Pipe Fittings SScm415 Chromoly Stub End Stainless Steel Stub End Pipe Fittings are buttweld fittings that can be used in combination with a lap joint flange. Alternatively the ASME B 16.9 Stub End can be used with welding neck flanges to make flanged connections. The use of Lap Joint Stub End has two advantages. One , the ANSI B 16.9 Stub End can reduce the total cost of flanged joints when used in a piping system in high material grades. This is because the lap joint flange does not need to be of the same material of the pipe while the Stub Ends B16.9 but could be a lower grade. And two , the Long Stub End speeds up the installation process. Since a lap joint flange can be rotated to smoothen the alignment of the bolt holes. Stub End Din 2642 fittings are available in short and long pattern i.e. - ASA and MSS ASME B16.9 Stub End .

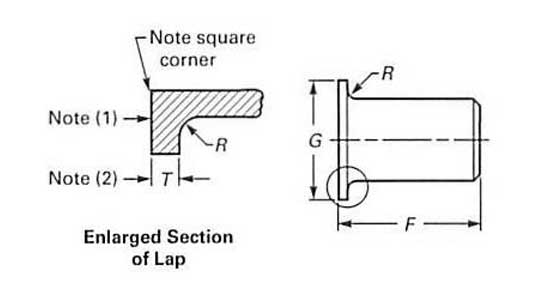

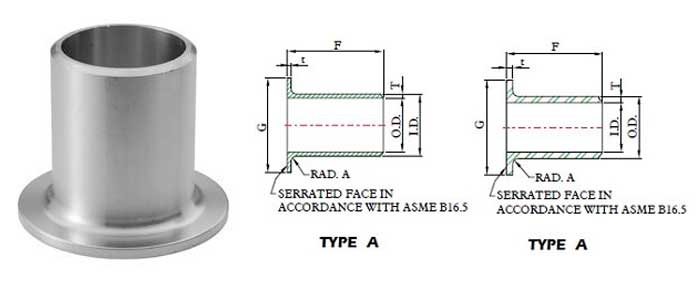

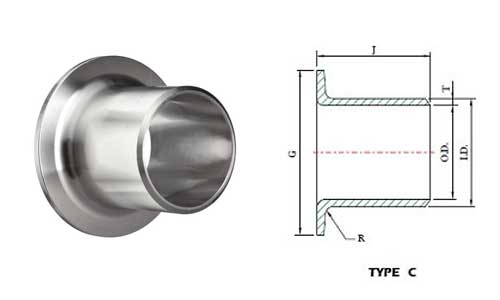

Stub End Buttweld Fittings are available in three different types. These ASME B16.9 Stub End can be labelled as - Stub End Type A , Mss Type B Stub End and Type C : The first type is the Stub End Sch 10 Type A fitting. This type A Stub Ends Specification has been manufactured and machined to match standard lap joint backing flange. This is because both the lap joint backing flange as well as the type A Stub End Jis 10k have to be used in combination. The mating surfaces of the Stub End Type A have an identical profile, which permits the smooth loading of the flare face Type B Stub Ends Stainless Steel are to be used with standard slip-on flanges. Stub End Carbon Steel in Type C could be used either way – i.e. - with lap joint or with slip-on flanges. These type C EN 1092-1 Stub End are manufactured from pipes. Ss Stub End Dimensions could be ordered with different finished ends such as Bevelled Ends, Grooved Ends, Squared Ends , Flanged Ends as well as Threaded Ends which are meant for Male fittings Only.

The Stub End EN 1092-1 Type 35, is essentially a piece of pipe, with one end flared outwards whereas the other end has to be prepared to be welded to a pipe which will be the same bore size or NPS i.e - nominal pipe size, material as well as wall thickness. The most extensively used fabrication tool for Type B Stub End Dimensions is the flaring machine. This machine is able to flare the end of the pipe of the Stub End EN 1092-1 Type 36 and then cuts it to length.

| Specifications | ASME B16.9 Stub End |

|---|---|

| Carbon Steel Stub Ends Fittings size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| Stub EndDimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Stub End Type A Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Stub End Mss Sp 43 Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Stainless Steel Stub End Pipe Fittings Type | DN15-DN1200 |

| Connection For Long Stub Ends | Welding |

| Short Stub End Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Lap Joint Stub End Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Stub End Type A Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D,

6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process for Stub End B16.9 | Push, Press, Forge, Cast, etc. |

| Stub End Buttweld Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills for Mss Type B Stub End | Stubs End Mss Sp 43 for Japanese, Long Stubs End for Indian, Short Stubs End for USA, Lap Joint Stubs End for Korean, Stubs End B16.9 for European, Stubs End Buttweld Fittings for Ukraine, Stubs End Din 2642 for Russian |

| Key markets and industries for ASME B 16.9 Stub End |

|

| ANSI B 16.9 Stub End Application |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

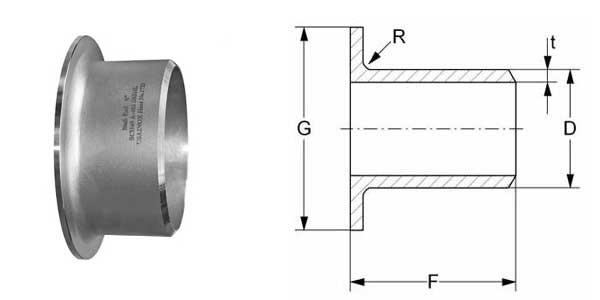

| Nominal Pipe Size | Outside diameter of barrel |

Length (F) | Radius (R) | Diameter (G) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Long Pattern |

Short Pattern |

|||

| 1/2″ | 20.5 | 22.8 | 76 | 51 | 3 | 35 |

| 3/4″ | 25.9 | 28.1 | 76 | 51 | 3 | 43 |

| 1″ | 32.6 | 35.0 | 102 | 51 | 3 | 51 |

| 1 1/4″ | 41.4 | 43.6 | 102 | 51 | 5 | 64 |

| 1 1/2″ | 47.5 | 49.9 | 102 | 51 | 6 | 74 |

| 2″ | 59.5 | 62.4 | 152 | 64 | 8 | 92 |

| 2 1/2″ | 72.2 | 75.3 | 152 | 64 | 8 | 105 |

| 3″ | 88.1 | 91.3 | 152 | 64 | 10 | 127 |

| 3 1/2″ | 100.8 | 104.0 | 152 | 76 | 10 | 140 |

| 4″ | 113.5 | 116.7 | 152 | 76 | 11 | 157 |

| 5″ | 140.5 | 144.3 | 203 | 76 | 11 | 186 |

| 6″ | 167.5 | 171.3 | 203 | 89 | 13 | 216 |

| 8″ | 218.3 | 222.1 | 203 | 102 | 13 | 270 |

| 10″ | 272.3 | 277.2 | 254 | 127 | 13 | 324 |

| 12″ | 323.1 | 328.0 | 254 | 152 | 13 | 381 |

| 14″ | 354.8 | 359.9 | 305 | 152 | 13 | 413 |

| 16″ | 405.6 | 411.0 | 305 | 152 | 13 | 470 |

| 18″ | 456.0 | 462.0 | 305 | 152 | 13 | 533 |

| 20″ | 507.0 | 514.0 | 305 | 152 | 13 | 584 |

| 22″ | 558.0 | 565.0 | 305 | 152 | 13 | 641 |

| 24″ | 609.0 | 616.0 | 305 | 152 | 13 | 692 |

|

STUB ENDS – ANSI B 16.9 and MSS SP-43 dimension |

|||||||

|---|---|---|---|---|---|---|---|

| inches | ND | mm | Diameter of lap |

Radius of fillet |

Length F | ||

|

D |

G | R | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| The lap thickness T shall not be less than nominal pipe wall thickness t | |||||||

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Long Pattern | Short Pattern | Radius of Fillet | Diameter of Lap | |

|---|---|---|---|---|---|---|

| Max | Min | F | F | R | G | |

| 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 35 |

| 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 43 |

| 1 | 35.0 | 32.6 | 102 | 51 | 3 | 51 |

| 1-1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 64 |

| 1-1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 73 |

| 2 | 62.4 | 59.5 | 152 | 64 | 8 | 92 |

| 2-1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 105 |

| 3 | 91.3 | 88.1 | 152 | 64 | 10 | 127 |

| 3-1/2 | 104.0 | 100.8 | 152 | 76 | 10 | 140 |

| 4 | 116.7 | 113.5 | 152 | 76 | 11 | 157 |

| 5 | 144.3 | 140.5 | 203 | 76 | 11 | 186 |

| 6 | 171.3 | 167.5 | 203 | 89 | 13 | 216 |

| 8 | 222.1 | 218.3 | 203 | 102 | 13 | 270 |

| 10 | 277.2 | 272.3 | 254 | 127 | 13 | 324 |

| 12 | 328.0 | 323.1 | 254 | 152 | 13 | 381 |

| 14 | 359.5 | 354.8 | 305 | 152 | 13 | 413 |

| 16 | 411.0 | 405.6 | 305 | 152 | 13 | 470 |

| 18 | 462 | 456 | 305 | 152 | 13 | 533 |

| 20 | 514 | 507 | 305 | 152 | 13 | 584 |

| 22 | 565 | 558 | 305 | 152 | 13 | 641 |

| 24 | 616 | 609 | 305 | 152 | 13 | 692 |

A Carbon Steel Stub End Fittings and a lap joint flange can be used together as an alternative way to make a flanged connection as opposed to welding neck flanges. The two devices that are to be combined, in this case, are:

| Product | Nom. Pipe Size | Dia (G) | Length (F), Short | Outside Dia (O.D.) | Sch 160, Inside Dia (I.D.) | Sch 160, Lap Thickness (t) | Schedule 160, Wall Thickness (T) | XX Strong Wall Approx. Weight | XX Strong Wall, Inside Dia (I.D.) |

|---|---|---|---|---|---|---|---|---|---|

| 1 1/2″ Stubs Ends Long Type “A | 1.5 | 2.875 | 2 | 1.9 | 1.338 | 0.281 | 0.281 | 2.98 | 1.1 |

| 1 1/2″ Stubs Ends Long Type “A” | 1.5 | 2.875 | 4 | 1.9 | 0.15 | 0.15 | 1.49 | 1.5 | 0.2 |

| 1 1/4″ Stubs Ends Long Type “A | 1.25 | 2.5 | 2 | 1.66 | 1.16 | 0.25 | 0.25 | 2.52 | 0.896 |

| 1 1/4″ Stubs Ends Long Types “A” | 1.25 | 2.5 | 4 | 1.66 | 0.14 | 0.14 | 1.26 | 1.278 | 0.191 |

| 1″ Stubs Ends Long Types “A | 1 | 2 | 2 | 1.315 | 0.815 | 0.25 | 0.25 | 1.76 | 0.599 |

| 1″ Stubs Ends Long Types “A” | 1 | 2 | 4 | 1.315 | 0.133 | 0.133 | 0.88 | 0.957 | 0.179 |

| 1/2″ Stubs Ends Long Types “A | 0.5 | 1.375 | 2 | 0.84 | 0.464 | 0.187 | 0.188 | 0.68 | 0.252 |

| 1/2″ Stubs Ends Long Types “A” | 0.5 | 1.375 | 3 | 0.84 | 0.109 | 0.109 | 0.34 | 0.546 | 0.147 |

| 10″ Stubs Ends Long Types “A | 10 | 12.75 | 5 | 10.75 | 8.5 | 1.125 | 1.125 | – | – |

