Super Duplex pipe fittings are components used to connect and control the flow of fluids in a piping system made from Super Duplex stainless steel. These fittings are designed to withstand corrosive environments and high-pressure conditions. Here are some common types of Super Duplex pipe fittings:

some common types of Super Duplex pipe fittings :

Elbows are fittings that allow the change in the direction of the pipe. Super Duplex elbows are designed to provide a smooth flow of fluids while maintaining the corrosion resistance of the material.

Tees are used to create a branch connection in a piping system. Super Duplex tees provide a strong and corrosion-resistant junction point for pipes.

Reducers are fittings used to connect pipes of different sizes. Super Duplex reducers are essential for maintaining a proper flow rate while transitioning between pipes with different diameters.

Stub ends are used in conjunction with lap joint flanges to create a removable connection point in the piping system. Super Duplex stub ends offer corrosion resistance and durability.

Cross fittings provide a way to connect four pipes at a common point. Super Duplex crosses are designed to handle the high-strength and corrosion-resistant requirements of demanding applications.

Couplings are used to connect two pipes of the same diameter. Super Duplex couplings ensure a secure and leak-proof connection in corrosive environments.

Caps and plugs are used to close the end of a pipe. Super Duplex caps and plugs provide a corrosion-resistant seal for the pipe ends.

Super Duplex Pipe Fittings Super Duplex stainless steel is a type of stainless steel that has a higher alloy content compared to standard duplex grades. It is known for its excellent corrosion resistance and high strength. Super Duplex stainless steel typically contains a combination of austenitic and ferritic phases in its microstructure. When working with Super Duplex pipe fittings, it's essential to follow industry standards and manufacturer recommendations for installation, welding, and maintenance.

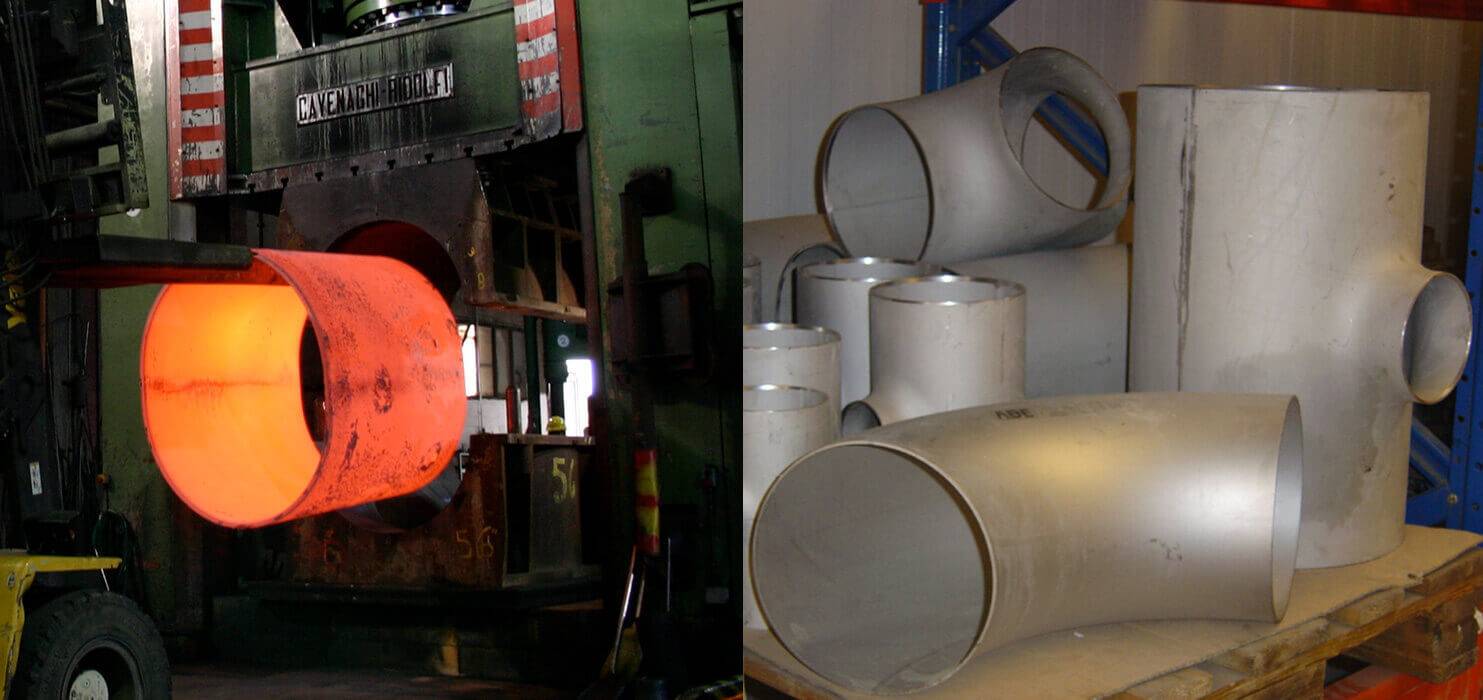

Super Duplex Steel S32750 Butt weld Fittings are pipe fittings made from Super Duplex Stainless Steel S32750, a high-performance alloy with excellent corrosion resistance, high strength, and good weldability. These fittings are used to connect pipes of various sizes and configurations in piping systems & they are designed to withstand high pressure and temperature conditions.

The benefits of using Super Duplex Steel S32750 Butt weld Fittings include high resistance to various forms of corrosion, excellent mechanical strength & durability. These fittings are also suitable in harsh environments with high temperatures and pressures, making them ideal for the oil, gas, chemical, and petrochemical industries. They offer good weldability, ease of fabrication, and long service life, making them a cost-effective solution in the long run.

| Specifications : | ASTM A815 / ASME SA815 |

| Dimensions : | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Size : | 1/2” NB to 24″NB in |

| Type : | Seamless / Welded / Fabricated |

| Grades : | Super Duplex S32750, S32760 |

| Products | Size | |

| ASTM A815 Super Duplex Steel Elbow – Long Radius | ASTM A815 Super Duplex Steel Stub Ends | Sizes 1/2″ – 48″ |

| ASTM A815 Super Duplex Steel Elbow – Short Radius | ASTM A815 Super Duplex Steel Cross | |

| ASTM A815 Super Duplex Steel Reducing Elbow | ASTM A815 Super Duplex Steel Reducing Cross | |

| ASTM A815 Super Duplex Steel 45° Elbow | ASTM A815 Super Duplex Steel Tees | |

| ASTM A815 Super Duplex Steel Fabricated Tee | ASTM A815 Super Duplex Steel End Cap | |

| ASTM A815 Super Duplex Steel Reducer | ASTM A815 Super Duplex Steel Coupling | |

| ASTM A815 Super Duplex Steel Concentric Reducer | ASTM A815 Super Duplex Steel Pipe Nipple | |

| ASTM A815 Super Duplex Steel Eccentric Reducer | ASTM A815 Super Duplex Steel 5D Elbow | |

| ASTM A815 Super Duplex Steel 3D Elbow | ASTM A815 Super Duplex Steel Welded Pipe Fittings | |

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |