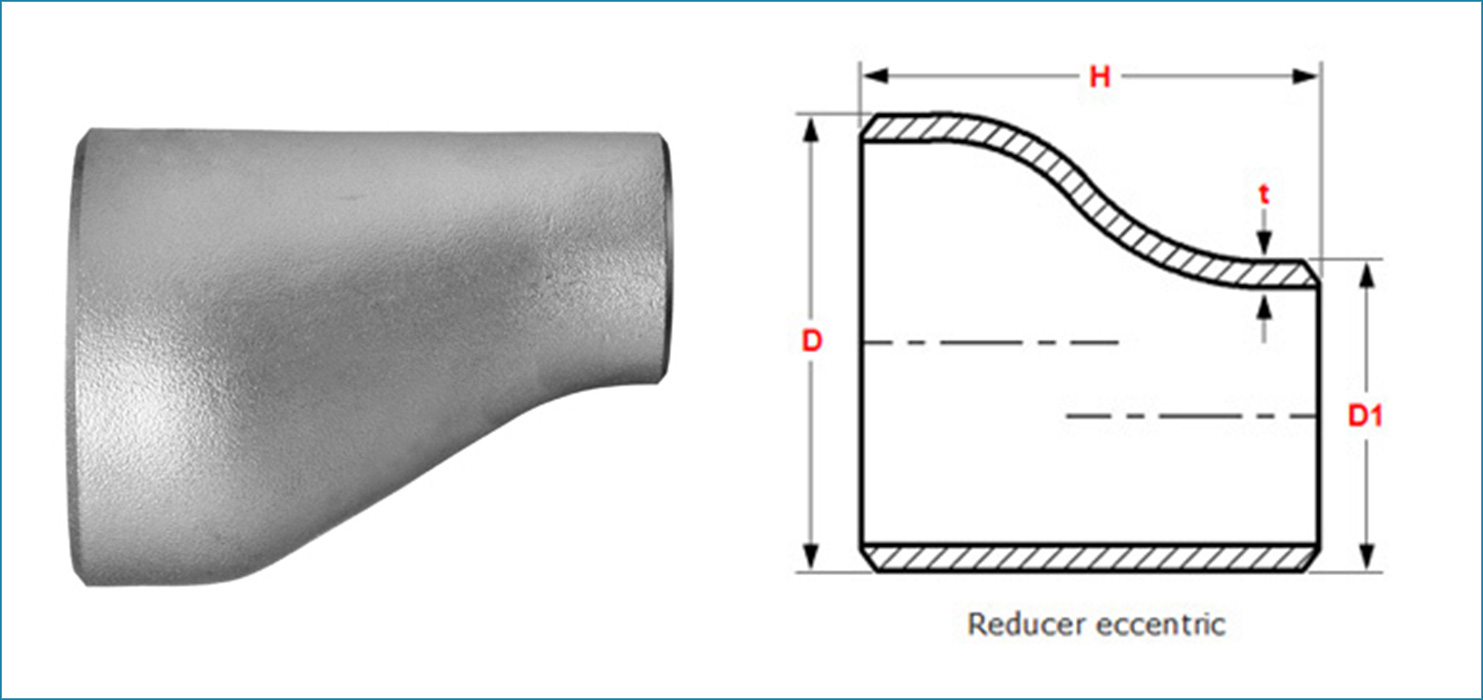

Pipe Fitings Chromoly Alloy Eccentric Reducer The ASME B16.9 Eccentric Reducer is a variation of pipe reducers. These reducers are used in pipe fittings as a connector, to connect two pipes of varying or different diameters . A pipe reducer that is constructed of steel can have a flat bottom face, while maintaining one side of fitting. This kind of fitting is referred to as a Butt Weld Eccentric Reducer Schedule 40. Generally, Asme B16 9 Eccentric Reducer Dimensions are utilized in a Horizontal piping system. At ___, we manufacture forged fittings from various alloys such as SS Eccentric Reducer in accordance to international standards like the ANSI / ASME B16.9. The list of materials used by us to manufacture the Grooved Eccentric Reducer are - Stainless steel, Carbon steel, Alloy steel, High performance Nickel Alloys & Duplex steel.

ASME B16.9 Eccentric Reducer constructed from duplex grade stainless steel or nickel based alloys such as Monel, Inconel etc are known to have excellent resistance to chloride-ion stress related corrosion cracking. Besides this property, Carbon Steel Eccentric Reducer Material shows appropriate resistance to a number of oxidizing environments as well. The ASME B16.9 Eccentric Reducer produced from Incoloy tend to be very resistant to oxidation as well as chemical corrosion. Further, most reducers in our stock list has a low creep rate under high stresses at elevated temperatures. Besides these two properties, Eccentric Reducer Schedule 40 has some high stress-rupture effectiveness after the Carbon Steel Eccentric Reducer Material has been processed with a suitable heat treatment as well.

The regular production at our factory, including stock items include reducers made from different alloy grades like stainless steel reducers, carbon steel reducers, alloy steel reducers and duplex steel reducers. The CS Eccentric Reducer are primarily used to adapt pipes of different sizes in a pipeline system. ANSI B16.9 Pipe reducers could largely be classified in two types – a concentric reducer and Stainless Steel Eccentric Reducer B16.9.

| Specifications | ASME B16.9 Eccentric Reducer |

|---|---|

| Eccentric Reducer Schedule 80 Pipe Fittings size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| Eccentric Buttweld Reducer Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Eccentric Reducer b16.9 Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Eccentric Pipe Reducer Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Eccentric Reducer Schedule 40 Type | DN15-DN1200 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Stainless Steel Eccentric Reducer B16.9 Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Eccentric Buttweld Reducer Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D,

6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process for CS Eccentric Reducer | Push, Press, Forge, Cast, etc. |

| Eccentric Pipe Reducer Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills For Carbon Steel Eccentric Reducer Material | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for SS Eccentric Reducer |

|

| Eccentric Reducer Schedule 40 Application |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| Code RCD REISO | Ø BIG | Ø SMALL | HEIGHT H mm | THEORETICAL WEIGHT KG | ||||

