MSS-SP-43 Fittings The MSS-SP-43 standard provides guidelines for the dimensions, tolerances, materials, and markings of stainless steel butt-welding fittings. These fittings are commonly used in piping systems where the joining of stainless steel pipes is required. It's important to note that standards and specifications may be updated or revised over time, so it's advisable to check the latest edition of the MSS-SP-43 standard or any relevant updates from the Manufacturers Standardization Society for the most current information.

| Specifications | MSS-SP-43 Fittings |

|---|---|

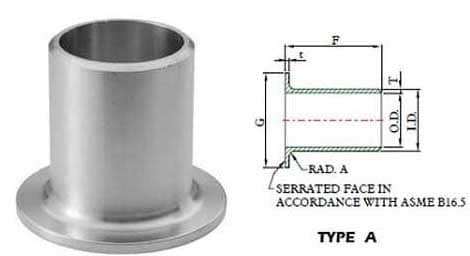

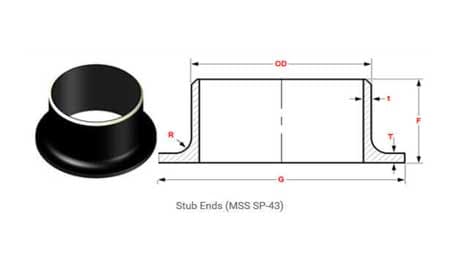

| Mss Sp-43 Stub End | Mss Sp-43 Type A Stub End Mss Sp-43 Type B Stub End |

| Schedule | SCH 10 To SCH 180. |

| Manufacturer Size | NPS 1⁄₂"/ 2"/ 4"/ 6"/ 8" |

| Method | Seamless Welded Butt-Weld Fabricated |

| Different Ends Finishing: | Beveled Ends Flanged Ends Squared Ends |

| Mss-sp-43 Stub End Use | Stub End Fittings can be described as mechanical joints. |

| Manufacturer Type A Stub End | Mss-sp-43 Short Stub End Mss-sp-43 Long Stub End |

| material | Incoloy, Alloy 20, Duplex Steel, Tantalum, Carbon Steel, Super Duplex, Hastalloy, Alloy Steel, Brass, Cupro-Nickel Inconel, Monel, Bronze, Stainless Steel, Nickel Alloys. |

| Normal Pipe Size | Outer Diameter | (T) | (G) | (F) | (R) Type A |

R Type B |

| 1/2 | 21.3 | 2.11 | 34.9 | 50.8 | 3.05 | 0.76 |

| 3/4 | 26.7 | 2.11 | 42.9 | 50.8 | 3.05 | 0.76 |

| 1 | 33.4 | 2.77 | 50.8 | 50.8 | 3.05 | 0.76 |

| 1.1/4 | 42.2 | 2.77 | 63.5 | 50.8 | 4.83 | 0.76 |

| 1.1/2 | 48.3 | 2.77 | 73 | 50.8 | 6.35 | 0.76 |

| 2 | 60.3 | 2.77 | 92.1 | 63.5 | 7.87 | 0.76 |

| 2.1/2 | 73 | 3.05 | 104.8 | 63.5 | 7.87 | 0.76 |

| 3 | 88.9 | 3.05 | 127 | 63.5 | 9.65 | 0.76 |

| 3.1/2 | 101.6 | 3.05 | 139.7 | 76.2 | 9.65 | 0.76 |

| 4 | 114.3 | 3.05 | 157.2 | 76.2 | 11.18 | 0.76 |

| 5 | 141.3 | 3.40 | 185.7 | 76.2 | 11.18 | 1.52 |

| 6 | 168.3 | 3.40 | 215.9 | 88.9 | 12.7 | 1.52 |

| 8 | 219.1 | 3.76 | 269.9 | 101.6 | 12.7 | 1.52 |

| 10 | 273.1 | 4.19 | 323.9 | 127 | 12.7 | 1.52 |

| 12 | 323.9 | 4.57 | 381 | 152.4 | 12.7 | 1.52 |

| 14 | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 1.52 |

| 16 | 406.4 | 4.78 | 469.9 | 152.4 | 12.7 | 1.52 |

| 18 | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 1.52 |

| 20 | 508 | 5.54 | 584.2 | 152.4 | 12.70 | 1.52 |

| 24 | 609.6 | 6.35 | 692.2 | 152.4 | 12.7 | 1.52 |

| Normal Pipe Size | Outside Diameter | (T) | (G) | (F) | (R) | Kilogram |

|---|---|---|---|---|---|---|

| 1/2 | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 |

| 3/4 | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 |

| 1 | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 |

| 1¼ | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 |

| 1½ | 48.3 | 2.77 | 73 | 50.8 | 6.35 | 0.25 |

| 2 | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 |

| 2½ | 73 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 |

| 3 | 88.9 | 3.05 | 127 | 63.5 | 9.53 | 0.73 |

| 4 | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 |

| 5 | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 |

| 6 | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 |

| 8 | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 |

| 10 | 273.1 | 4.19 | 323.9 | 127 | 12.70 | 5.13 |

| 12 | 323.9 | 4.57 | 381 | 152.4 | 12.70 | 8.16 |

| 14 | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 |

| 16 | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 |

| 18 | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 |

| 20 | 508 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 |

| 24 | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 |

| Normal Pipe Size In inch |

MSS Sp 43 STUB ENDS | |||

| Schedule 5S |

Schedule 10S |

Schedule 40S |

Schedule 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| NPS | 1/2 up to 2.1/2 | 3 to 3.1/2 | 4 | 5 to 8 | 10 to 18 | 20 to 24 |

| O.D. at Welding End (Outside Diameter) | + 1.6 - 0.8 |

1.6 | 1.6 | + 2.29 - 1.6 |

+ 4.06 - 3.05 |

+ 6.35 - 4.83 |

| Overall Length Of ((F)) | 1.6 | 1.6 | 1.6 | 1.6 | 2 | 2 |

| O.D. of Lap ((G)) | + 0 - 0.76 |

+ 0 - 0.76 |

+ 0 - 0.76 |

+ 0 - 0.76 |

+ 0 - 1.6 |

+ 0 - 1.6 |

| Wall Thickness of Lap ((T)) | + 1.52 - 0 |

+ 1.52 - 0 |

+ 1.52 - 0 |

+ 1.52 - 0 |

+ 1.52 - 0 |

+ 1.52 - 0 |

| Lap Fillet Radius of ((R)) | + 0 - 0.76 |

+ 0 - 0.76 |

+ 0 - 1.6 |

+ 0 - 1.6 |

+ 0 - 1.6 |

+ 0 - 1.6 |

| Outside Daimeter (O.D.) & Inside Daimeter (I.D.) | List Of Equivalent | (NPS) | Size Of Threads In Inch |

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 | 0.540 | 1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

| 1-21/32 | 1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

| MSS SP-43 Stub Ends Pressure Ratings | |||||

|---|---|---|---|---|---|

| MSS SP-43 Type A Stub End Temperature Ratings | Types Of Pressure Ratings Class | ||||

| Class 150# | Class 300# | ||||

| 1/4 - 1 (Inch) | 1 1/4 - 2 (Inch) | 2 1/2 - 3 (Inch) | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

