Pipe Fitings Titanium Butt weld Pipe Bend A Titanium butt weld pipe bend is a pipe fitting used to change the direction of the flow in a piping system. Butt weld pipe bends are designed to have a smooth curvature, providing a gradual change in direction to minimize pressure drops and turbulence. Here are key features and details about Titanium butt weld pipe bends

When using Titanium butt weld pipe bends, it's crucial to follow proper installation procedures, consider the specific requirements of the application, and adhere to industry standards. Consulting with professionals and adhering to relevant guidelines can provide specific details on the selection, installation, and maintenance of Titanium butt weld pipe bends in a given system.

| Standard |

(1.) ASME/ASTM – ASME B16.9, ASME B16.28, ASME B16.49, ASME B16.25, ISO3419,

ANSI/AWWA C208, MSS SP 75 (2.) DIN2605, EN 10253-1. EN 10253-2 |

| Size | Seamless: 1/2″ – 24″ One welding seam: 26″ – 36″ Two welding seam: 38″ – 72″ |

|---|---|

| Wall Thickness | 1.65mm to 80mm, SCH 5, SCH 10, SCH 40, SCH 80, SCH 100, SCH XS, SCH XXS, Custom Thickness |

| Type | Seamless, Welded, 100% X-Ray Welded or Fabricated, Miter Bends |

| ASME B16.25 – ‘Buttwelding Ends’ | |

| Surface Finish | Shot blasting, Black Phosphating, Black, Oiled, Paint, Hairline, Mirror, Galvanized, Anti Corrosive |

| End Type | Plain, Bevel, Screwed, Threaded |

| End Protection | Plastic Caps |

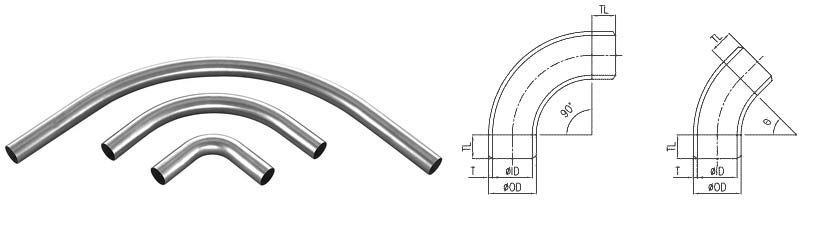

| NPS | O.D. D |

90° Long Rad Center to End A |

45° Long Rad Center to End B |

90° 3D Center to End A |

45° 3D Center to End B |

| 1/2 | 21.3 | 38 | 16 | ||

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| Gauge | Stainless Steel Minimum Bend Radius Includes Minimum Closeness of Cutout to Bend |

Stainless Bend Radius (Refers to Inner Radius) |

|---|---|---|

| 11 gauge (0.120″ |3.05mm) | .5″ | .07″, .08″, .09″, .1″, .125″ |

| 14 gauge (0.075″ | 1.9 mm) | .275″ | .05″, .055″, .062″, .07″, .075″ |

| .375″ | .07″, .105″ | |

| .5″ | .09″, .11″, .115″, .12″ | |

| 1.375″ | .4″ | |

| 16 gauge (0.060″ | 1.52 mm) | .2″ | .035″, .05″ |

| .265″ | .05″, .055″, .075″, .08″ | |

| .375″ | .07″ | |

| .5″ | .105″, .12″ | |

| 18 gauge (0.048″ | 1.22 mm) | .2″ | .04″, .045″, .05″ |

| .265″ | .06″, .07″, .08″, .085″ | |

| .375″ | .1″, .125″ | |

| .5″ | .115″, .12″ | |

| 20 gauge (0.035″ | 0.89 mm) | .2″ | .05″ |

| .265″ | .06″, .07″ | |

| .375″ | .095″ | |

| 22 gauge (0.029″ | 0.74 mm) | .2″ | .05″ |

| .265″ | .04″, .08″ | |

| 24 gauge (0.024″ | 0.61 mm) | .2″ | .04″ |

| .265″ | .08″ |

| Temperature, °C |

600

|

700

|

800

|

900

|

1000

|

| Tensile Strength, MPa | 380 | 270 | 170 | 90 | 50 |

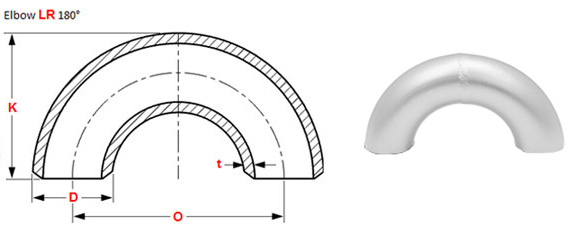

| NPS | O.D. D | 180° Long Radius | |

|---|---|---|---|

| Center to Center O |

Back to Face K |

||

| 1/2 | 21.3 | 76 | 48 |

| 3/4 | 26.7 | 76 | 51 |

| 1 | 33.4 | 76 | 56 |

| 1¼ | 42.2 | 95 | 70 |

| 1½ | 48.3 | 114 | 83 |

| 2 | 60.3 | 152 | 106 |

| 2½ | 73 | 190 | 132 |

| 3 | 88.9 | 229 | 159 |

| 3½ | 101.6 | 267 | 184 |

| 4 | 114.3 | 305 | 210 |

| 5 | 141.3 | 381 | 262 |

| 6 | 168.3 | 457 | 313 |

| 8 | 219.1 | 610 | 414 |

| 10 | 273 | 762 | 518 |

| 12 | 323.8 | 914 | 619 |

| 14 | 355.6 | 1067 | 711 |

| 16 | 406.4 | 1219 | 813 |

| 18 | 457 | 1372 | 914 |

| 20 | 508 | 1524 | 1016 |

| 22 | 559 | 1676 | 1118 |

| 24 | 610 | 1829 | 1219 |

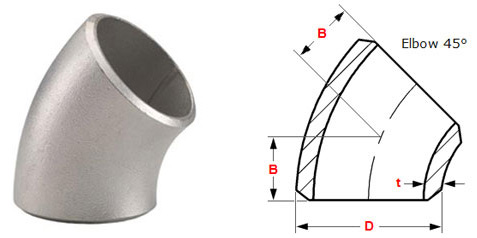

| NPS | O.D. D |

45 degrees Long Radius Center-to-End A |

45 degrees 3D Center-to-End A |

| 1/2 | 21.3 | 38 | – |

| 3/4 | 26.7 | 38 | 57 |

| 1 | 33.4 | 38 | 76 |

| 1¼ | 42.2 | 48 | 95 |

| 1½ | 48.3 | 57 | 114 |

| 2 | 60.3 | 76 | 152 |

| 2½ | 73 | 95 | 190 |

| 3 | 88.9 | 114 | 229 |

| 3½ | 101.6 | 133 | 267 |

| 4 | 114.3 | 152 | 305 |

| 5 | 141.3 | 190 | 381 |

| 6 | 168.3 | 229 | 457 |

| 8 | 219.1 | 305 | 610 |

| 10 | 273 | 381 | 762 |

| 12 | 323.8 | 457 | 914 |

| 14 | 355.6 | 533 | 1067 |

| 16 | 406.4 | 610 | 1219 |

| 18 | 457 | 686 | 1372 |

| 20 | 508 | 762 | 1524 |

| 22 | 559 | 838 | 1676 |

| 24 | 610 | 914 | 1829 |

| 26 | 660 | 991 | 1981 |

| 28 | 711 | 1067 | 2134 |

| 30 | 762 | 1143 | 2286 |

| 32 | 813 | 1219 | 2438 |

| 34 | 864 | 1295 | 2591 |

| 36 | 914 | 1372 | 2743 |

| 38 | 965 | 1448 | 2896 |

| 40 | 1016 | 1524 | 3048 |

| 42 | 1067 | 1600 | 3200 |

| 44 | 1118 | 1676 | 3353 |

| 46 | 1168 | 1753 | 3505 |

| 48 | 1219 | 1829 | 3658 |

| Thickness | Minimum Bend | Bend Radius | ||||

|---|---|---|---|---|---|---|