| 10″ Stubs Ends Long Types “A” | 10 | 12.75 | 10 | 10.75 | 0.365 | 0.365 | 54 | 9.75 | 0.5 |

| 12″ Stubs Ends Long Types “A | 12 | 15 | 6 | 12.75 | 10.126 | 1.312 | 1.312 | – | – |

| 12″ Stubs Ends Long Types “A” | 12 | 15 | 10 | 12.75 | 0.375 | 0.375 | 64.5 | 11.75 | 0.5 |

| 14″ Stubs Ends Long Types “A” | 14 | 16.25 | 12 | 14 | 0.375 | 0.375 | 84 | 13 | 0.5 |

| 16″ Stubs Ends Long Types “A” | 16 | 18.5 | 12 | 16 | 0.375 | 0.375 | 98 | 15 | 0.5 |

| 18″ Stubs Ends Long Types “A” | 18 | 21 | 12 | 18 | 0.375 | 0.375 | 136 | 17 | 0.5 |

| 2 1/2″ Stubs Ends Long Types “A | 2.5 | 4.125 | 2.5 | 2.875 | 2.125 | 0.375 | 0.375 | 8.8 | 1.771 |

| 2 1/2″ Stubs Ends Long Types “A” | 2.5 | 4.125 | 6 | 2.875 | 0.203 | 0.203 | 4.4 | 2.323 | 0.276 |

| 2″ Stubs Ends Long Types “A | 2 | 3.625 | 2.5 | 2.375 | 1.689 | 0.343 | 0.343 | 6.1 | 1.503 |

| 2″ Stubs Ends Long Types “A” | 2 | 3.625 | 6 | 2.375 | 0.154 | 0.154 | 3.05 | 1.939 | 0.218 |

| 20″ Stubs Ends Long Types “A” | 20 | 23 | 12 | 20 | 0.375 | 0.375 | 157 | 19 | 0.5 |

| 3 1/2″ Stubs Ends Long Types “A | 3.5 | 5.5 | 3 | 4 | – | – | – | 15.5 | 2.728 |

| 3 1/2″ Stubs Ends Long Types “A” | 3.5 | 5.5 | 6 | 4 | 0.226 | 0.226 | 7.75 | 3.364 | 0.318 |

| 3″ Stubs Ends Long Types “A | 3 | 5 | 2.5 | 3.5 | 2.624 | 0.438 | 0.438 | 9.8 | 2.3 |

| 3″ Stubs Ends Long Types “A” | 3 | 5 | 6 | 3.5 | 0.216 | 0.216 | 6.5 | 2.9 | 0.3 |

| 3/4″ Stubs Ends Long Types “A | 0.75 | 1.688 | 2 | 1.05 | 0.612 | 0.218 | 0.219 | 0.94 | 0.434 |

| 3/4″ Stubs Ends Long Types “A” | 0.75 | 1.688 | 3 | 1.05 | 0.113 | 0.113 | 0.47 | 0.742 | 0.154 |

| 4″ Stubs Ends Long Types “A | 4 | 6.188 | 3 | 4.5 | 3.438 | 0.531 | 0.531 | 19.3 | 3.152 |

| 4″ Stubs Ends Long Types “A” | 4 | 6.188 | 6 | 4.5 | 0.237 | 0.237 | 9.65 | 3.826 | 0.337 |

| 5″ Stubs Ends Long Types “A | 5 | 7.313 | 3 | 5.563 | 4.313 | 0.625 | 0.625 | 32.66 | 4.063 |

| 5″ Stubs Ends Long Types “A” | 5 | 7.313 | 8 | 5.563 | 0.258 | 0.258 | 16.33 | 4.813 | 0.375 |

| 6″ Stubs Ends Long Types “A | 6 | 8.5 | 3.5 | 6.625 | 5.187 | 0.718 | 0.719 | 45.26 | 4.897 |

| 6″ Stubs Ends Long Types “A” | 6 | 8.5 | 8 | 6.625 | 0.28 | 0.28 | 22.63 | 5.761 | 0.432 |

| 8″ Stubs Ends Long Types “A | 8 | 10.625 | 4 | 8.625 | 6.813 | 0.906 | 0.906 | 59.71 | 6.875 |

| 8″ Stubs Ends Long Types “A” | 8 | 10.625 | 8 | 8.625 | 0.322 | 0.322 | 34.12 | 7.625 | 0.5 |

| Product | Nom. Pipe Size | Diameter (G) | Length (J) | Outside Diameter (O.D.) | Schedule 5S Approx. Weight | Schedule 5S, Inside Diameter (I.D.) | Schedule 5S, Wall Thickness (T) |

|---|---|---|---|---|---|---|---|

| 1 1/2″ Short Stubs Ends Short Type “C” | 1.5 | 2.875 | 2 | 1.9 | 0.29 | 1.77 | 0.065 |

| 1 1/4″ Short Stubs Ends Short Type “C” | 1.25 | 2.5 | 2 | 1.66 | 0.21 | 1.53 | 0.065 |

| 1″ Short Stubs Ends Short Type “C” | 1 | 2 | 2 | 1.315 | 0.19 | 1.185 | 0.065 |

| 1/2″ Short Stubs Ends Short Type “C” | 0.5 | 1.375 | 2 | 0.84 | 0.13 | 0.71 | 0.065 |

| 10″ Short Stubs Ends Short Type “C” | 10 | 12.75 | 5 | 10.75 | 7.48 | 10.482 | 0.134 |

| 12″ Short Stubs Ends Short Type “C” | 12 | 15 | 6 | 12.75 | 15 | 12.438 | 0.156 |

| 14″ Short Stubs Ends Short Type “C” | 14 | 16.25 | 6 | 14 | 19.2 | 13.688 | 0.156 |

| 16″ Short Stubs Ends Short Type “C” | 16 | 18.5 | 6 | 16 | 23.9 | 15.67 | 0.165 |

| 18″ Short Stubs Ends Short Type “C” | 18 | 21 | 6 | 18 | 28.5 | 17.67 | 0.165 |

| 2 1/2″ Short Stubs Ends Short Type “C” | 2.5 | 4.125 | 2.5 | 2.875 | 0.75 | 2.709 | 0.083 |

| 2″ Short Stubs Ends Short Type “C” | 2 | 3.625 | 2.5 | 2.375 | 0.44 | 2.245 | 0.065 |

| 20″ Short Stubs Ends Short Type “C” | 20 | 23 | 6 | 20 | 36.3 | 19.624 | 0.188 |

| 24″ Short Stubs Ends Short Type “C” | 24 | 27.25 | 6 | 24 | 56 | 23.564 | 0.218 |

| 3″ Short Stubs Ends Short Type “C” | 3 | 5 | 2.5 | 3.5 | 0.94 | 3.334 | 0.083 |

| 3/4″ Short Stubs Ends Short Type “C” | 0.75 | 1.688 | 2 | 1.05 | 0.14 | 0.92 | 0.065 |

| 4″ Short Stubs Ends Short Type “C” | 4 | 6.188 | 3 | 4.5 | 1.38 | 4.334 | 0.083 |

| 5″ Short Stubs Ends Short Type “C” | 5 | 7.313 | 3 | 5.563 | 2.06 | 5.345 | 0.109 |

| 6″ Short Stubs Ends Short Type “C” | 6 | 8.5 | 3.5 | 6.625 | 2.75 | 6.407 | 0.109 |

| 8″ Short Stubs Ends Short Type “C” | 8 | 10.625 | 4 | 8.625 | 3.88 | 8.407 | 0.109 |

| NPS inches |

STUB ENDS | |||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||

| NOMINAL PIPE SIZE (Inches) | NB | OD | THICKNESS | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 80 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 15NB | 21.30 | 1.65 | 2.11 | __ | 2.41 | 2.77 | 3.73 |

| 3/4 | 20NB | 26.70 | 1.65 | 2.11 | __ | 2.41 | 2.87 | 3.91 |

| 1 | 25NB | 33.40 | 1.65 | 2.77 | __ | 2.90 | 3.38 | 4.55 |

| 1 1/4 | 32NB | 42.20 | 1.65 | 2.77 | __ | 2.97 | 3.56 | 4.85 |

| 1 1/2 | 40NB | 48.30 | 1.65 | 2.77 | __ | 3.18 | 3.68 | 5.08 |

| 2 | 50NB | 60.30 | 1.65 | 2.77 | __ | 3.18 | 3.91 | 5.54 |

| 2 1/2 | 65NB | 73.00 | 2.11 | 3.05 | __ | 4.78 | 5.16 | 7.01 |

| 3 | 80NB | 88.90 | 2.11 | 3.05 | __ | 4.78 | 5.49 | 7.62 |

| 3 1/2 | 90NB | 101.60 | 2.11 | 3.05 | __ | 4.78 | 5.74 | 8.08 |

| 4 | 100NB | 114.30 | 2.11 | 3.05 | __ | 4.78 | 6.02 | 8.56 |

| 5 | 125NB | 141.30 | 2.77 | 3.40 | __ | __ | 6.55 | 9.53 |

| 6 | 150NB | 168.30 | 2.77 | 3.40 | __ | __ | 7.11 | 10.97 |

| 8 | 200NB | 219.10 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 12.70 |

| 10 | 250NB | 273.00 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 15.09 |

| 12 | 300NB | 323.80 | 3.96 | 4.57 | 6.35 | 8.38 | 10.31 | 17.48 |

| 14 | 350NB | 355.60 | 3.96 | 6.35 | 7.92 | 9.53 | 11.13 | 19.05 |

| 16 | 400NB | 406.40 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 | 21.44 |

| 18 | 450NB | 457.00 | 4.19 | 6.35 | 7.92 | 11.13 | 14.27 | 23.83 |

| 20 | 500NB | 508.00 | 4.78 | 6.35 | 9.53 | 12.70 | 15.09 | 26.19 |

| 22 | 550NB | 559.00 | 4.78 | 6.35 | 9.53 | 12.70 | __ | 28.58 |

| 24 | 600NB | 610.00 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 30.96 |

welded version = w

= s seamless execution

| Nominal | Schedule | D | t | G | F | R. Max. | kg / St. | |

|---|---|---|---|---|---|---|---|---|

| 1/2 “ | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 “ | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 “ | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 “ | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 “ | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 “ | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 “ | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 “ | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 “ | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 “ | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 “ | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 “ | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 “ | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 “ | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 “ | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 “ | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 “ | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 “ | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 “ | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |

| DIMENSIONAL TOLERANCES – STUB ENDS | ||||||

| For all fittings | Stub Ends | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Indide Ø at End | Wall Thickness t / t1 |

O.D. of Lap G | Fillet Radius of Lap – R | Overall Length. – F |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | +0 -1 | +0 -1 | 2 |

| 3 a 3 1/2 | 1 | 1,6 | less | +0 -1 | +0 -1 | 2 |

| 4 | +2 -1 | 1,6 | than | +0 -1 | +0 -2 | 2 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | +0 -1 | +0 -2 | 2 |

| 8 | 2 | 1,6 | of nominal | +0 -1 | +0 -2 | 2 |

| 10 | +4 -3 | 3,2 | tickness | +0 -2 | +0 -2 | 2 |

| 12 to 18 | +4 -3 | 3,2 | +0 -2 | +0 -2 | 3 | |

| 20 a 24 | +6 -5 | 4,8 | +0 -2 | +0 -2 | 3 | |

| 26 a 30 | +7 -5 | 4,8 | ||||

| 32 a 48 | +7 -5 | 4,8 | ||||