Mild steel forged fittings are components used in piping systems for connecting, branching, terminating, or changing the direction of pipelines. These fittings are typically manufactured by forging, a metalworking process that involves the shaping of metal using localized compressive forces. Mild steel is a type of carbon steel that contains a low amount of carbon, making it more ductile and malleable than higher carbon steels. Forged fittings are known for their strength and durability, and they are commonly used in various industries, including oil and gas, petrochemical, power generation, and water treatment. Mild steel forged fittings are suitable for applications where moderate strength and corrosion resistance are sufficient.

Elbow: Used for changing the direction of a pipeline.

Tee: Used to create branches in a piping system, forming a T-shape.

Cross: Similar to a tee but with an additional outlet to create a cross shape.

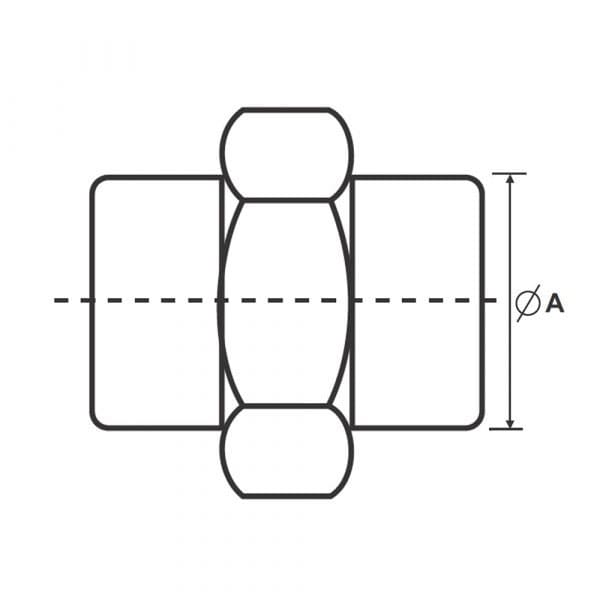

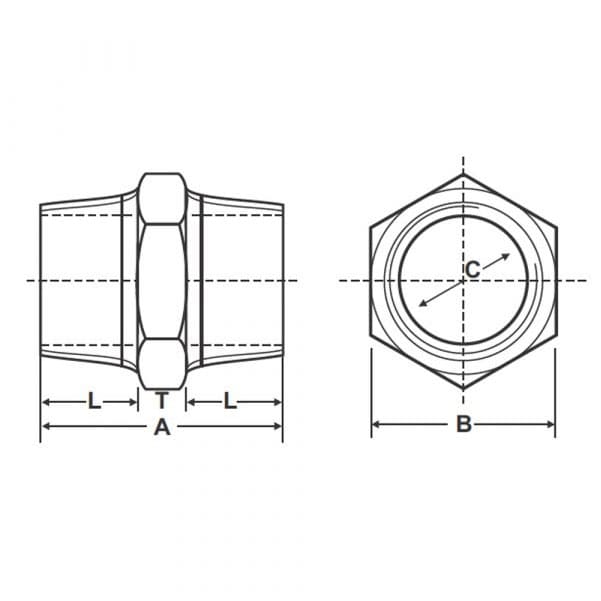

Coupling: Used to connect two pipes of the same diameter.

Union: A threaded coupling with a nut that allows for easy disassembly of pipes.

Bushings: Used to reduce the size of a threaded opening.

Cap: Used to close the end of a pipe.

Plug: Similar to a cap but designed for threaded openings.

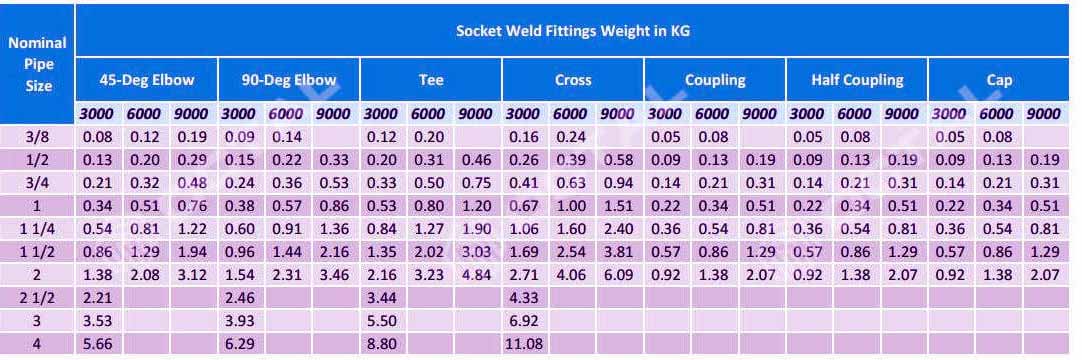

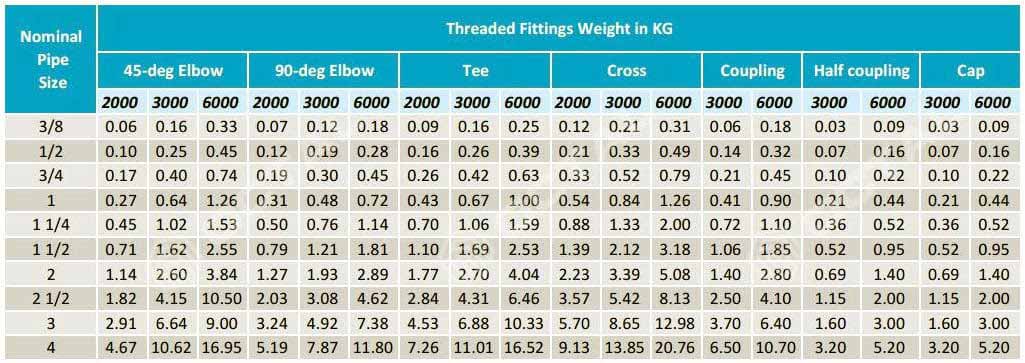

Mild steel forged fittings are often available in various pressure ratings (class ratings), such as 3000#, 6000#, and 9000#. The numbers indicate the maximum pressure in pounds per square inch (psi) that the fitting can handle.When using mild steel forged fittings, it's essential to consider factors such as the application, pressure requirements, and environmental conditions to ensure proper performance and longevity. Additionally, proper installation and maintenance practices should be followed to ensure the integrity of the piping system.

| Specification Chart: | Mild Steel Forged Fittings |

|---|---|

| Material | Mild Steel |

| Thickness | Customize Millimeter (mm) |

| Diameter | Customize Millimeter (mm) |

| Price | 300 INR/Unit |

| Minimum Order Quantity | 50 Piece |

| Supply Ability | 150000 Piece Per Month |

| Delivery Time | 1 Days (In Mumbai) And 2-3 Days (In India) |

| Packaging Details | As per requirement |

| Pressure Class | SW Fitting = Class 3000/ Class 6000/ Class 9000 NPT Fitting = Class 2000/ Class 3000/ Class 6000 |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged/ Heat treated and machined |

| Our service | Nace Mr 01 75 Sour Service Impact Test As Per Ug 84 Macro Structure Analysis Hydrogen Induce Cracking Test (Hic) Sulphide Stress Cracking Test (Sscc) Cryogenic Services (Cryo),hydrogen Services (H2) Helieum Leak Test Dye Peniterant Test (Dp) Magnetic Partius Test (Mp) Post Weld Heat Treatment (Pwht) Ultrasonic Test (Ut) Hydro Test, Etc. |

| Manufacturer Types | Elbow (45 Deg/ 90 Deg) Coupling (Full/ Half) Cross (Equal/ Reducing) Union (Male/Female), Outlet (Lateral/Branch) Tee (Equal/ Reducing) Threaded Pipe Cap Plug (Hex Head/ Square Head/ Round Head/ Bull) . |

| Method Types | Threaded (NPT) Socket Weld BSPT BSP |

| Type Of Standards | Bs3799 ASME B16.11 MSS SP 83 MSS SP 95 MSS SP 79 JIS B2302 |

| Manufacturer Size | SW Fitting = ½” Inch To 8” Inch Threaded (NPT) Fitting = ½” Inch To 8” Inch |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Nominal Outlet Size | Length Of (A) Minimum |

|---|---|

| 8 | 44 |

| 10 | 51 |

| 15 | 57 |

| 20 | 67 |

| 25 | 76 |

| 32 | 85 |

| 40 | 100 |

| 50 | 110 |

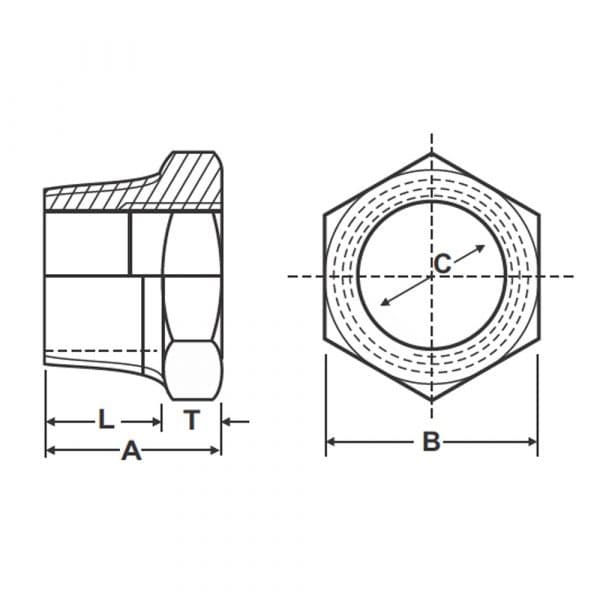

| Nominal Size Of Bore | Min. Length of Thread (L) | Hexagon Thickness (T) | Overall Length Of (A) Minimum | Bore Diameter (C) Minimum | Width Across Flat of Hexagon (B) |

|---|---|---|---|---|---|

| 8 | 12.5 | 6 | 31 | 6.5 | 15.5 |

| 10 | 12.5 | 8 | 33 | 9.5 | 17.9 |

| 15 | 17.5 | 8 | 43 | 12.5 | 23 |

| 20 | 19 | 10 | 48 | 19 | 27.8 |

| 25 | 21 | 10 | 52 | 25 | 35.3 |

| 32 | 24 | 11 | 59 | 32 | 47.2 |

| 40 | 24 | 13 | 61 | 38 | 52 |

| 50 | 27 | 14 | 68 | 51 | 61.1 |

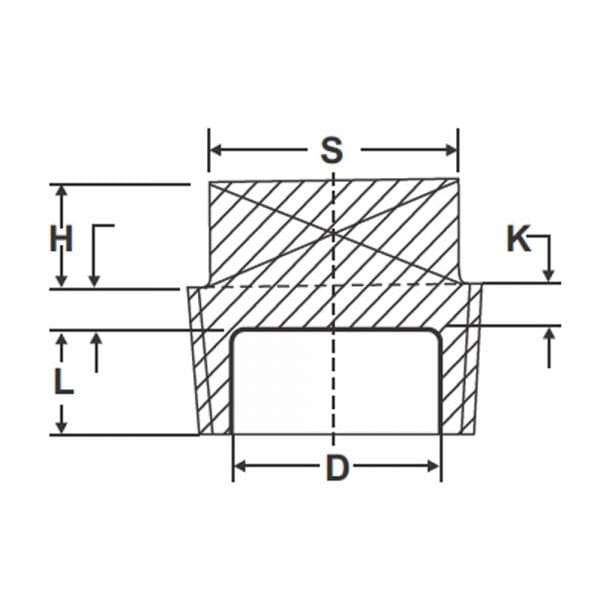

| Nominal Outlet Size | Thread Length Of (L) Minimum | Square Size (S) | Square Height (H) | Internal Diameter Of (D) Maximum |

|---|---|---|---|---|

| 6 | 6.5 | 6 | 6 | – |

| 8 | 9.7 | 9 | 6 | – |

| 10 | 10.1 | 11 | 10 | – |

| 15 | 13.2 | 13 | 10 | – |

| 20 | 14.5 | 14 | 12 | – |

| 25 | 16.8 | 17 | 12 | 22 |

| 32 | 19.1 | 22 | 16 | 31 |

| 40 | 19.1 | 27 | 16 | 33 |

| 50 | 23.4 | 32 | 19 | 48 |

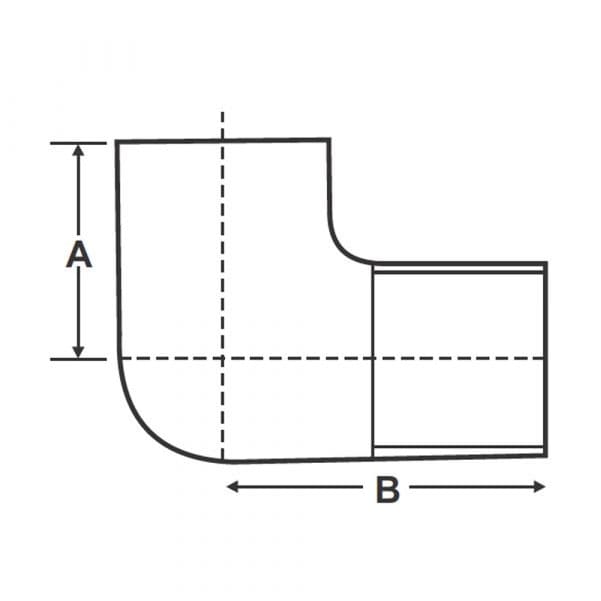

| Nominal Outlet Size | Length For Center to Face (A) (Minimum) | Length For Center to face (B) (Minimum) | Bore of Male End (Minimum) | Bore of Male End (Maximum) |