| Gauge | Inch | mm | Inch | mm | Inch | mm |

| 24 | (0.025″) | 0.635 | 0.2″ | 5.08 | 0.04″ | 1.02 |

| 24 | (0.025″) | 0.635 | 0.265″ | 6.73 | 0.08″ | 2.03 |

| 24 | (0.025″) | 0.635 | 0.5″ | 12.7 | 0.1″ | 2.54 |

| 22 | (0.031″) | 0.787 | 0.265″ | 6.73 | 0.075″ | 1.9 |

| 22 | (0.031″) | 0.787 | 0.55″ | 13.97 | 0.03″ | 0.76 |

| 22 | (0.031″) | 0.787 | 0.265″ | 6.73 | 0.04″ | 1.02 |

| 22 | (0.031″) | 0.787 | 0.265″ | 6.73 | 0.08″ | 2.03 |

| 22 | (0.031″) | 0.787 | 0.265″ | 6.73 | 0.08″ | 2.03 |

| 22 | (0.031″) | 0.787 | 0.2″ | 5.08 | 0.04″ | 1.02 |

| 22 | (0.031″) | 0.787 | 0.375″ | 9.52 | 0.08″ | 2.03 |

| 22 | (0.031″) | 0.787 | 0.2″ | 5.08 | 0.05″ | 1.27 |

| 20 | (0.038″) | 0.965 | 0.265″ | 6.73 | 0.07″ | 1.78 |

| 20 | (0.038″) | 0.965 | 0.23″ | 5.84 | 0.04″ | 1.02 |

| 20 | (0.038″) | 0.965 | 0.265″ | 6.73 | 0.07″ | 1.78 |

| 20 | (0.038″) | 0.965 | 0.5″ | 12.7 | 0.1″ | 2.54 |

| 20 | (0.038″) | 0.965 | 0.265″ | 6.73 | 0.07″ | 1.78 |

| 20 | (0.038″) | 0.965 | 0.265″ | 6.73 | 0.06″ | 1.52 |

| 20 | (0.038″) | 0.965 | 0.2″ | 5.08 | 0.05″ | 1.27 |

| 20 | (0.038″) | 0.965 | 0.375″ | 9.52 | 0.095″ | 2.41 |

| 20 | (0.038″) | 0.965 | 0.2″ | 5.08 | 0.05″ | 1.27 |

| 20 | (0.038″) | 0.965 | 0.5″ | 12.7 | 0.11″ | 2.79 |

| 20 | (0.038″) | 0.965 | 0.2″ | 5.08 | 0.05″ | 1.27 |

| 20 | (0.038″) | 0.965 | 0.225″ | 5.71 | 0.049″ | 1.24 |

| 18 | (0.05″) | 1.27 | 0.375″ | 9.52 | 0.1″ | 2.54 |

| 18 | (0.05″) | 1.27 | 0.265″ | 6.73 | 0.07″ | 1.78 |

| 18 | (0.05″) | 1.27 | 0.5″ | 12.7 | 0.115″ | 2.92 |

| 18 | (0.05″) | 1.27 | 0.265″ | 6.73 | 0.06″ | 1.52 |

| 18 | (0.05″) | 1.27 | 0.265″ | 6.73 | 0.06″ | 1.52 |

| 18 | (0.05″) | 1.27 | 0.265″ | 6.73 | 0.085″ | 2.16 |

| 18 | (0.05″) | 1.27 | 0.375″ | 9.52 | 0.125″ | 3.17 |

| 18 | (0.05″) | 1.27 | 0.5″ | 12.7 | 0.04″ | 1.02 |

| 18 | (0.05″) | 1.27 | 0.25″ | 6.35 | 0.045″ | 1.14 |

| 18 | (0.05″ | 1.27 | 0.2″ | 5.08 | 0.045″ | 1.14 |

| 18 | (0.05″ | 1.27 | 0.5″ | 12.7 | 0.24″ | 6.1 |

| 18 | (0.05″ | 1.27 | 0.265″ | 6.73 | 0.062″ | 1.57 |

| 18 | (0.05″ | 1.27 | 1.375″ | 34.92 | 0.4″ | 10.16 |

| 18 | (0.05″ | 1.27 | 0.265″ | 6.73 | 0.08″ | 2.03 |

| 18 | (0.05″ | 1.27 | 0.265″ | 6.73 | 0.08″ | 2.03 |

| 18 | (0.05″ | 1.27 | 0.2″ | 5.08 | 0.04″ | 1.02 |

| 18 | (0.05″ | 1.27 | 0.375″ | 9.52 | 0.07″ | 1.78 |

| 18 | (0.05″ | 1.27 | 0.5″ | 12.7 | 0.12″ | 3.05 |

| 18 | (0.05″ | 1.27 | 0.2″ | 5.08 | 0.05″ | 1.27 |

| 16 | (0.063″ | 1.60 | 0.2″ | 5.08 | 0.05″ | 1.27 |

| 16 | (0.063″ | 1.60 | 0.265″ | 6.73 | 0.08″ | 2.03 |

| 16 | (0.063″ | 1.60 | 0.265″ | 6.73 | 0.05″ | 1.27 |

| 16 | (0.063″ | 1.60 | 0.2″ | 5.08 | 0.04″ | 1.02 |

| 16 | (0.063″ | 1.60 | 0.375″ | 9.52 | 0.07″ | 1.78 |

| 16 | (0.063″ | 1.60 | 0.2″ | 5.08 | 0.035″ | 0.89 |

| 16 | (0.063″ | 1.60 | 0.265″ | 6.73 | 0.055″ | 1.4 |