| Normal Size Of Pipe (DN) |

Schedule Number |

Outer Daimeter In inch millmeter |

Wall Thickness inch millmeter |

Mass lb/ft kg/m |

|---|---|---|---|---|

| 1/8 6 |

5S | 0.405 10.3 |

... | ... |

| 1/8 6 |

10S | 0.405 10.3 |

0.049 1.24 |

0.19 0.28 |

| 1/8 6 |

40S | 0.405 10.3 |

0.068 1.73 |

0.24 0.37 |

| 1/8 6 |

80S | 0.405 10.3 |

0.095 2.41 |

0.31 0.47 |

| 1/4 8 |

5S | 0.540 13.7 |

... | ... |

| 1/4 8 |

10S | 0.540 13.7 |

0.065 1.65 |

0.33 0.49 |

| 1/4 8 |

40S | 0.540 13.7 |

0.088 2.24 |

0.43 0.63 |

| 1/4 8 |

80S | 0.540 13.7 |

0.119 3.02 |

0.54 0.80 |

| 3/8 10 |

5S | 0.675 17.1 |

... | ... |

| 3/8 10 |

10S | 0.675 17.1 |

0.065 1.65 |

0.42 0.63 |

| 3/8 10 |

40S | 0.675 17.1 |

0.091 2.31 |

0.57 0.84 |

| 3/8 10 |

80S | 0.675 17.1 |

0.126 3.20 |

0.74 1.10 |

| 1/2 15 |

5S | 0.840 21.3 |

0.065 1.65 |

0.54 0.80 |

| 1/2 15 |

10S | 0.840 21.3 |

0.083 2.11 |

0.67 1.00 |

| 1/2 15 |

40S | 0.840 21.3 |

0.109 2.77 |

0.85 1.27 |

| 1/2 15 |

80S | 0.840 21.3 |

0.147 3.73 |

1.09 1.62 |

| 3/4 20 |

5S | 1.050 26.7 |

0.065 1.65 |

0.68 1.02 |

| 3/4 20 |

10S | 1.050 26.7 |

0.083 2.11 |

0.86 1.28 |

| 3/4 20 |

40S | 1.050 26.7 |

0.113 2.87 |

1.13 1.69 |

| 3/4 20 |

80S | 1.050 26.7 |

0.154 3.91 |

1.48 2.20 |

| 1 25 |

5S | 1.315 33.4 |

0.065 1.65 |

0.68 1.02 |

| 1 25 |

10S | 1.315 33.4 |

0.083 2.11 |

0.86 1.28 |

| 1 25 |

40S | 1.315 33.4 |

0.133 3.38 |

1.68 2.50 |

| 1 25 |

80S | 1.315 33.4 |

0.179 4.55 |

2.17 3.24 |

| 1-1/4 32 |

5S | 1.660 42.2 |

0.065 1.65 |

1.11 1.65 |

| 1-1/4 32 |

10S | 1.660 42.2 |

0.109 2.77 |

1.81 2.69 |

| 1-1/4 32 |

40S | 1.660 42.2 |

0.140 3.56 |

2.27 3.39 |

| 1-1/4 32 |

80S | 1.660 42.2 |

0.191 4.85 |

3.00 4.47 |

| 1-1/2 40 |

5S | 1.900 48.3 |

0.065 1.65 |

1.28 1.90 |

| 1-1/2 40 |

10S | 1.900 48.3 |

0.109 2.77 |

2.09 3.11 |

| 1-1/2 40 |

40S | 1.900 48.3 |

0.145 3.68 |

2.72 4.05 |

| 1-1/2 40 |

80S | 1.900 48.3 |

0.200 5.08 |

3.63 5.41 |

| 2 50 |

5S | 2.375 60.3 |

0.065 1.65 |

1.61 2.39 |

| 2 50 |

10S | 2.375 60.3 |

0.109 2.77 |

2.64 3.93 |

| 2 50 |

40S | 2.375 60.3 |

0.154 3.91 |

3.66 5.44 |

| 2 50 |

80S | 2.375 60.3 |

0.218 5.54 |

5.03 7.48 |

| 2-1/2 65 |

5S | 2.875 73 |

0.083 2.11 |

2.48 3.69 |

| 2-1/2 65 |

10S | 2.875 73 |

0.120 3.05 |

3.53 5.26 |

| 2-1/2 65 |

40S | 2.875 73 |

0.203 5.16 |

5.80 8.63 |

| 2-1/2 65 |

80S | 2.875 73 |

0.276 7.01 |

7.67 11.41 |

| 3 80 |

5S | 3.500 88.9 |

0.083 2.11 |

3.03 4.52 |

| 3 80 |

10S | 3.500 88.9 |

0.120 3.05 |

4.34 6.46 |

| 3 80 |

40S | 3.500 88.9 |

0.216 5.49 |

7.58 11.29 |

| 3 80 |

80S | 3.500 88.9 |

0.300 7.62 |

10.26 15.27 |

| 3-1/2 90 |

5S | 4.000 101.6 |

0.083 2.11 |

3.48 5.18 |

| 3-1/2 90 |

10S | 4.000 101.6 |

0.120 3.05 |

4.98 7.41 |

| 3-1/2 90 |

40S | 4.000 101.6 |

0.226 5.74 |

9.12 13.57 |

| 3-1/2 90 |

80S | 4.000 101.6 |

0.318 8.08 |

12.52 18.64 |

| 4 100 |

5S | 4.500 114.3 |

0.083 2.11 |

3.92 5.84 |

| 4 100 |

10S | 4.500 114.3 |

0.120 3.05 |

5.62 8.37 |

| 4 100 |

40S | 4.500 114.3 |

0.237 6.02 |

10.80 16.08 |

| 4 100 |

80S | 4.500 114.3 |

0.337 8.56 |

15.00 22.32 |

| 5 125 |

5S | 5.563 141.3 |

0.109 2.77 |

6.36 9.46 |

| 5 125 |

10S | 5.563 141.3 |