|---|---|---|---|---|---|---|---|---|

| DN | D mm | Thickness S mm | DN | d mm | Thickness s mm | |||

| 27 21 | 3/4 | 26.9 | 2.3 | 1/2 | 21.3 | 2.0 | 38 | 0.08 |

| 33 21 | 1 | 33.7 | 2.6 | 1/2 | 21.3 | 2.0 | 50 | 0.09 |

| 33 27 | 3/4 | 26.9 | 2.3 | 0.09 | ||||

| 42 21 | 1″1/4 | 42.4 | 2.6 | 1/2 | 21.3 | 2.0 | 50 | 0.12 |

| 42 27 | 3/4 | 26.9 | 2.3 | 0.13 | ||||

| 42 33 | 1 | 33.7 | 2.6 | 0.14 | ||||

| *48 21 | 1″1/2 | 48.3 | 2.6 | 1/2 | 21.3 | 2.0 | 64 | 0.18 |

| 48 27 | 3/4 | 26.9 | 2.3 | 0.19 | ||||

| 48 33 | 1 | 33.7 | 2.6 | 0.20 | ||||

| 48 42 | 1″1/4 | 42.4 | 2.6 | 0.20 | ||||

| 60 27 | 2 | 60.3 | 2.9 | 3/4 | 26.9 | 2.3 | 76 | 0.30 |

| 60 33 | 1 | 33.7 | 2.6 | 0.31 | ||||

| 60 42 | 1″1/4 | 42.4 | 2.6 | 0.32 | ||||

| 60 48 | 1″1/2 | 48.3 | 2.6 | 0.33 | ||||

| 76 33 | 2″1/2 | 76.1 | 2.9 | 1 | 33.7 | 2.6 | 90 | 0.40 |

| 76 42 | 1″1/4 | 42.4 | 2.6 | 0.47 | ||||

| 76 48 | 1″1/2 | 48.3 | 2.6 | 0.48 | ||||

| 76 60 | 2 | 60.3 | 2.6 | 0.49 | ||||

| 89 42 | 3 | 88.9 | 3.2 | 1″1/4 | 42.4 | 2.6 | 90 | 0.55 |

| 89 48 | 1″1/2 | 48.3 | 2.6 | 0.61 | ||||

| 89 60 | 2 | 60.3 | 2.9 | 0.62 | ||||

| 89 76 | 2″1/2 | 76.1 | 2.9 | 0.63 | ||||

| 114 48 | 4 | 114.3 | 3.6 | 1″1/2 | 48.3 | 2.6 | 100 | 0.85 |

| 114 60 | 2 | 60.3 | 2.9 | 0.98 | ||||

| 114 76 | 2″1/2 | 76.1 | 2.9 | 1.00 | ||||

| 114 89 | 3 | 88.9 | 3.2 | 1.02 | ||||

| 139 60 | 5 | 139.7 | 4.0 | 2 | 60.3 | 2.9 | 127 | 1.60 |

| 139 76 | 2″1/2 | 76.1 | 2.9 | 1.70 | ||||

| 139 89 | 3 | 88.9 | 3.2 | 1.74 | ||||

| 139 114 | 4 | 114.3 | 3.6 | 1.76 | ||||

| *168 76 | 6 | 168.3 | 4.5 | 2″1/2 | 76.1 | 2.9 | 140 | 2.60 |

| 168 89 | 3 | 88.9 | 3.2 | 2.70 | ||||

| 168 114 | 4 | 114.3 | 3.6 | 2.82 | ||||

| 168 139 | 5 | 139.7 | 4.0 | 2.94 | ||||

| 219 114 | 8 | 219.1 | 6.3 | 4 | 114.3 | 3.6 | 152 | 5.03 |

| 219 139 | 5 | 139.7 | 4.0 | 5.12 | ||||

| 219 168 | 6 | 168.3 | 4.5 | 5.18 | ||||

| *273 114 | 10 | 273.0 | 6.3 | 4 | 114.3 | 3.6 | 178 | 7.00 |

| *273 139 | 5 | 139.7 | 4.0 | 7.20 | ||||

| 273 168 | 6 | 168.3 | 4.5 | 7.40 | ||||

| 273 219 | 8 | 219.1 | 6.3 | 7.55 | ||||

| 323 168 | 12 | 323.9 | 7.1 | 6 | 168.3 | 4.5 | 203 | 11.00 |

| 323 219 | 8 | 219.1 | 6.3 | 11.10 | ||||

| 323 273 | 10 | 273 | 6.3 | 11.20 | ||||

Nominal Diameter |

Outside Diameter | End to End |

||

| D1*D2 | ||||

| DN | NPS | Series A | Series B | H |

| 20*15 | 3/4*1/2 | 26.9*21.3 | 25*18 | 38 |

| 20*10 | 3/4*3/8 | 26.9*17.3 | 25*14 | 38 |

| 25*20 | 1*3/4 | 33.7*26.9 | 32*25 | 51 |

| 25*15 | 1*1/2 | 33.7*21.3 | 32*18 | 51 |

| 32*25 | 1.1/4*1 | 42.4*33.7 | 38*32 | 51 |

| 32*20 | 1.1/4*3/4 | 42.4*26.9 | 38*25 | 51 |

| 32*15 | 1.1/4*1/2 | 42.4*21.3 | 38*18 | 51 |

| 40*32 | 1.1/2*1.1/4 | 48.3*42.4 | 45*38 | 64 |

| 40*25 | 1.1/2*1 | 48.3*33.7 | 45*32 | 64 |

| 40*20 | 1.1/2*3/4 | 48.3*26.9 | 45*25 | 64 |

| 40*15 | 1.1/2*1/2 | 48.3*21.3 | 45*18 | 64 |

| 50*40 | 2*1.1/2 | 60.3*48.3 | 57*45 | 76 |

| 50*32 | 2*1.1/4 | 60.3*42.4 | 57*38 | 76 |

| 50*25 | 2*1 | 60.3*33.7 | 57*32 | 76 |

| 50*20 | 2*3/4 | 60.3*26.9 | 57*25 | 76 |

| 65*50 | 2.1/2*2 | 73.0*60.3 | 76*57 | 89 |

| 65*40 | 2.1/2*1.1/2 | 73.0*48.3 | 76*45 | 89 |

| 65*32 | 2.1/2*1.1/4 | 73.0*42.4 | 76*38 | 89 |

| 65*25 | 2.1/2*1 | 73.0*33.7 | 76*32 | 89 |

| 80*65 | 3*2.1/2 | 88.9*73.0 | 89*76 | 89 |

| 80*50 | 3*2 | 88.9*60.3 | 89*57 | 89 |

| 80*40 | 3*1.1/2 | 88.9*48.3 | 89*45 | 89 |

| 80*32 | 3*1.1/4 | 88.9*42.4 | 89*38 | 89 |

| 90*80 | 3.1/2*3 | 101.6*88.9 | - | 102 |

| 90*65 | 3.1/2*2.1/2 | 101.6*73.0 | - | 102 |

| 90*50 | 3.1/2*2 | 101.6*60.3 | - | 102 |

| 90*40 | 3.1/2*1.1/2 | 101.6*48.3 | - | 102 |

| 90*32 | 3.1/2*1.1/4 | 101.6*42.4 | - | 102 |

| 100*90 | 4*3.1/2 | 114.3*101.6 | - | 102 |

| 100*80 | 4*3 | 114.3*88.9 | 108*89 | 102 |

| 100*65 | 4*2.1/2 | 114.3*73.0 | 108*76 | 102 |

| 100*50 | 4*2 | 114.3*60.3 | 108*57 | 102 |

| 100*40 | 4*1.1/2 | 114.3*48.3 | 108*45 | 102 |

| 125*100 | 5*4 | 141.3*114.3 | 133*108 | 127 |

| 125*90 | 5*3.1/2 | 141.3*101.6 | - | 127 |

| 125*80 | 5*3 | 141.3*88.9 | 133*89 | 127 |

| 125*65 | 5*2.1/2 | 141.3*73.0 | 133*76 | 127 |

| 125*50 | 5*2 | 141.3*60.3 | 133*57 | 127 |

| 150*125 | 6*5 | 168.3*141.3 | 159*133 | 140 |

| 150*100 | 6*5 | 168.3*114.3 | 159*108 | 140 |

| 150*90 | 6*3.1/2 | 168.3*101.6 | - | 140 |

| 150*80 | 6*3 | 168.3*88.9 | 159*89 | 140 |

| 150*65 | 6*2.1/2 | 168.3*73.0 | 159*76 | 140 |

| 200*150 | 8*6 | 219.1*168.3 | 219*159 | 152 |

| 200*125 | 8*5 | 219.1*141.3 | 219*133 | 152 |

| 200*100 | 8*4 | 219.1*114.3 | 219*108 | 152 |

| 200*90 | 8*3.1/2 | 219.1*101.6 | - | 152 |

| 250*200 | 10*8 | 273.0*219.1 | 273*219 | 178 |

| 250*150 | 10*6 | 273.0*168.3 | 273*159 | 178 |

| 250*125 | 10*5 | 273.0*141.3 | 273*133 | 178 |

| 250*100 | 10*4 | 273.0*114.3 | 273*108 | 178 |

| 300*250 | 12*10 | 323.9*273.1 | 325*273 | 203 |

| 300*200 | 12*8 | 323.9*219.1 | 325*219 | 203 |

| 300*150 | 12*6 | 323.9*168.3 | 325*159 | 203 |

| 300*125 | 12*5 | 323.9*141.3 | 325*133 | 203 |

| 350*300 | 14*12 | 355.6*323.9 | 377*325 | 330 |

| 350*250 | 14*10 | 355.6*273.0 | 377*273 | 330 |

| 350*200 | 14*8 | 355.6*219.1 | 377*219 | 330 |

| 350*150 | 14*6 | 355.6*168.3 | 377*159 | 330 |

| 400*350 | 16*14 | 406.4*355.6 | 426*377 | 356 |

| 400*300 | 16*12 | 406.4*323.9 | 426*325 | 356 |

| 400*250 | 16*10 | 406.4*273.0 | 426*273 | 356 |

| 400*200 | 16*8 | 406.4*219.1 | 426*219 | 356 |

| 450*400 | 18*16 | 457*406.4 | 478*426 | 381 |

| 450*350 | 18*14 | 457*355.6 | 478*377 | 381 |

| 450*300 | 18*12 | 457*323.9 | 478*325 | 381 |

| 450*250 | 18*10 | 457*273.0 | 478*273 | 381 |

| 500*450 | 20*18 | 508*457 | 529*478 | 508 |

| 500*400 | 20*16 | 508*406.4 | 529*426 | 508 |

| 500*350 | 20*14 | 508*355.6 | 529*377 | 508 |

| 500*300 | 20*12 | 508*323.9 | 529*325 | 508 |

| 550*500 | 22*20 | 559*508 | - | 508 |

| 550*450 | 22*18 | 559*457 | - | 508 |

| 550*400 | 22*16 | 559×406.4 | - | 508 |