| 16 | (0.063″ | 1.60 | 0.375″ | 9.52 | 0.07″ | 1.78 |

| 16 | (0.063″ | 1.60 | 0.5″ | 12.7 | 0.25″ | 6.35 |

| 16 | (0.063″ | 1.60 | 0.265″ | 6.73 | 0.075″ | 1.9 |

| 16 | (0.063″ | 1.60 | 0.265″ | 6.73 | 0.055″ | 1.4 |

| 16 | (0.063″ | 1.60 | 0.5″ | 12.7 | 0.12″ | 3.05 |

| 16 | (0.063″ | 1.60 | 0.265″ | 6.73 | 0.08″ | 2.03 |

| 16 | (0.063″ | 1.60 | 0.2″ | 5.08 | 0.05″ | 1.27 |

| 16 | (0.063″ | 1.60 | 0.5″ | 12.7 | 0.1″ | 2.54 |

| 16 | (0.063″ | 1.60 | 0.285″ | 7.24 | 0.05″ | 1.27 |

| 16 | (0.063″ | 1.60 | 0.265″ | 6.73 | 0.061″ | 1.55 |

| 16 | (0.063″ | 1.60 | 0.5″ | 12.7 | 0.105″ | 2.67 |

| 14 | (0.078″ | 1.981 | 0.275″ | 6.98 | 0.05″ | 1.27 |

| 14 | (0.078″ | 1.981 | 0.5″ | 12.7 | 0.09″ | 2.29 |

| 14 | (0.078″ | 1.981 | 0.375″ | 9.52 | 0.07″ | 1.78 |

| 14 | (0.078″ | 1.981 | 0.5″ | 12.7 | 0.13″ | 3.3 |

| 14 | (0.078″ | 1.981 | 0.275″ | 6.98 | 0.055″ | 1.4 |

| 14 | (0.078″ | 1.981 | 0.5″ | 12.7 | 0.12″ | 3.05 |

| 14 | (0.078″ | 1.981 | 0.275″ | 6.98 | 0.05″ | 1.27 |

| 14 | (0.078″ | 1.981 | 0.275″ | 6.98 | 0.062″ | 1.57 |

| 14 | (0.078″ | 1.981 | 0.275″ | 6.98 | 0.075″ | 1.9 |

| 14 | (0.078″ | 1.981 | 0.5″ | 12.7 | 0.115″ | 2.92 |

| 14 | (0.078″ | 1.981 | 1.375″ | 34.92 | 0.4″ | 10.16 |

| 14 | (0.078″ | 1.981 | 0.351″ | 8.92 | 0.078″ | 1.98 |

| 14 | (0.078″ | 1.981 | 0.5″ | 12.7 | 0.115″ | 2.92 |

| 14 | (0.078″ | 1.981 | 0.5″ | 12.7 | 0.11″ | 2.79 |

| 14 | (0.078″ | 1.981 | 0.375″ | 9.52 | 0.105″ | 2.67 |

| 12 | (0.109″ | 2.769 | 0.5″ | 12.7 | 0.06″ | 1.52 |

| 12 | (0.109″ | 2.769 | 0.5″ | 12.7 | 0.095″ | 2.41 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.1″ | 2.54 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.125″ | 3.17 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.09″ | 2.29 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.1″ | 2.54 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.09″ | 2.29 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.125″ | 3.17 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.09″ | 2.29 |

| 11 | (0.120″ | 3.0448 | 0.5″ | 12.7 | 0.09″ | 2.29 |

| Nominal Pipe Size | 1/2 to 2½ | 3 to 3½ | 4 | 5 to 8 |

| Outside Diameter at Bevel (D) |

+ 1.6 – 0.8 |

1.6 | 1.6 | + 2.4 – 1.6 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 |

| Center to End LR (A/B) | 2 | 2 | 2 | 2 |

| Center to End 3D (A/B) | 3 | 3 | 3 | 3 |

| Nominal Pipe Size | 10 to 18 | 20 to 24 | 26 to 30 | 32 to 48 |

| Outside Diameter at Bevel (D) |

+ 4 – 3.2 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Inside Diameter at End | 3.2 | 4.8 | + 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Center to End LR (A/B) | 2 | 2 | 3 | 5 |

| Center to End 3D (A/B) | 3 | 3 | 6 | 6 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||