|---|---|---|---|---|

| 8 | 19 | 27 | 6.5 | 8 |

| 10 | 21 | 29 | 8.5 | 10.5 |

| 15 | 25 | 35 | 11.5 | 13 |

| 20 | 30 | 40 | 18 | 21 |

| 25 | 37 | 46 | 24 | 26 |

| 32 | 43 | 54 | 30 | 32 |

| 40 | 49 | 57 | 37 | 39 |

| 50 | 59 | 70 | 48 | 51 |

| External Threads Nominal Size | Internal Threads Nominal Size | Length of Threads | Hexagon Thickness (T) Maximum | Overall Length Of (A) Minimum | Hexagon (B) Width Across Flats |

|---|---|---|---|---|---|

| 8 | 6 | 12.5 | 6 | 18.5 | 15.5 |

| 10 | 8 | 12.5 | 7 | 20.5 | 17.9 |

| 15 | 8 | 17.5 | 8 | 25.5 | 23.0 |

| 15 | 10 | 17.5 | 7 | 25.5 | 23.0 |

| 15 | 10 | 19 | 10 | 29 | 27.8 |

| 20 | 15 | 19 | 10 | 29 | 27.8 |

| 25 | 15 | 21 | 10 | 31 | 35.3 |

| 25 | 20 | 21 | 10 | 31 | 35.3 |

| 32 | 15 | 24 | 11 | 35 | 47.2 |

| 32 | 20 | 24 | 11 | 35 | 47.2 |

| 32 | 25 | 24 | 11 | 35 | 47.2 |

| 40 | 20 | 24 | 13 | 37 | 52.0 |

| 40 | 25 | 24 | 13 | 37 | 52.0 |

| 40 | 32 | 24 | 13 | 37 | 52.0 |

| 50 | 25 | 27 | 14 | 41 | 61.1 |

| 50 | 32 | 27 | 14 | 41 | 61.1 |

| 50 | 40 | 27 | 14 | 41 | 61.1 |

| Product Description | Pressure Class (#) | ||

| Class 2000 Fitting | Class 3000 Fitting | Class 6000 Fitting | |

| ASME B16.11 Elbow ASME B16.11 Tee/ ASME B16.11 Cross/ ASME B16.11 Coupling ASME B16.11 Bushing/ End Cap |

1/2 - 4" | 1/2 - 2" | 1/2 - 2" |

| 1/2 - 4" | 1/2 - 2" | 1/2 - 2" | |

| 1/2 - 4" | 1/2 - 2" | 1/2 - 2" | |

| Wall Thickness Of Steel Pipe | 80 Sch | 160 Sch | XXS |

| Dimensions Of MS Forged Fittings | Up to 2" (Size) NB | 2 1/2" & 3" (Size)NB | |

| • Bore Of Socket Weld | + 0.25 | + 0.38 | |

| - 0.00 | - 0.00 | ||

| • Body Bore | + 0.00 | + 0.00 | |

| - 1.52 | - 3.00 | ||

| A | 1/4" NB (Size) | ± 0.8 | ± 2.50 |

| 3/8" TO 3/4" NB (Size) | ± 1.6 | ||

| 1"T0 2"NB (Size) | ± 2.0 | ||

| Chemicals | Content (%) |

| Sulfur, (S) | 0.03 |

| Molybdenum, (Mo) | 3-4 |

| Phosphorous, (P) | 0.045 |

| Manganese, (Mn) | 2 |

| Iron, (Fe) | Balance |

| Silicon, (Si) | 1 |

| Chromium, (Cr) | 18-20 |

| Carbon, (C) | 0.03 |

| Nickel, (Ni) | 11-15 |

| Properties | Metric | Imperial |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Yield Properties | 260 MPa | 37700 psi |

| Hardness, Rockwell B | 85 | 85 |

| Tensile Properties | 595 MPa | 86300 psi |

| Elongation at break (in 50 mm) | 55% | 55% |

| Modulus of elasticity | 200 GPa | 29000 ksi |