| 550*350 | 22*14 | 559*355.6 | - | 508 |

| 600*550 | 24*22 | 610*559 | - | 508 |

| 600*500 | 24*20 | 610*508 | 630*529 | 508 |

| 600*450 | 24*18 | 610*457 | 630*478 | 508 |

| 600*400 | 24*22 | 610*406.4 | 630*426 | 508 |

| 650*600 | 26*24 | 660*610 | - | 610 |

| 650*550 | 26*22 | 660*559 | - | 610 |

| 650*500 | 26*20 | 660*508 | - | 610 |

| 650*450 | 26*18 | 660*457 | - | 610 |

| 700*650 | 28*26 | 711*660 | - | 610 |

| 700*600 | 28*24 | 711*610 | 720*630 | 610 |

| 700*550 | 28*22 | 711*559 | - | 610 |

| 700*500 | 28*20 | 711*508 | 720*530 | 610 |

| 750*700 | 30*28 | 762*711 | - | 610 |

| 750*650 | 30*26 | 762*660 | - | 610 |

| 750*600 | 30*24 | 762*610 | - | 610 |

| 750*550 | 30*22 | 762*559 | - | 610 |

| 800*750 | 32*30 | 813*762 | - | 610 |

| 800*700 | 32*28 | 813*711 | 820*720 | 610 |

| 800*650 | 32*26 | 813*660 | - | 610 |

| 800*600 | 32*24 | 813*610 | 820*630 | 610 |

| 850*800 | 34*32 | 864*813 | - | 610 |

| 850*750 | 34*30 | 864*762 | - | 610 |

| 850*700 | 34*28 | 864*711 | - | 610 |

| 850*650 | 34*26 | 864*660 | - | 610 |

| 900*850 | 36*34 | 914*864 | - | 610 |

| 900*800 | 36*32 | 914*813 | 920*820 | 610 |

| 900*750 | 36*30 | 914*762 | - | 610 |

| 900*700 | 36*28 | 914*711 | 920*720 | 610 |

| 950*900 | 38*36 | 965*914 | - | 610 |

| 950*850 | 38*34 | 965*864 | - | 610 |

| 950*800 | 38*32 | 965*813 | - | 610 |

| 950*750 | 38*30 | 965*762 | - | 610 |

| 1000*950 | 40*38 | 1016*965 | - | 610 |

| 1000*900 | 40*36 | 1016*914 | 1020*920 | 610 |

| 1000*850 | 40*34 | 1016*864 | - | 610 |

| 1000*800 | 40*32 | 1016*813 | 1020*820 | 610 |

| 1050*1000 | 42*40 | 1067*1016 | - | 610 |

| 1050*950 | 42*38 | 1067*965 | - | 610 |

| 1050*900 | 42*36 | 1067*914 | - | 610 |

| 1050*850 | 42*34 | 1067*864 | - | 610 |

| 1100*1050 | 44*42 | 1118*1067 | - | 610 |

| 1100*1000 | 44*40 | 1118*1016 | 1120*1020 | 610 |

| 1100*950 | 44*38 | 1118*965 | - | 610 |

| 1100*900 | 44*36 | 1118*914 | 1220*920 | 610 |

| 1150*1100 | 46*44 | 1168*1118 | - | 711 |

| 1150*1050 | 46*42 | 1168*1067 | - | 711 |

| 1150*1000 | 46*40 | 1168*1016 | - | 711 |

| 1150*950 | 46*38 | 1168*965 | - | 711 |

| 1200*1150 | 48*46 | 1220*1168 | - | 711 |

| 1200*1100 | 48*44 | 1220*1118 | 1220*1120 | 711 |

| 1200*1050 | 48*42 | 1220*1067 | - | 711 |

| 1200*1000 | 48*40 | 1220*1016 | 1220*1020 | 711 |

| Nominal Pipe Size | 1/2 to 2.1/2 | 3 to 3.1/2 | 4 | 5 to 8 |

| Outside Diameter at Bevel (D) |

+ 1.6 – 0.8 |

1.6 | 1.6 | + 2.4 – 1.6 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 |

| Overall Length (H) | 2 | 2 | 2 | 2 |

| Nominal Pipe Size | 10 to 18 | 20 to 24 | 26 to 30 | 32 to 48 |

| Outside Diameter at Bevel (D) |

+ 4 – 3.2 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Inside Diameter at End | 3.2 | 4.8 | + 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Overall Length (H) | 2 | 2 | 5 | 5 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||