| 2 | 2.44 | 8.50 | 6.50 | 3.63 | .250 | 4.13 | 2.50 | 1.50 | 2.25 | 1.00 | 8 |

| 2-1/2 | 2.94 | 9.63 | 7.50 | 4.13 | .250 | 4.88 | 2.75 | 1.63 | 2.50 | 1.13 | 8 |

| 3 ** | 3.57 | 10.50 | 8.00 | 5.00 | .250 | 5.25 | 3.13 | 1.88 | 2.88 | 1.25 | 8 |

| 4 ** | 4.57 | 12.25 | 9.50 | 6.19 | .250 | 6.38 | 3.81 | 2.13 | 3.56 | 1.38 | 8 |

| 5 ** | 5.66 | 14.75 | 11.50 | 7.31 | .250 | 7.75 | 4.38 | 2.88 | 4.13 | 1.63 | 8 |

| 6 ** | 6.72 | 15.50 | 12.50 | 8.50 | .250 | 9.00 | 4.94 | 3.25 | 4.69 | 1.50 | 12 |

| 8 ** | 8.72 | 19.00 | 15.50 | 10.63 | .250 | 11.50 | 5.88 | 3.63 | 5.63 | 1.75 | 12 |

| 10 ** | 10.88 | 23.00 | 19.00 | 12.75 | .250 | 14.50 | 6.50 | 4.25 | 6.25 | 2.00 | 12 |

| 12 ** | 12.88 | 26.50 | 22.50 | 15.00 | .250 | 17.75 | 7.38 | 4.88 | 7.13 | 2.13 | 16 |

| Normal Size Of Steel Pipe | Inner Daimeter | Outer Diameter | SORF Circle Bolt (B.C.) | R For (Raised) | Raised Face For (RF) | SORF Hight (H) | Thickness Of Raised Face (T) | (T1) | Thickness Of Flat Face (T2) | Bolt Hole (B) | Numbers of Bolts Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 5.25 | 3.50 | 1.38 | .250 | 1.69 | 1.81 | 1.19 | 1.56 | 0.88 | 4 |

| 3/4 | 1.09 | 5.50 | 3.75 | 1.69 | .250 | 2.00 | 1.94 | 1.25 | 1.69 | 0.88 | 4 |

| 1 | 1.36 | 6.25 | 4.25 | 2.00 | .250 | 2.25 | 2.13 | 1.38 | 1.88 | 1.00 | 4 |

| 1-1/4 | 1.70 | 7.25 | 5.13 | 2.50 | .250 | 2.88 | 2.31 | 1.50 | 2.06 | 1.13 | 4 |

| 1-1/2 | 1.95 | 8.00 | 5.75 | 2.88 | .250 | 3.13 | 2.63 | 1.75 | 2.38 | 1.25 | 4 |

| 2 | 2.44 | 9.25 | 6.75 | 3.63 | .250 | 3.75 | 3.00 | 2.00 | 2.75 | 1.13 | 8 |

| 2-1/2 | 2.94 | 10.50 | 7.75 | 4.13 | .250 | 4.50 | 3.38 | 2.25 | 3.13 | 1.25 | 8 |

| 3 | 3.57 | 12.00 | 9.00 | 5.00 | .250 | 5.25 | 3.88 | 2.63 | 3.63 | 1.38 | 8 |

| 4 | 4.57 | 14.00 | 10.75 | 6.19 | .250 | 6.50 | 4.50 | 3.00 | 4.25 | 1.63 | 8 |

| 5 | 5.66 | 16.50 | 12.75 | 7.31 | .250 | 8.00 | 5.38 | 3.63 | 5.13 | 1.88 | 8 |

| 6 | 6.72 | 19.00 | 14.50 | 8.50 | .250 | 9.25 | 6.25 | 4.25 | 6.00 | 2.13 | 8 |

| 8 | 8.72 | 21.75 | 17.25 | 10.63 | .250 | 12.00 | 7.25 | 5.00 | 7.00 | 2.13 | 12 |

| 10 | 10.88 | 26.50 | 21.25 | 12.75 | .250 | 14.75 | 9.25 | 6.50 | 9.00 | 2.63 | 12 |

| 12 | 12.88 | 30.00 | 24.38 | 15.00 | .250 | 17.38 | 10.25 | 7.25 | 10.00 | 2.88 | 12 |

|

NPS

|

Weight In Kilogram

|

|

DN

|

KG

|

| 10 | 0.60 |

| 15 | 0.67 |

| 20 | 0.94 |

| 25 | 1.11 |

| 32 | 1.62 |

| 40 | 1.85 |

| 50 | 2.46 |

| 65 | 2.99 |

| 80 | 3.61 |

| 100 | 3.99 |

| 125 | 5.41 |

| 150 | 6.55 |

| 175 | 8.42 |

| 200 | 8.97 |

| 250 | 12.76 |

| 300 | 16.60 |

| 350 | 24.08 |

| 400 | 30.20 |

| 450 | 41.67 |

| 500 | 52.87 |

| 600 | 77.58 |

| 700 | 77.13 |

| 800 | 106.35 |

| 900 | 125.39 |

| 1000 | 177.99 |

|

NPS

|

Weight In KG

|

|

DN

|

KG |

| 15 | 0.71 |

| 20 | 1.01 |

| 25 | 1.23 |

| 32 | 1.81 |

| 40 | 2.09 |

| 50 | 2.88 |

| 65 | 3.65 |

| 80 | 4.61 |

| 100 | 5.65 |

| 125 | 8.13 |

| 150 | 10.44 |

| 175 | 8.42 |

| 200 | 16.48 |

| 250 | 23.99 |

| 300 | 30.73 |

| 350 | 42.56 |

| 400 | 60.68 |

| 450 | 71.74 |

| 500 | 96.4 |

| 600 | 145.6 |

| 700 | 77.13 |

| 800 | 106.35 |

| Normal Pipe Size

In (Inches) |

DN (Millimeter) |

ASME B16.5 Slip On Flange Weight In (KGS) |

| 1/ 2 | 15 | 0.4 |

| 3/ 4 | 20 | 0.6 |

| 1 | 25 | 0.8 |

| 1 1/ 4 | 32 | 1 |

| 1 1/ 2 | 40 | 1.3 |

| 2 | 50 | 2.1 |

| 2 1/ 2 | 65 | 3.3 |

| 3 | 80 | 3.9 |

| 3 1/ 2 | 90 | 4.8 |

| 4 | 100 | 5.3 |

| 5 | 125 | 6.1 |

| 6 | 150 | 7.5 |

| 8 | 200 | 12.1 |

| 10 | 250 | 16.5 |

| 12 | 300 | 26.2 |

| 14 | 350 | 34.6 |

| 16 | 400 | 44.8 |

| 18 | 450 | 48.9 |

| 20 | 500 | 61.9 |

| 24 | 600 | 86.9 |

| (Normal Size Of Steel Pipes) In Inch | (I.D.) Inner Daimeter Gasket |

(O.D.) Outer Daimeter Gasket | ||||

|---|---|---|---|---|---|---|

| Class 150#/ LB | Class 300#/ LB | Class 400#/ LB | Class 600#/ LB | Class 900#/ LB | ||

| 1/2 | 0.84 | 1.875 | 2.125 | 2.125 | 2.125 | 2.50 |

| 3/4 | 1.06 | 2.25 | 2.625 | 2.625 | 2.625 | 2.75 |

| 1 | 1.31 | 2.625 | 2.875 | 2.875 | 2.875 | 3.125 |

| 1 1/4 | 1.66 | 3 | 3.25 | 3.25 | 3.25 | 3.50 |

| 1 1/2 | 1.91 | 3.375 | 3.75 | 3.75 | 3.75 | 3.875 |

| 2 | 2.38 | 4.125 | 4.375 | 4.375 | 4.375 | 5.625 |

| 2 1/2 | 2.88 | 4.875 | 5.125 | 5.125 | 5.125 | 6.50 |

| 3 | 3.50 | 5.375 | 5.875 | 5.875 | 5.875 | 6.625 |

| 4 | 4.50 | 6.875 | 7.125 | 7.00 | 7.625 | 8.125 |

| 5 | 5.56 | 7.75 | 8.50 | 8.375 | 9.50 | 9.75 |

| 6 | 6.62 | 8.75 | 9.875 | 9.75 | 10.50 | 11.375 |

| 8 | 8.62 | 11 | 12.125 | 12.00 | 12.625 | 14.125 |

| 10 | 10.75 | 13.375 | 14.25 | 14.125 | 15.75 | 17.125 |

| 12 | 12.75 | 16.125 | 16.625 | 16.50 | 18.00 | 19.625 |

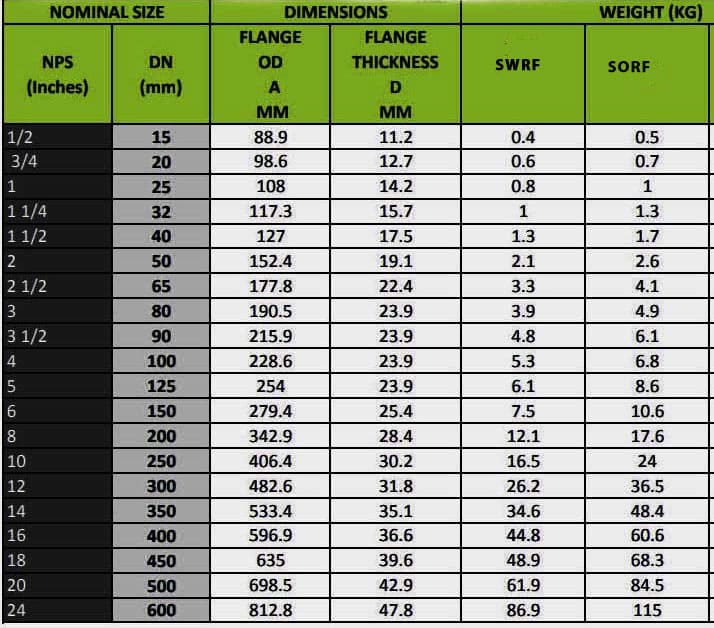

| Normal Size Of Steel Pipe In Inches | Size In Millimeter | SORF Flanges Outer Daimeter (O.D.) In (MM) |

SORF Flanges Wall Thickness Of (D) (In M) |

ASME B16.5 Slip On Flange |

|---|---|---|---|---|

| 1/2 | 15 | 88.9 | 11.2 | 0.4 |

| 3/4 | 20 | 98.6 | 12.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 |

| 1 1/4 | 32 | 117.3 | 15.7 | 1 |

| 1 1/2 | 40 | 127 | 17.5 | 1.3 |

| 2 | 50 | 152.4 | 19.1 | 2.1 |

| 2 1/2 | 65 | 177.8 | 22.4 | 3.3 |

| 3 | 80 | 190.5 | 23.9 | 3.9 |

| 3 1/2 | 90 | 215.9 | 23.9 | 4.8 |

| 4 | 100 | 228.6 | 23.9 | 5.3 |

| 5 | 125 | 254 | 23.9 | 6.1 |

| 6 | 150 | 279.4 | 25.4 | 7.5 |

| 8 | 200 | 342.9 | 28.4 | 12.1 |

| 10 | 250 | 406.4 | 30.2 | 16.5 |

| 12 | 300 | 482.6 | 31.8 | 26.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 |

| 16 | 400 | 596.9 | 36.6 | 44.8 |

| 18 | 450 | 635 | 39.6 | 48.9 |

| 20 | 500 | 698.5 | 42.9 | 61.9 |

|

Normal Pipe Size |

DN |

|---|---|

|

1/2 |

15 |

|

3/4 |

20 |

|

1 |

25 |

|

1 1/4 |

32 |

|

1 1/2 |

40 |

|

2 |

50 |

|

2 1/2 |

65 |

|

3 |

80 |

|

4 |

100 |

| Outer Diameter * | |

|---|---|

| ≤ 24 = 1.6 (mm) | > 24 = ± 3.2 (mm) |

| Inner Diameter | |

|---|---|

| ≤ 10 = ± 0.8 (mm) | ≥ 12 = + 1.6 (mm) / - 0 (mm) |

| O.D. of Hub | |

|---|---|

| ≤ 12 = + 2.4 (mm) / - 1.6 (mm) | ≥ 14 = ± 3.2 (mm) |

| Counterbore Diameter |

|---|

| Same as for I.D. |

| Drilling | |

|---|---|

| Bolt Circle (B.C.)= 1.6 (mm) | Bolt Hole Spacing = ± 0.8 (mm) |

| Bolt Circle Eccentricity | |

|---|---|

| ≤ 2.1/2 = 0.8 (mm) maximum | ≥ 3 = 1.6 (mm) maximum |

| Thickness | |

|---|---|

| ≤ 18 = + 3.2 (mm) / - 0 | ≥ 20 = + 4.8 (mm) / - 0 |

| Length Of thru Hub | |

|---|---|

| ≤ 18 = + 3.2 millimeter / - 0.8 millimeter | ≥ 20 = + 4.8 millimeter / - 1.6 millimeter |

| Contact Face Diameter | ||

|---|---|---|

| 1.6 millimeter Raised Face = ± 0.8 millimeter | 6.35 millimeter Raised Face, Tongue and Groove | Male And Female = ± 0.4 millimeter |