0.134 3.40 |

7.78 11.56 |

| 5 125 |

40S | 5.563 141.3 |

0.258 6.55 |

14.63 21.77 |

| 5 125 |

80S | 5.563 141.3 |

0.375 9.53 |

20.80 30.97 |

| 6 150 |

5S | 6.625 168.3 |

0.109 2.77 |

7.59 11.31 |

| 6 150 |

10S | 6.625 168.3 |

0.134 3.40 |

9.30 13.83 |

| 6 150 |

40S | 6.625 168.3 |

0.280 7.11 |

18.99 28.26 |

| 6 150 |

80S | 6.625 168.3 |

0.432 10.97 |

28.60 42.56 |

| Normal Size Of Pipe In Inches | NB | Outside Daimeter | Wall Thickness | schedule 10 | schedule 20 | schedule 30 | schedule 40 | schedule 80 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 NB | 21.30 | 1.65 | 2.11 | __ | 2.41 | 2.77 | 3.73 |

| 3/4 | 20 NB | 26.70 | 1.65 | 2.11 | __ | 2.41 | 2.87 | 3.91 |

| 1 | 25 NB | 33.40 | 1.65 | 2.77 | __ | 2.90 | 3.38 | 4.55 |

| 1 1/4 | 32 NB | 42.20 | 1.65 | 2.77 | __ | 2.97 | 3.56 | 4.85 |

| 1 1/2 | 40 NB | 48.30 | 1.65 | 2.77 | __ | 3.18 | 3.68 | 5.08 |

| 2 | 50 NB | 60.30 | 1.65 | 2.77 | __ | 3.18 | 3.91 | 5.54 |

| 2 1/2 | 65 NB | 73.00 | 2.11 | 3.05 | __ | 4.78 | 5.16 | 7.01 |

| 3 | 80 NB | 88.90 | 2.11 | 3.05 | __ | 4.78 | 5.49 | 7.62 |

| 3 1/2 | 90 NB | 101.60 | 2.11 | 3.05 | __ | 4.78 | 5.74 | 8.08 |

| 4 | 100 NB | 114.30 | 2.11 | 3.05 | __ | 4.78 | 6.02 | 8.56 |

| 5 | 125 NB | 141.30 | 2.77 | 3.40 | __ | __ | 6.55 | 9.53 |

| 6 | 150 NB | 168.30 | 2.77 | 3.40 | __ | __ | 7.11 | 10.97 |

| 8 | 200 NB | 219.10 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 12.70 |

| 10 | 250 NB | 273.00 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 15.09 |

| 12 | 300 NB | 323.80 | 3.96 | 4.57 | 6.35 | 8.38 | 10.31 | 17.48 |

| 14 | 350 NB | 355.60 | 3.96 | 6.35 | 7.92 | 9.53 | 11.13 | 19.05 |

| 16 | 400 NB | 406.40 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 | 21.44 |

| 18 | 450 NB | 457.00 | 4.19 | 6.35 | 7.92 | 11.13 | 14.27 | 23.83 |

| 20 | 500 NB | 508.00 | 4.78 | 6.35 | 9.53 | 12.70 | 15.09 | 26.19 |

| 22 | 550 NB | 559.00 | 4.78 | 6.35 | 9.53 | 12.70 | __ | 28.58 |

| 24 | 600 NB | 610.00 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 30.96 |

MSS SP-43 provides requirements for fabricated and wrought butt-welding fittings intended for low pressure, corrosion resistant applications. Requirements covered include size, marking, metal thickness, dimensions, pressure ratings, materials, testing, and tolerances

| (Normal Size Of Pipe) | Type Of Schedule | (D) | (T) | (G) | (F) | R. Maximum | Kilogram And St. | |

|---|---|---|---|---|---|---|---|---|

| 1/2 “ | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 “ | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 “ | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 “ | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 “ | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 “ | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 “ | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 “ | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 “ | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 “ | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 “ | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 “ | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 “ | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 “ | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |